Active enzyme model compound, and foliage fertilizer and synergist based on same, and using method of synergist

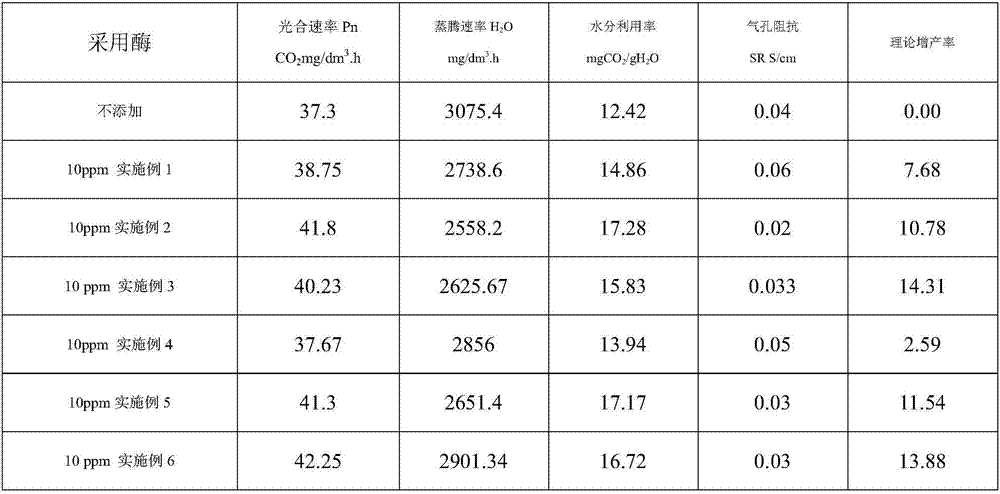

A model compound and active enzyme technology, applied in the agricultural field, can solve the problems of complex synthesis or extraction process, and achieve the effects of improving water utilization rate, improving survival rate, and good disaster resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of Active Enzyme Model Compound 1

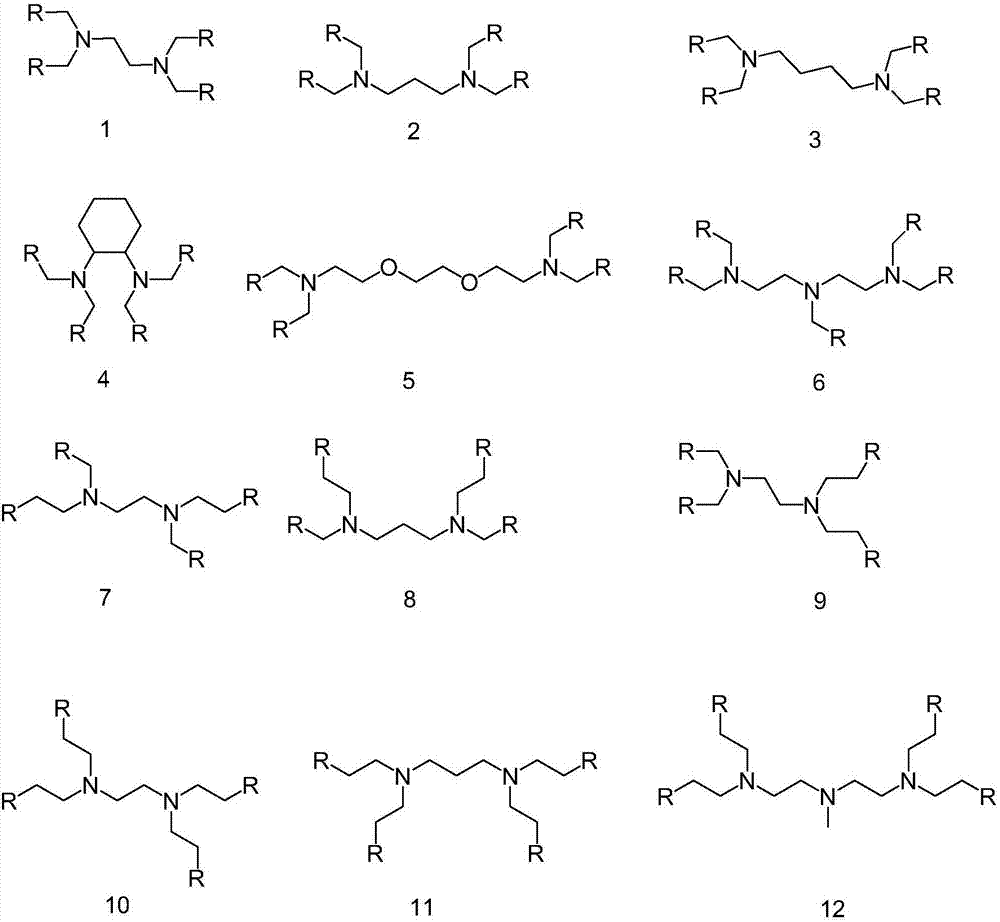

[0033] 1,2-Cyclohexylaminetetraacetic acid (CTA) and 2-mercaptoaniline are mixed at a mass ratio of 1:4, milled and mixed evenly, then put into a converter, and thermally condensed at 170°C for 8 hours until no water vapor is released until. After the condensation product was cooled to 50°C, it was put into an equal mass of absolute ethanol, stirred and left still, filtered, and the crude product was washed with distilled water, ethanol and ether, and dried at low temperature to obtain a white powder, which was ligand 4C, and the conversion rate was 67 %. The structure of ligand 4C is: .

[0034] Among them, R is

[0035] HRMS(ESI+)m / z calculated for C 38 h 35 N 6 S 4 (M+H):703.1806, found703.1811.

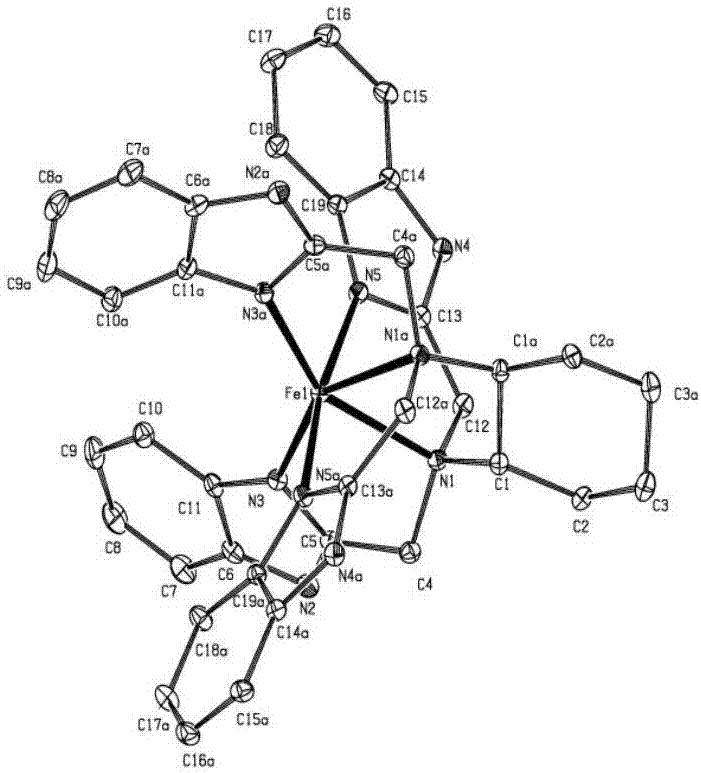

[0036] Ligand 4C and Fe(NO 3 ) 3 9H 2 O was mixed according to the mass ratio of 1:1.3, added to 2 times the mass of 95% ethanol, stirred and reacted at 60°C for 4 hours, cooled, filtered, and dried to obtain so...

Embodiment 2

[0038] Diethylenetriaminepentaacetic acid (DTPA) and o-phenylenediamine are mixed in a material ratio of 1:5, milled and mixed evenly, then put into a converter, and thermally condensed at 200°C for 24 hours until no water vapor is released. After the condensation product was cooled to 50°C, it was put into an equal mass of absolute ethanol to stir and stand still, filtered to obtain the crude product, washed with distilled water, ethanol and ether, and dried at low temperature to obtain a white powder, which was Ligand 6A, and the conversion rate was 72 %. The structure of Ligand 6A is:

[0039] Among them, R is

[0040] HRMS(ESI+)m / z calculated for C 44 h 44 N 13 (M+H):754.3843, found754.3845.

[0041] Ligand 6A and MnCl 2 4H 2 O was mixed according to the ratio of the amount of substances at 1:1, added to ethylene glycol with 2 times the mass, stirred and reacted at 60°C for 4 hours, cooled, filtered, and dried to obtain solid powder and transparent clear night. ...

Embodiment 3

[0043]Ethylenediaminetetraacetic acid (EDTA) and o-phenylenediamine are mixed at a material ratio of 1:4, milled and mixed evenly, then put into a converter, and co-heated and condensed at 180°C for 16 hours until no water vapor is released. After the condensation product was cooled to 50°C, it was put into an equal mass of absolute ethanol to stir and stand still, filtered to obtain the crude product, washed with distilled water, ethanol and ether, and dried at low temperature to obtain a white powder, which was Ligand 1A, and the conversion rate was 69 %. The structural formula of Ligand 1A is:

[0044] Among them, R is

[0045] HRMS(ESI+)m / z calculated for C 34 h 33 N 10 (M+H):581.2890, found581.2891.

[0046] Ligand 1A and CuSO 4 4H 2 O was mixed according to the mass ratio of 1:1.1, added to 2 times the mass of DMF, stirred and reacted at 60°C for 4 hours, cooled, filtered, and dried to obtain solid powder and transparent clear night. Solid powder was the fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com