Plasma incinerating and melting system for disposing furnace ash and furnace slag and method for disposing furnace ash and furnace slag by use of plasma incinerating and melting system

A melting system and plasma technology, applied in the direction of combustion methods, incinerators, combustion types, etc., can solve problems such as patent publications that have not yet been found, and achieve the effects of ultra-low leaching toxicity, resource saving, and easy availability of equipment and materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

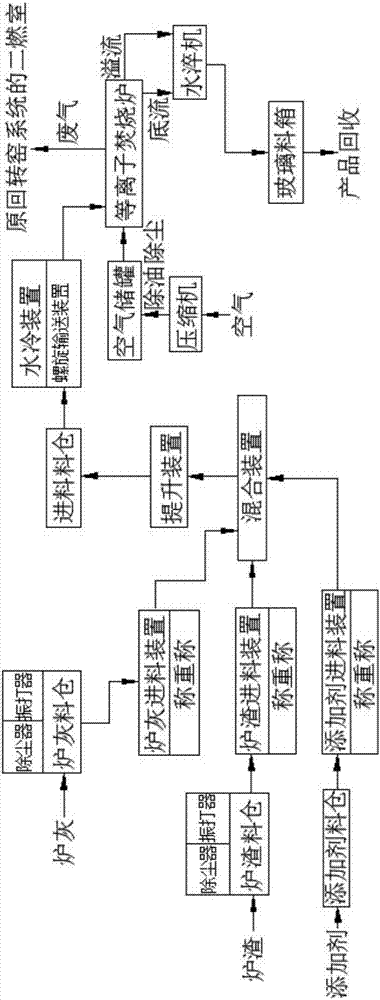

[0096] A method for processing furnace ash and slag using the above-mentioned plasma incineration and melting system for processing furnace ash and slag, the steps are as follows:

[0097] ⑴ Place the above-mentioned plasma incineration and melting system for processing furnace ash and slag at the tail of the original rotary kiln system, so that the feed end of the slag bin is connected to the slag discharge point at the tail of the original rotary kiln system, and the processed The slag is collected into the slag silo through the dust collector;

[0098] ⑵Convey the ash collected by the dust collector to the ash silo through the screw feeder;

[0099] (3) Put the additives in the additive silo, and then transport the materials in the slag silo, ash silo, and additive silo to the mixing device through the slag feeding device, furnace ash feeding device, and additive feeding device in turn. , mixed by a mixing device;

[0100] Among them, the amount of furnace ash added is no...

Embodiment 2

[0110] A method for processing furnace ash and slag using the plasma incineration and melting system for processing furnace ash and slag as described above, the steps are as follows:

[0111] (1) The plasma incineration and melting system is located at the tail of the rotary kiln, where the slag is discharged. The slag processed by the rotary kiln is collected into the slag bin. The slag feeding device adopts the spiral feeding method. The feeding device is wear-resistant and anti-corrosion. The equipment is made of wear-resistant stainless steel. The feeding device is equipped with a weighing scale to measure the feeding dose.

[0112] (2) The dust collected by the electrostatic precipitator is conveyed to the dust bin through the screw feeder. The feeding device is wear-resistant and anti-corrosion. The main transmission equipment is made of wear-resistant stainless steel. The feeding device is equipped with a weighing scale to measure the amount of feed. The ash conveying ...

Embodiment 3

[0121] A method for processing furnace ash and slag using the plasma incineration and melting system for processing furnace ash and slag as described above, the steps are the same as those in Example 1 unless otherwise specified, and the differences are as follows:

[0122] (1) The plasma incineration and melting system is located at the tail of the rotary kiln, where the slag is discharged. The slag processed by the rotary kiln is collected into the slag bin. The slag feeding device adopts the vibration feeding method. The feeding device is wear-resistant and anti-corrosion. The equipment is made of wear-resistant stainless steel. The feeding device is equipped with a weighing scale to measure the feeding dose.

[0123] (2) The dust collected by the electrostatic precipitator is conveyed to the dust bin through the screw feeder. The feeding device is wear-resistant and anti-corrosion. The main transmission equipment is made of wear-resistant stainless steel. The feeding devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com