Strong-effect filtering type centrifugal fan

A centrifugal fan and filtering technology, which is applied in the field of powerful filtering centrifugal fan, can solve the problems of environmental pollution, inability to filter the air twice, and failure to meet the use requirements of range hoods, etc., and achieve good filtering effect and stable overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

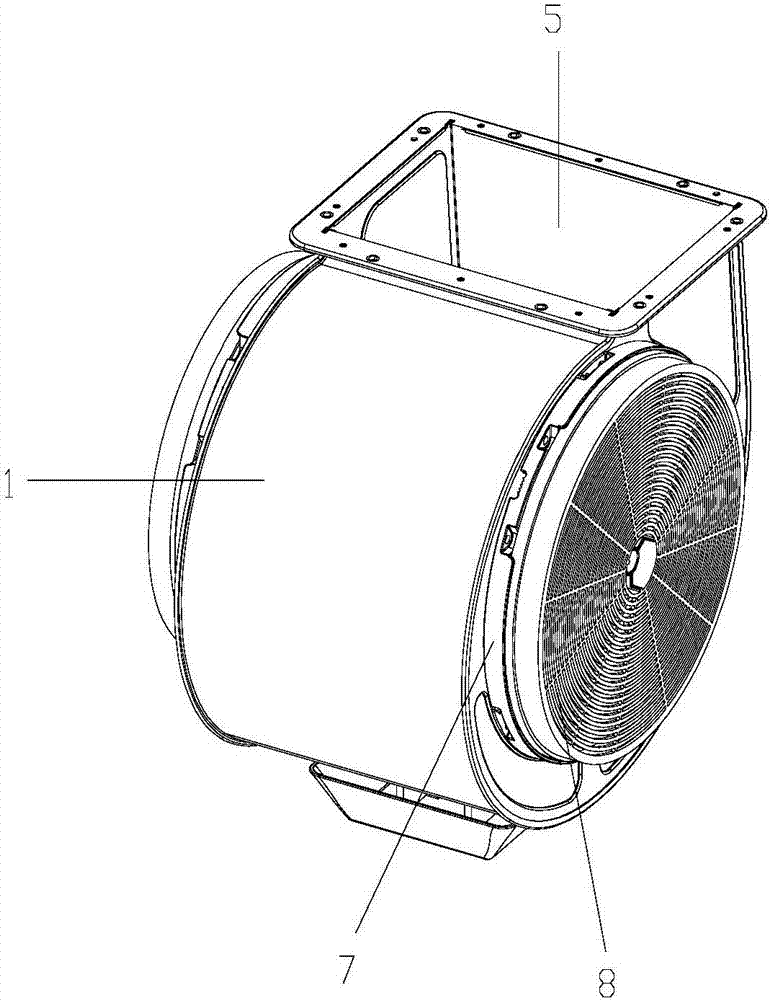

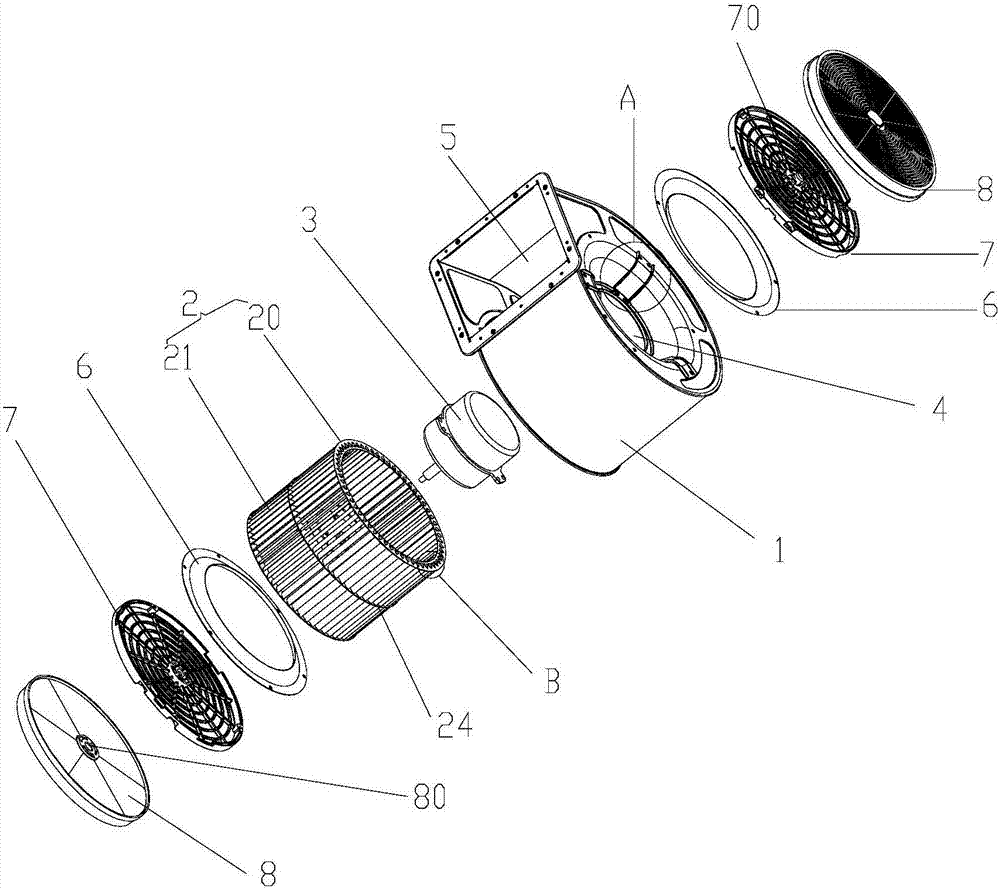

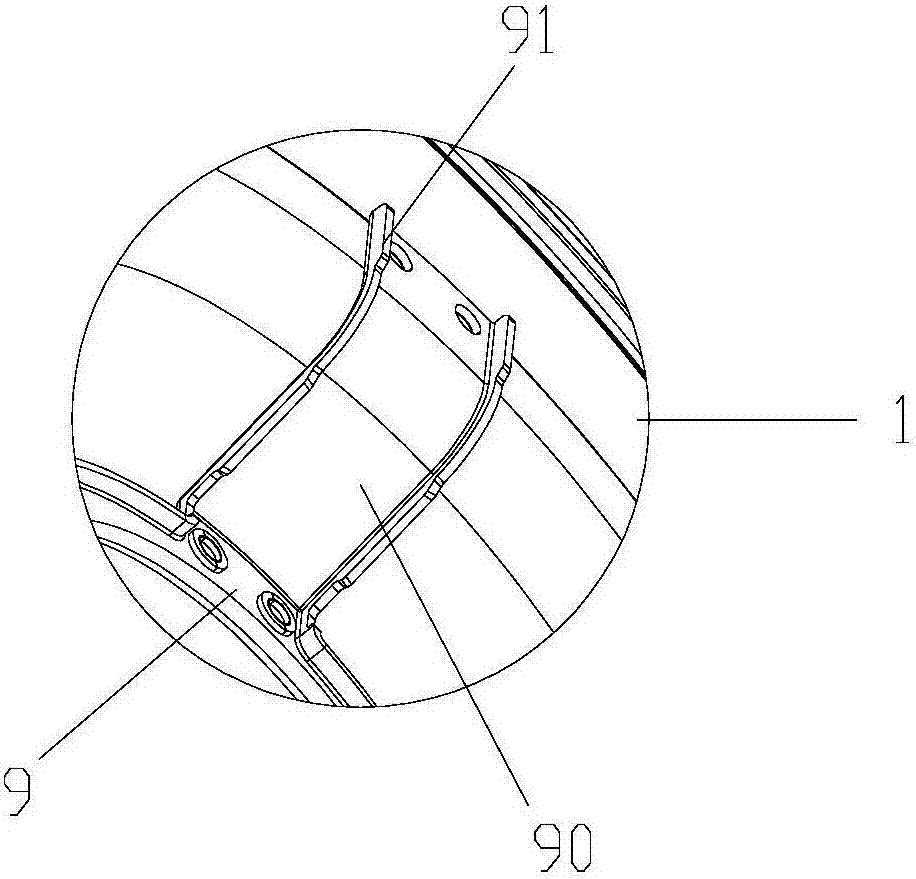

[0021] Such as figure 1 and figure 2 A powerful filtering centrifugal fan shown includes a volute 1, an impeller assembly 2 and a motor 3, the volute is provided with an air inlet chamber 4, an air duct 5 whose inner end communicates with the air inlet chamber, and the two impeller assemblies Each end is equipped with a wind guide cover 6, such as Figure 8 As shown, the air duct 5 is spirally distributed in the volute, the axial width of the air duct is equal everywhere, and the radial width of the air duct increases sequentially from the air inlet end to the air outlet end; image 3 As shown, the inner wall of the air inlet cavity is provided with a motor positioning ring 9, and three connecting bars 90 are arranged on both sides of the motor positioning ring, and the outer ends of the connecting bars are connected with the outer ends of the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com