Method for realizing gob-side entry retaining through grouting anchor cable

A technology for grouting anchor cables and empty entry retaining, which is applied in the directions of earthwork drilling, bolt installation, mining equipment, etc., can solve the problems of inability to achieve the effect of cemented roof, high support costs, failure of constant resistance anchor cables, etc. The effect of expanding the effective bearing range, improving the integrity and bearing capacity, and improving the strength and cohesion of the rock mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

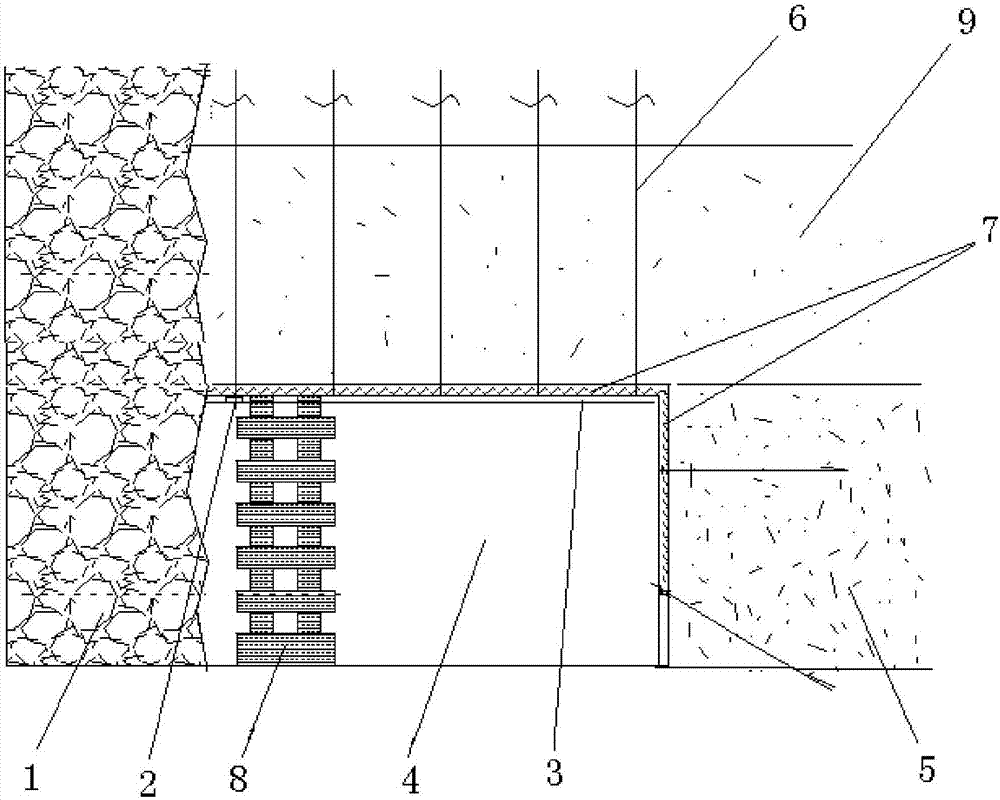

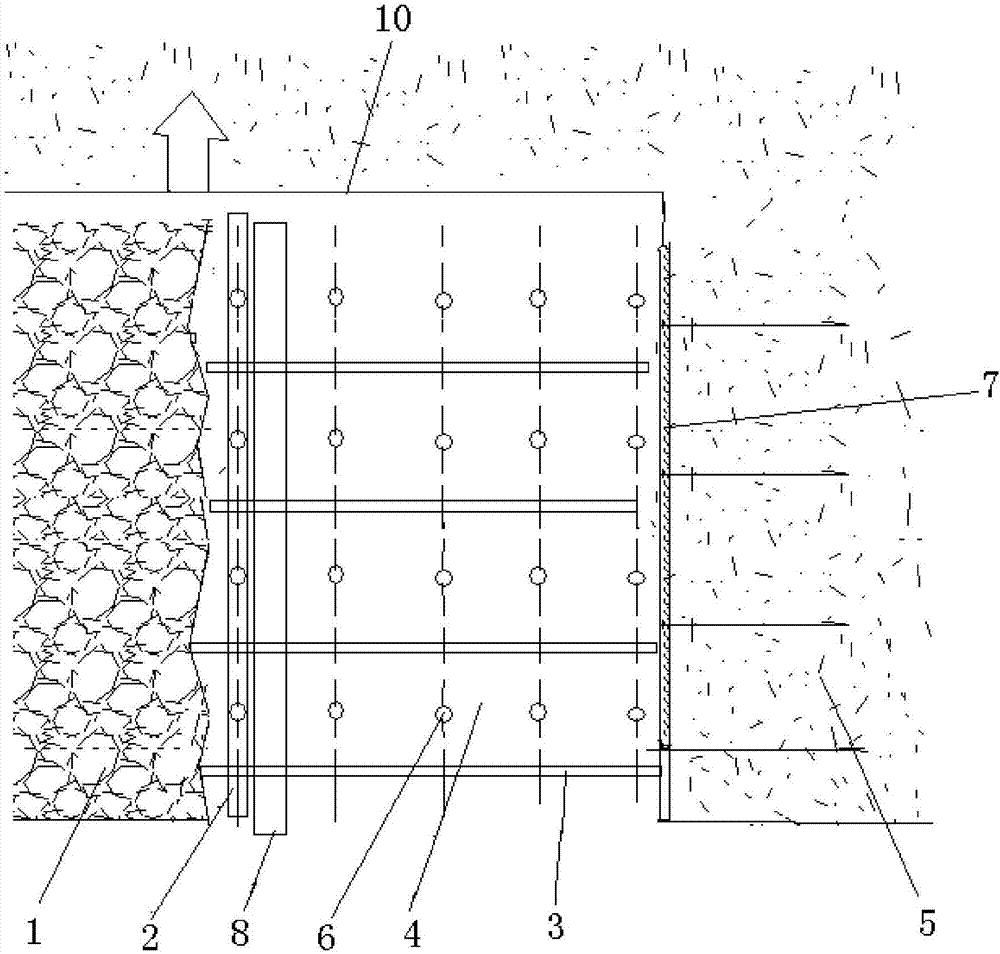

[0019] Such as figure 1 figure 2 As shown, a technical method of using grouting anchor cables to realize gob-side entry retention, the steps are:

[0020] In the first step, when the current coal mining face 10 is mined, the reserved roadway position of the next working face is designed and reserved on the side of the goaf 1, that is, the gob-side roadway 4 is reserved;

[0021] In the second step, while mining, four to six rows of anchor cable holes are constructed along the advancing direction on the top plate 9 of the reserved gob-side entry 4, the anchor cable hole spacing on each row is 80-120cm, and the anchor cable hole depth is greater than 6 m, the anchor hole on the far side is 10cm away from the boundary line of the roadway;

[0022] The third step is to install the grouting anchor cable 6 in the anchor cable hole while constructing the anchor cable hole. The roof of the goaf 4 is cemented into a whole; the row of anchor cables on the boundary line of the roadwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com