Underwater well repair assembly

An assembly and workover technology, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problems of high construction cost and high workover cost of special workover ships, and improve workover Efficiency, reduction of operational safety risks, and reduction of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

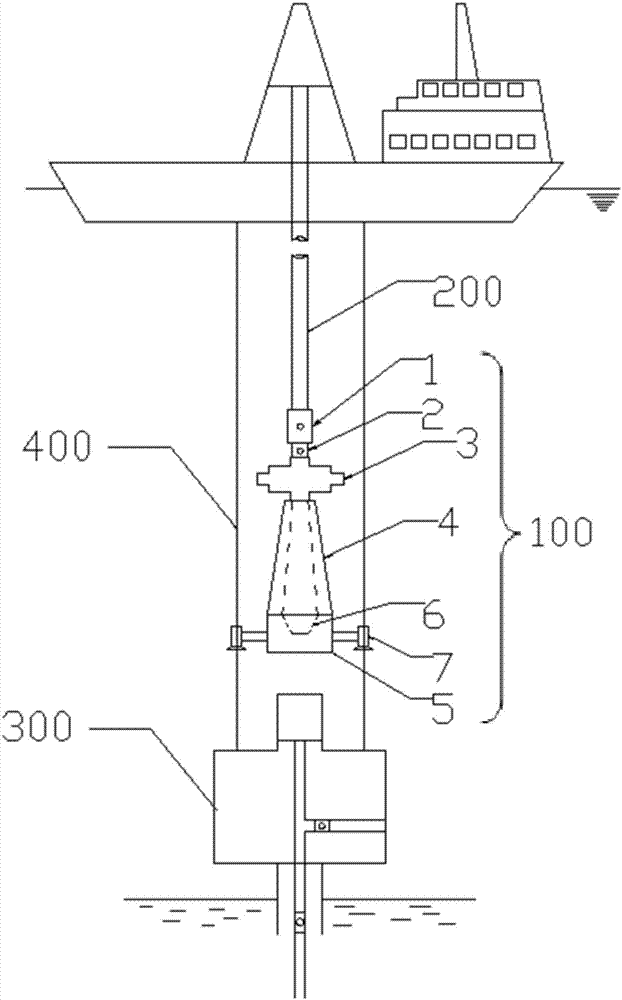

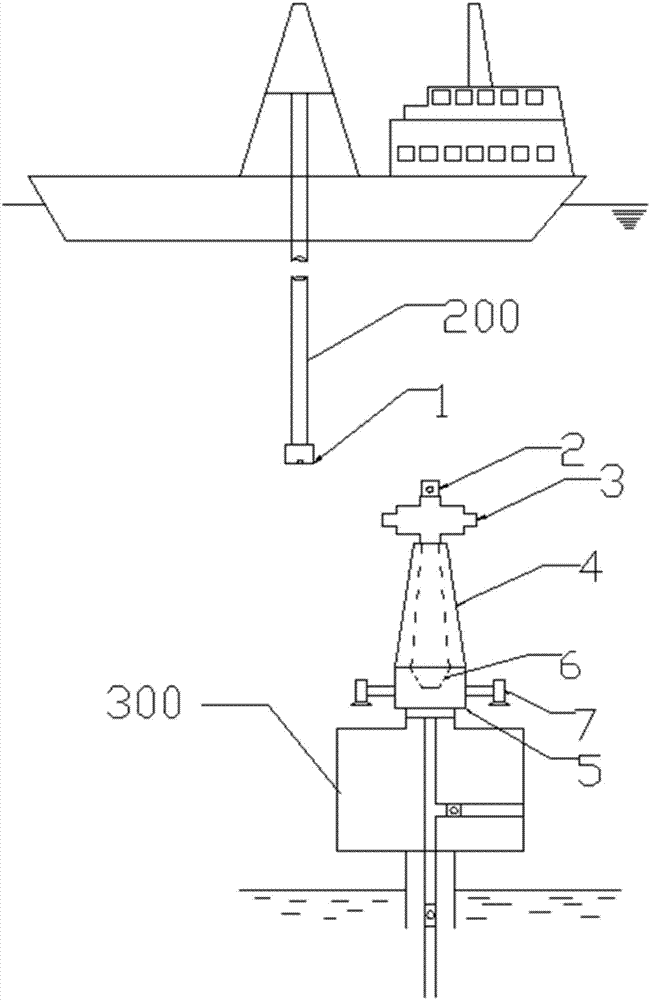

[0014] Such as figure 1 As shown, the present invention provides a subsea workover assembly 100, which includes a safety joint 1, a blowout preventer 2, a fully sealed shear ram blowout preventer 3, a stress joint 4 and Retractor 5, and the guide shorting 6 arranged inside the stress joint 4; the subsea workover assembly 100 is connected with the drill pipe 200 through the safety joint 1, and in an emergency, the safety joint 1 can be disconnected to make the drill pipe 200 is separated from the lower subsea workover assembly 100; the blowout preventer 2 is used to close the wellbore when there is no pipe string in the well; the fully sealed shear ram blowout preventer 3 is used to cut off the coiled tubing or steel wire in an emergency The working steel wire rope or other pipe strings used for well workover close the wellbore; the tieback 5 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com