Rose gold electroplating liquid, preparation method and electric casting method

An electroplating solution and rose gold technology, applied in the field of electroplating solution preparation, can solve the problems of poor corrosion resistance and affecting the use effect, etc., and achieve the effect of high brightness of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment discloses a rose gold electroplating solution, which includes 0.5-2g of copper sulfate, 100-125g of ammonium sulfite, 25-55g of disodium edetate, 85-115g of potassium citrate, palladium-containing 4-7g of palladium dichloride and 5-15g of sodium gold sulfite.

[0040] This electroplating solution can provide a kind of electroplating solution that is electroplated into rose gold on the jewelry surface, and the corrosion resistance of the electroplating solution is not good, and it can be used for a long time without fading.

[0041] 0.5g of copper sulfate, 100g of ammonium sulfite, 25g of disodium edetate, 85g of potassium citrate, 4g of palladium dichlorodiammine palladium and 5g of gold sodium sulfite. The surface of the coating is light rose gold, reaching mirror brightness, the hardness of the coating is high, the bonding force between the coating and the substrate is good, and the cathode current efficiency reaches 99%.

[0042] 1g of copper sulfate...

Embodiment 2

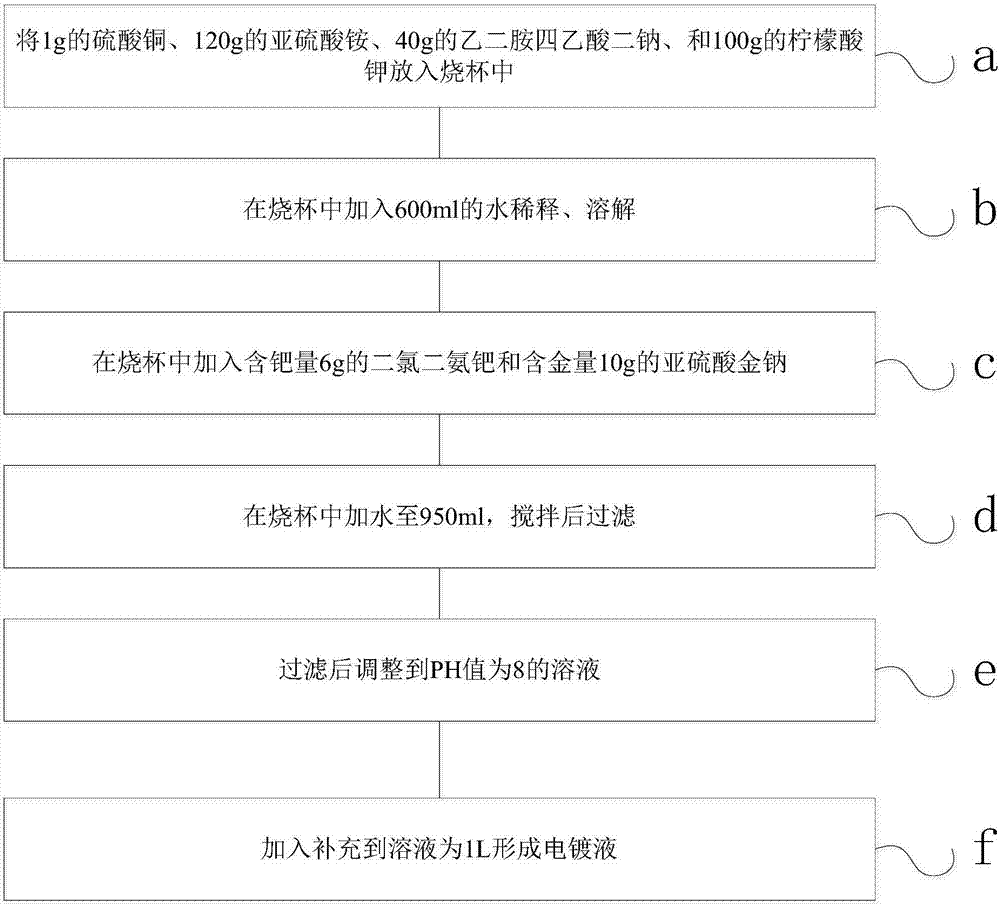

[0046] like figure 1 Shown, the invention discloses a kind of preparation method of rose gold electroplating solution, comprises the steps:

[0047] a, the copper sulfate of 1g, the ammonium sulfite of 120g, the disodium edetate of 40g, and the potassium citrate of 100g are put into beaker;

[0048] b. Add 600ml of water into the beaker to dilute and dissolve;

[0049] C, in beaker, add the dichlorodiammine palladium containing palladium amount 6g and the gold sodium sulfite of gold content 10g;

[0050] d. Add water to 950ml in the beaker, stir and filter;

[0051] e, after filtering, adjust to a solution with a pH value of 8;

[0052] f. Add supplement to the solution to 1L to form an electroplating solution.

[0053] The preparation method of the electroplating solution can provide a kind of electroplating solution that is electroplated into rose gold on the surface of jewelry. The electroplating solution produced by the invention has good corrosion resistance and can b...

Embodiment 3

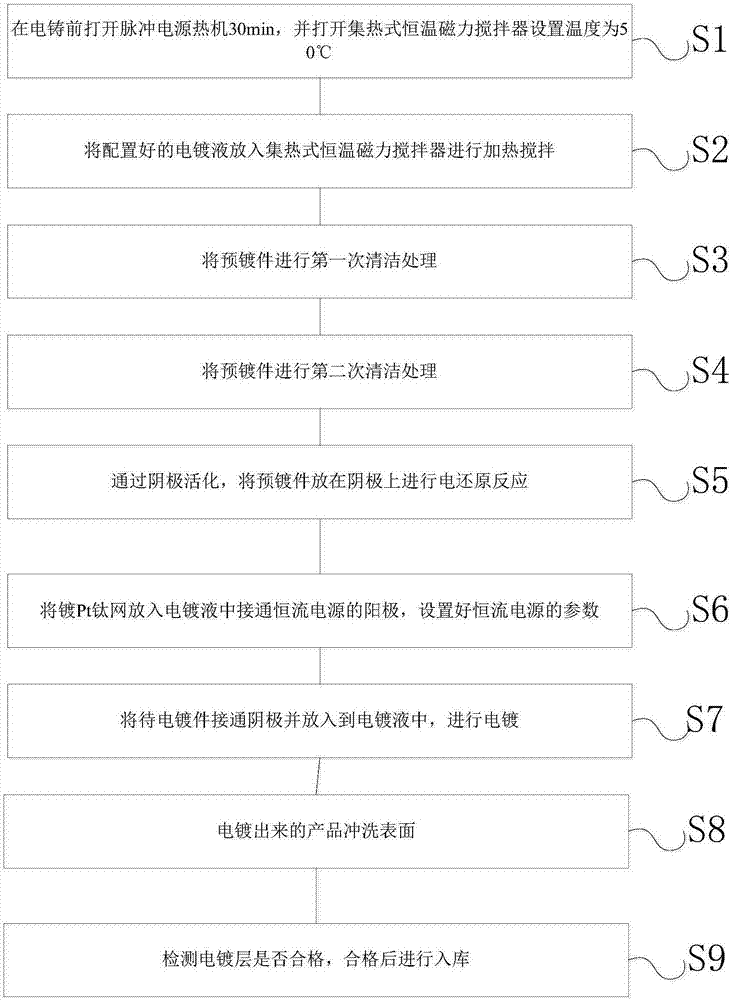

[0061] Such as figure 2 Shown, the present invention discloses a kind of electroplating method of rose gold electroplating solution, comprises the steps:

[0062] S1. Turn on the pulse power supply heat engine for 30 minutes before electroplating, and turn on the heat-collecting constant temperature magnetic stirrer and set the temperature to 50°C;

[0063] S2, putting the prepared electroplating solution into a heat-collecting constant temperature magnetic stirrer for heating and stirring;

[0064] S3, performing the first cleaning treatment on the pre-plated parts;

[0065] S4, performing a second cleaning treatment on the pre-plated parts;

[0066] S5, through cathode activation, place the pre-plated part on the cathode for electroreduction reaction;

[0067] S6, put the Pt-plated titanium mesh into the electroplating solution and connect the anode of the constant current power supply, and set the parameters of the constant current power supply;

[0068] S7, connect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com