Pearlescent pigment applied as car spray paint and preparation method thereof

A technology of pearlescent pigments and coatings, applied in the field of pearlescent pigments, which can solve the problems of weak interference effect, high price, and many steps, and achieve the effects of good brightness and color saturation, improved brightness and chroma, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

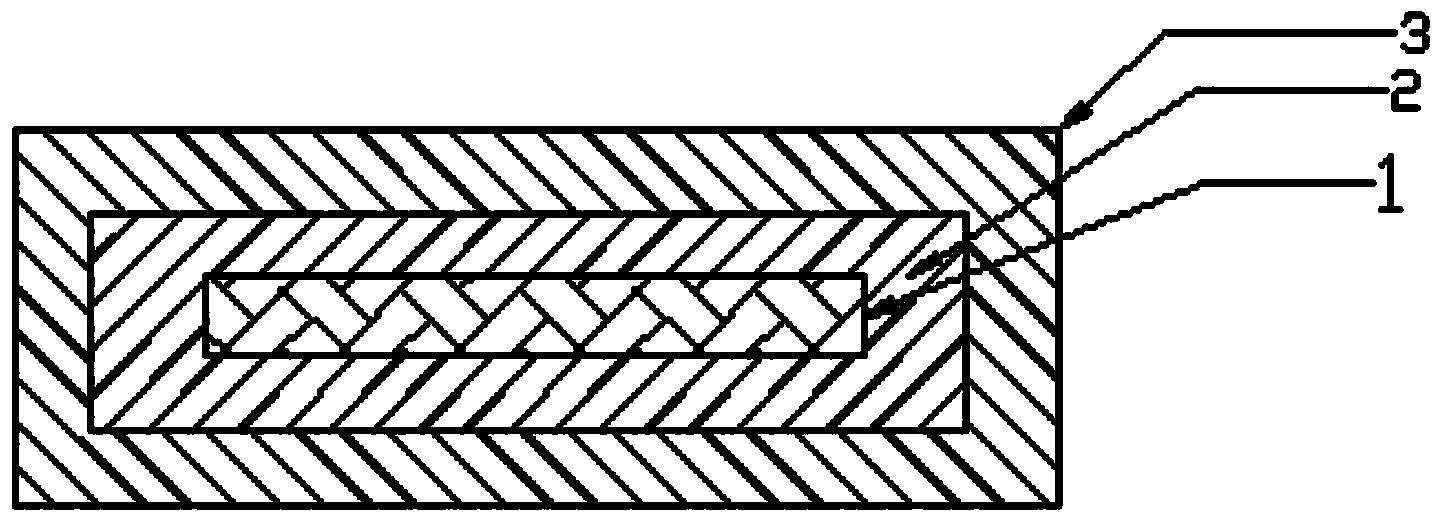

[0013] Example: This embodiment provides a pearlescent pigment and preparation method for car spray paint, which includes rutile TiO 2 The coated pearlescent pigment 1 is coated with a layer of titanium dioxide film 2, and the titanium dioxide film is coated with a layer of coloring agent 3 to form a metal oxide composite coating layer.

[0014] The coloring agent is ferric oxide or other metal oxides.

[0015] Rutile TiO 2 The coated pearlescent pigment uses granular mica as the base material. Firstly, deionized water is used to make a mica suspension. Under the condition of controlling the pH value, a Ticl4 solution with a concentration of 20-25% is added, and the reaction is carried out by stirring and heating at 80°C. , After filtration, washing, drying and calcination at 700 ° C, and then surface modification treatment in the system.

[0016] In the specific implementation process, at a temperature of 70°C-80°C, the stirring of the substrate suspension is kept, the pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com