Preparation method of water-soluble blue-violet light carbon quantum dots

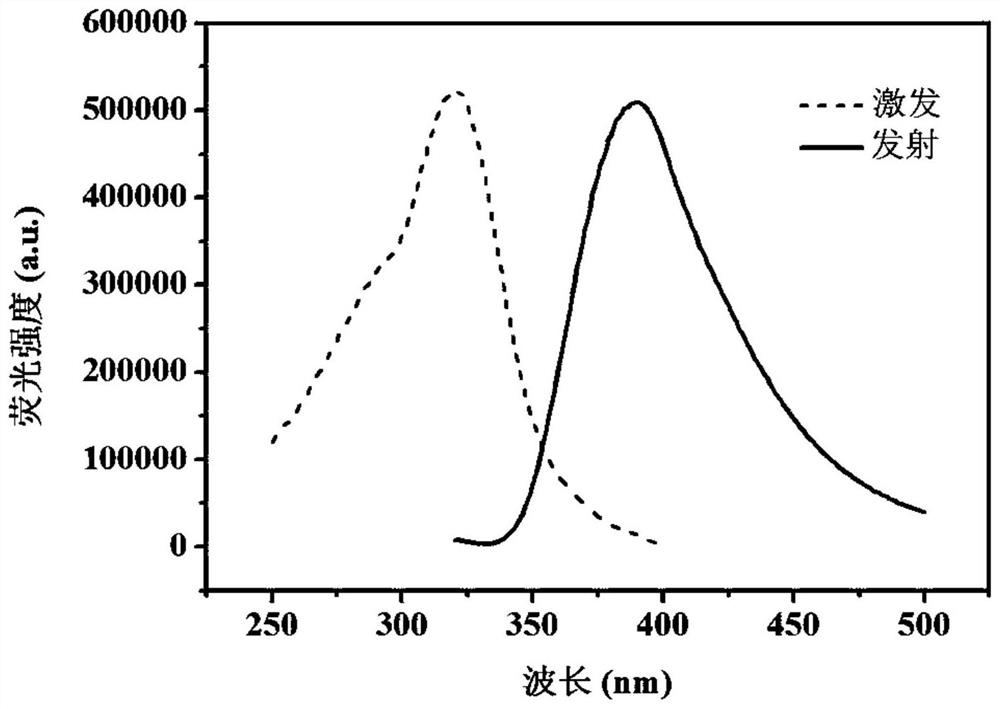

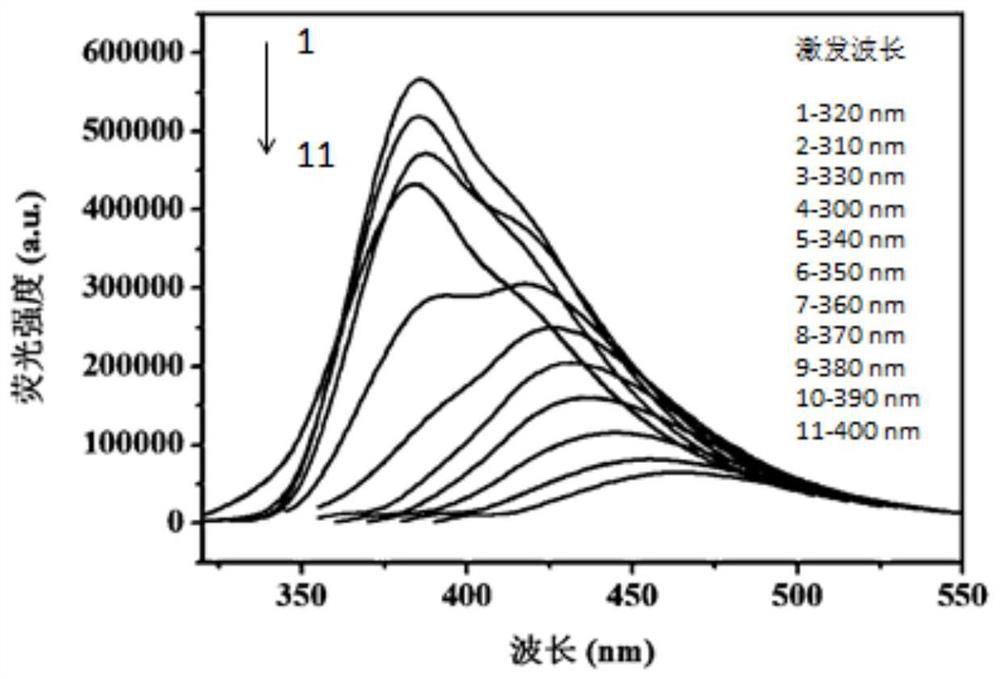

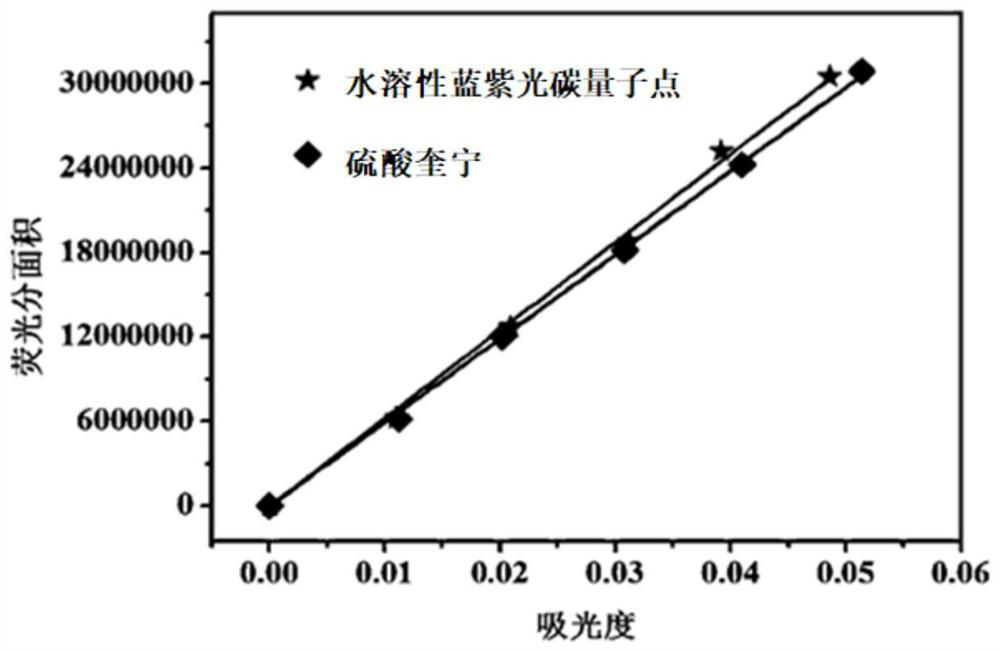

A carbon quantum dot, water-soluble technology, applied in the direction of biochemical equipment and methods, chemical instruments and methods, hydrolytic enzymes, etc., can solve the unfavorable continuous and large-scale production of fluorescent carbon quantum dots, low carbon quantum yield, non-renewable energy and other problems, to achieve the effect of shortening the activation time, stable fluorescence, and rich carbon source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of water-soluble blue-violet light carbon quantum dots, comprising the following steps:

[0031] S1. Mix pancreatin, ethylenediamine, and ultrapure water with a mass volume ratio of 1.5g:1mL:9mL to obtain a mixed solution, and the mixed solution is subjected to hydrothermal reaction to obtain a reaction solution; wherein, the mixed solution in step S1 Including 1.5g of trypsin, 1mL of ethylenediamine, and 9mL of ultrapure water. The hydrothermal reaction is as follows: put the mixed solution in a 25ml reactor and stir for 5 minutes. The reaction temperature is controlled at 170-190°C. The time is 9.5~10.5h, and the reaction liquid is obtained, wherein, the reaction liquid is dark brown;

[0032] S2. Take the reaction solution and go through centrifugation, filtration, dialysis, and evaporation to prepare water-soluble blue-violet light carbon quantum dots. The centrifugation time is 20 minutes. After centrifuging the reaction solution, take the supe...

Embodiment 2

[0034] A preparation method of water-soluble blue-violet light carbon quantum dots, comprising the following steps:

[0035] S1. Mix pancreatin, ethylenediamine, and ultrapure water with a mass volume ratio of 1.5g:1mL:9mL to obtain a mixed solution, and the mixed solution is subjected to hydrothermal reaction to obtain a reaction solution; wherein, the mixed solution in step S1 Including 1.5g of trypsin, 1mL of ethylenediamine, and 9mL of ultrapure water, the hydrothermal reaction is as follows: put the mixed solution in a 25ml reactor and stir for 5min, control the reaction temperature at 180°C, and the reaction time is 10h, obtained reaction solution, wherein, reaction solution is dark brown;

[0036] S2. Take the reaction solution and go through centrifugation, filtration, dialysis, and evaporation to prepare water-soluble blue-violet light carbon quantum dots. The centrifugation time is 20 minutes. After centrifuging the reaction solution, take the supernatant and use mic...

Embodiment 3

[0038] A preparation method of water-soluble blue-violet light carbon quantum dots, comprising the following steps:

[0039] S1. Mix pancreatin, ethylenediamine, and ultrapure water with a mass volume ratio of 1.5g:1mL:9mL to obtain a mixed solution, and the mixed solution is subjected to hydrothermal reaction to obtain a reaction solution; wherein, the mixed solution in step S1 Including 1.5g of trypsin, 1mL of ethylenediamine, and 9mL of ultrapure water, the hydrothermal reaction is as follows: put the mixed solution in a 25ml reactor and stir for 5min, control the reaction temperature at 190°C, and the reaction time is 10.5h, obtained reaction solution, wherein, reaction solution is dark brown;

[0040] S2. Take the reaction solution and go through centrifugation, filtration, dialysis, and evaporation to prepare water-soluble blue-violet light carbon quantum dots. The centrifugation time is 20 minutes. After centrifuging the reaction solution, take the supernatant and use m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com