Method for preparing high-performance fluorine-silicon modified finish-coat paint

A technology of fluorosilicon modification and finishing paint, which is applied to biocide-containing paints, coatings, antifouling/underwater coatings, etc., which can solve the problem of poor performance of weather resistance, color retention, stain and stain resistance additives and complicated preparation process , pollute the environment and other issues, and achieve good dispersion, uniform surface properties, and good film-forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

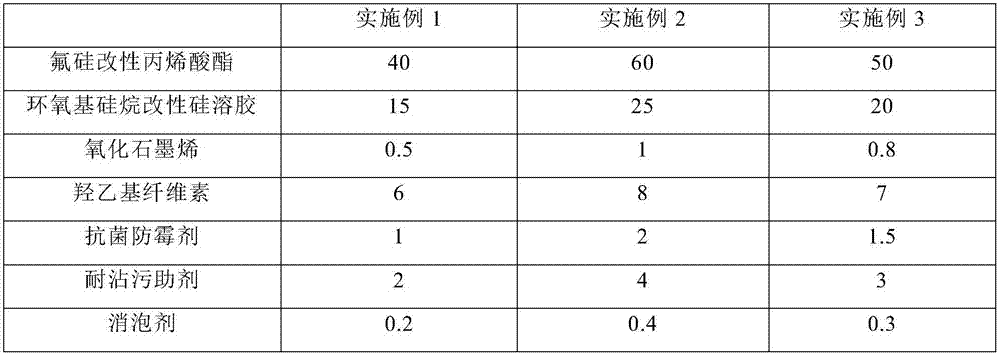

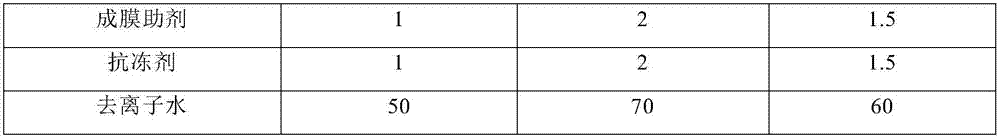

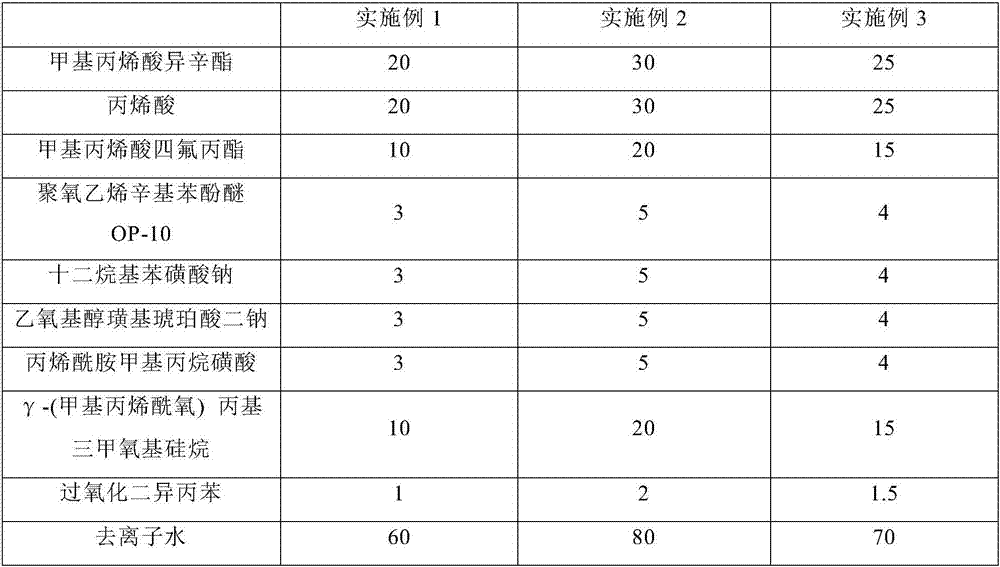

Embodiment 1

[0038] A preparation method for a high-performance fluorosilicon modified finish paint, comprising the following steps:

[0039] (1) Fluorosilicone modified acrylate preparation: isooctyl methacrylate, acrylic acid, tetrafluoropropyl methacrylate, polyoxyethylene octylphenol ether OP-10, sodium dodecylbenzenesulfonate and After the ionic water is mixed evenly, add dicumyl peroxide, heat up to 80°C, keep warm for 8 minutes, then add disodium ethoxylated alcohol sulfosuccinate and sodium acrylamidomethyl propane sulfonate, mix evenly, cool down to 30°C, Then add ammonia water to adjust the pH of the system to 7, filter and cool to room temperature to obtain material A; add material A and γ-(methacryloyloxy)propyltrimethoxysilane to deionized water, add N,N dimethylethanolamine to adjust The pH of the system was raised to 8, the temperature was raised to 60°C, the material was aged after stirring for 40 minutes to obtain fluorosilicon-modified acrylate;

[0040] (2) Preparation ...

Embodiment 2

[0053] A preparation method for a high-performance fluorosilicon modified finish paint, comprising the following steps:

[0054] (1) Fluorosilicone modified acrylate preparation: isooctyl methacrylate, acrylic acid, tetrafluoropropyl methacrylate, polyoxyethylene octylphenol ether OP-10, sodium dodecylbenzenesulfonate and After the ionic water is mixed evenly, add dicumyl peroxide, heat up to 90°C, keep warm for 12 minutes, then add disodium ethoxylated alcohol sulfosuccinate and sodium acrylamidomethyl propane sulfonate, mix evenly, cool down to 40°C, Then add ammonia water to adjust the pH of the system to 8, filter and cool to room temperature to obtain material A; add material A and γ-(methacryloyloxy)propyltrimethoxysilane to deionized water, add N,N dimethylethanolamine to adjust The pH of the system was raised to 10, the temperature was raised to 70°C, stirred for 80 minutes and aged to obtain fluorosilicon-modified acrylate;

Embodiment 3

[0068] A preparation method for a high-performance fluorosilicon modified finish paint, comprising the following steps:

[0069] (1) Fluorosilicone modified acrylate preparation: isooctyl methacrylate, acrylic acid, tetrafluoropropyl methacrylate, polyoxyethylene octylphenol ether OP-10, sodium dodecylbenzenesulfonate and After the ionic water is mixed evenly, add dicumyl peroxide, heat up to 85°C, keep warm for 10 minutes, then add disodium ethoxylated alcohol sulfosuccinate and sodium acrylamidomethyl propane sulfonate, mix evenly, cool down to 35°C, Then add ammonia water to adjust the pH of the system to 7.5, filter and cool to room temperature to obtain material A; add material A and γ-(methacryloyloxy)propyltrimethoxysilane to deionized water, add N,N dimethylethanolamine to adjust The pH of the system was raised to 9, and the temperature was raised to 65°C, stirred for 60 minutes and aged to obtain fluorosilicon-modified acrylate;

[0070] (2) Preparation of epoxy sila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com