A kind of modified diatomite water-based environmental protection paint and preparation method thereof

A technology of environmentally friendly paint and diatomite, applied in coatings and other directions, can solve the problems of formaldehyde escape, secondary pollution of the human body, and non-permanent adsorption, and achieve the effects of avoiding resource waste, protecting the environment, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

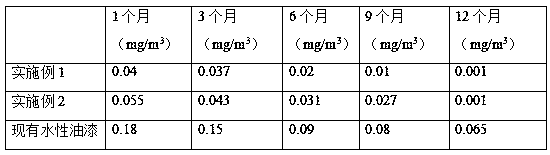

Examples

Embodiment 1

[0026] A modified diatomite water-based environmental protection paint is characterized in that it comprises the following components by weight: 13 parts of acrylate emulsion; 7 parts of water-based polyurethane synthetic resin; 1.5 parts of dipropylene glycol butyl ether; 17 parts of deionized water; 0.35 parts of polyethylene glycol esters; 9 parts of polyacrylates; 0.2 parts of polyoxypropylene glyceryl ether; 0.5 parts of dioctyl sodium sulfosuccinate; 0.15 parts of zinc oxide; 11 parts of white pulp; 25 parts of modified diatomaceous earth; 0.6 parts of water-based silane coupling agent.

[0027] Modified diatomite adopts the following preparation method:

[0028] 1) Weigh 500 g of diatomite raw soil and put it into a 2L beaker, slowly add 500 mL of 4 mol. L -1 Hydrochloric acid solution, after the dropwise addition, put it into a water bath at 80°C and soak for 2 hours, filter and wash with suction; then add 500mL4mol. L -1 Potassium hydroxide solution, soaked for 5 ...

Embodiment 2

[0038]A modified diatomite water-based environmental protection paint is characterized in that it comprises the following components by weight: 10 parts of acrylate emulsion; 6 parts of water-based polyurethane synthetic resin; 1 part of dipropylene glycol butyl ether; 16 parts of deionized water; fatty acid 0.2 part of polyethylene glycol ester; 8 parts of associative polyurethane; 0.1 part of polyoxyethylene polyoxypropylene glyceryl ether; 0.3 part of diisooctyl sodium sulfosuccinate; 0.1 part of zinc oxide; 0.1 part of alkane; 7 parts of titanium white paste; 20 parts of modified diatomaceous earth; 0.5 part of water-based silane coupling agent.

[0039] Modified diatomite adopts the following preparation method:

[0040] 1) Weigh 500 g of diatomite raw soil and put it into a 2L beaker, slowly add 500 mL of 4 mol. L -1 Hydrochloric acid solution, after the dropwise addition, put it into a water bath at 80°C and soak for 2 hours, filter and wash with suction; then add 500...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com