Non-toxic plasticine

A plasticine and modified technology, applied in the field of children's toys, can solve problems such as skin damage, allergic phenomena, and adverse development of children's respiratory system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

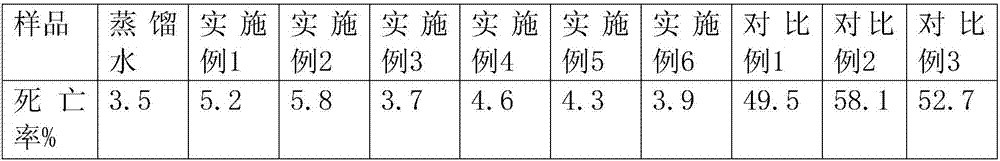

Examples

Embodiment 1

[0027] A kind of nontoxic plasticine, comprises following weight component:

[0028] 7 parts of modified starch, 4 parts of modified glutinous rice glue, 2 parts of bone glue, 1 part of kaolin, 0.5 parts of hyaluronic acid, 0.3 parts of lemon yellow, 0.1 part of sodium diacetate, 0.2 parts of potassium hydrogen tartrate, 0.7 parts of aloe vera gel, 0.1 part of tung oil, 0.1 part of turpentine oil, 0.1 part of castor oil, 3 parts of microcrystalline wax, 0.05 part of preservative, and 2 parts of water.

[0029] The preservative is a 20% aqueous solution compounded with a bactericide and an antioxidant at a ratio of 5:1, the bactericide is oregano oil, and the antioxidant is sage extract.

[0030] The specific preparation steps of the modified starch are as follows:

[0031] (1) Take 20g of tapioca starch, add 35g of citric acid-sodium citrate buffer solution with a concentration of 0.05mol / L and a pH value of 3.5, heat up to 40°C, and stir evenly;

[0032] (2) Add 0.2 g of gl...

Embodiment 2

[0042] A kind of nontoxic plasticine, comprises following weight component:

[0043] 8 parts of modified starch, 7 parts of modified glutinous rice glue, 3 parts of bone glue, 2 parts of kaolin, 0.9 parts of propylene glycol, 0.5 parts of capsanthin, 0.3 parts of potassium hydrogen tartrate, 1.5 parts of aloe gel, 0.2 parts of tung oil, 0.5 parts of turpentine oil , 0.2 parts of castor oil, 4 parts of microcrystalline wax, 0.15 parts of preservative, and 3 parts of water.

[0044] The preservative is a 20% aqueous solution compounded with a bactericide and an antioxidant at a ratio of 5:1, the bactericide is oregano oil, and the antioxidant is licorice extract.

[0045] The specific preparation steps of the modified starch are as follows:

[0046] (1) Take 23g of potato starch, add 38g of citric acid-sodium citrate buffer solution with a concentration of 0.06mol / L and a pH value of 3.5, heat up to 42°C, and stir evenly;

[0047] (2) Add 0.3 g of glucoamylase, and stir at 42°...

Embodiment 3

[0057] A kind of nontoxic plasticine, comprises following weight component:

[0058] 8 parts of modified starch, 5 parts of modified glutinous rice glue, 3 parts of bone glue, 2 parts of kaolin, 0.6 part of sorbitol, 0.5 part of sunset yellow, 0.3 part of sodium diacetate, 0.3 part of potassium hydrogen tartrate, 0.9 part of aloe vera gel, tung oil 0.3 parts, turpentine oil 0.4 parts, castor oil 0.4 parts, microcrystalline wax 5 parts, preservative 0.08 parts, water 3 parts.

[0059] The preservative is a 20% aqueous solution compounded with a bactericide and an antioxidant at a ratio of 6:1, the bactericide is oregano oil, and the antioxidant is licorice extract.

[0060] The specific preparation steps of the modified starch are as follows:

[0061] (1) Take 25g of wheat starch, add 40g of citric acid-sodium citrate buffer solution with a concentration of 0.07mol / L and a pH value of 3.7, heat up to 45°C, and stir evenly;

[0062] (2) Add 0.4 g of glucoamylase, and stir the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com