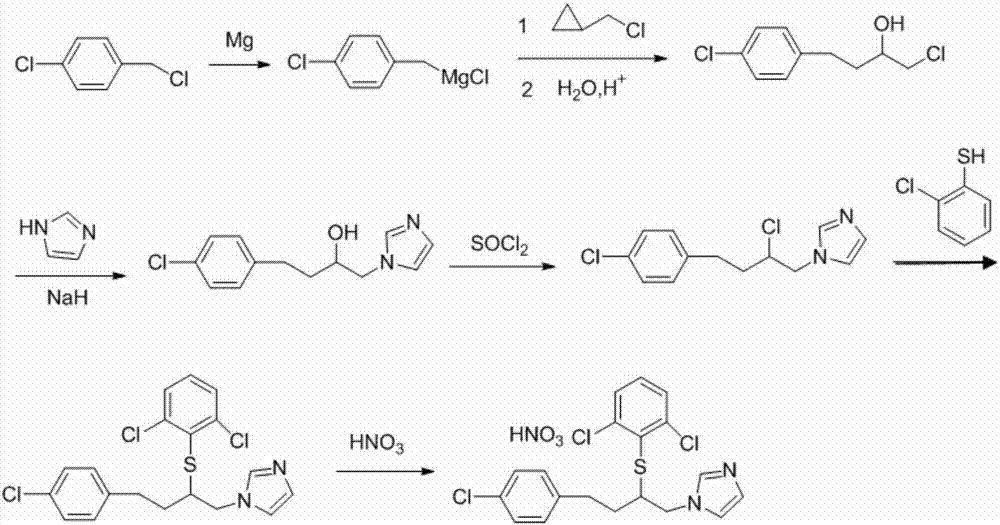

Preparation method of butoconazole nitrate

A technology of butoconazole nitrate and imidazole, which is applied in the field of preparation of butoconazole nitrate, can solve the problems of complex preparation method, low product purity, and low recovery rate of butoconazole nitrate, and achieve low cost, high product purity and simple steps simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of butoconazole nitrate, which comprises the following steps:

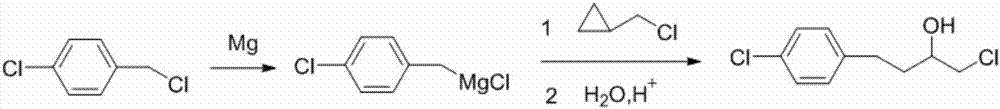

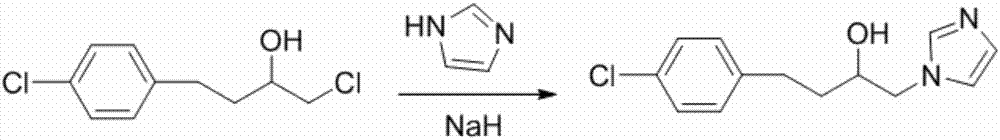

[0035] (1) Synthesis of 1-chloro-4-(4-chlorophenyl)-2-butanol, adding magnesium powder and anhydrous ether in the reaction flask, the mass ratio of magnesium powder and anhydrous ether is 12:142.7, Then add 4-chlorobenzyl chloride and anhydrous ether in the dropping funnel to obtain a mixed solution, the mass ratio of magnesium powder to 4-chlorobenzyl chloride and anhydrous ether in the mixed solution is 12:80:114.1, and add to the reaction flask Add the mixed solution in the reaction bottle, the volume ratio of the added mixed solution to the anhydrous ether in the reaction bottle is 2.5:200, the surface gas of the magnesium powder is generated, the solution is turbid and there is ether reflux, start stirring, and slowly add the rest of the mixed solution dropwise, Control the rate of addition, keep the diethyl ether solution in a slightly boiling state, reflux for 18 minutes after th...

Embodiment 2

[0044] A preparation method of butoconazole nitrate, which comprises the following steps:

[0045] (1) Synthesis of 1-chloro-4-(4-chlorophenyl)-2-butanol, adding magnesium powder and anhydrous ether in the reaction flask, the mass ratio of magnesium powder and anhydrous ether is 12:142.7, Then add 4-chlorobenzyl chloride and anhydrous ether in the dropping funnel to obtain a mixed solution, the mass ratio of magnesium powder to 4-chlorobenzyl chloride and anhydrous ether in the mixed solution is 12:80:114.1, and add to the reaction flask Add the mixed solution in the reaction bottle, the volume ratio of the added mixed solution to the anhydrous ether in the reaction bottle is 2.7:200, the surface gas of the magnesium powder is generated, the solution is turbid and there is ether reflux, start stirring, and slowly add the rest of the mixed solution dropwise, Control the rate of addition, keep the diethyl ether solution in a slightly boiling state, reflux for 18 minutes after th...

Embodiment 3

[0054] A preparation method of butoconazole nitrate, which comprises the following steps:

[0055] (1) Synthesis of 1-chloro-4-(4-chlorophenyl)-2-butanol, adding magnesium powder and anhydrous ether in the reaction flask, the mass ratio of magnesium powder and anhydrous ether is 12:142.7, Then add 4-chlorobenzyl chloride and anhydrous ether in the dropping funnel to obtain a mixed solution, the mass ratio of magnesium powder to 4-chlorobenzyl chloride and anhydrous ether in the mixed solution is 12:80:114.1, and add to the reaction flask Add the mixed solution in the reaction bottle, the volume ratio of the added mixed solution to the anhydrous ether in the reaction bottle is 2.5:200, the surface gas of the magnesium powder is generated, the solution is turbid and there is ether reflux, start stirring, and slowly add the rest of the mixed solution dropwise, Control the rate of addition, keep the ether solution in a slightly boiling state, reflux for 16 minutes after the additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com