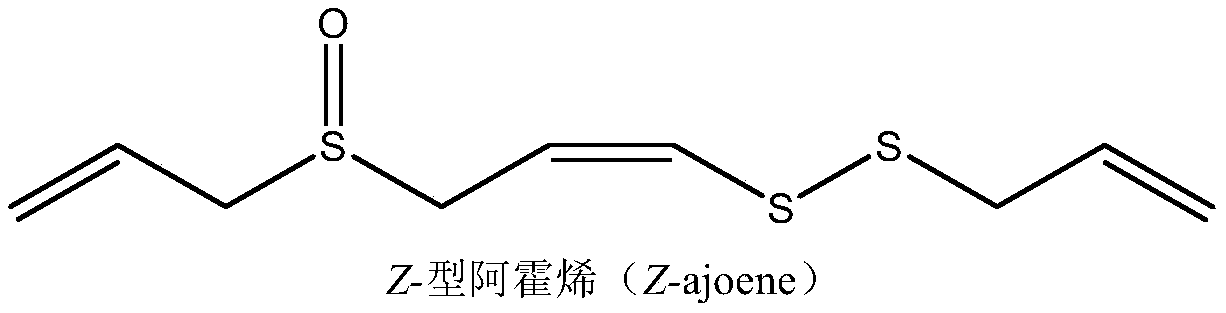

A method for molecular distillation separation and purification of ajoene in garlic extract

A technology of garlic extract and molecular distillation, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of difficult recovery rate of solvents, high safety requirements, long production cycle, etc., and achieve solvent-free Residue, low preparation cost, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Weigh 10kg of pretreated garlic, pulverize it to a particle size of 1mm, add 40L of 95% ethanol solution, extract by ultrasonic vibration at room temperature for 1.5h, filter after extraction, and concentrate the filtrate under reduced pressure at 55-70°C to remove the solvent to obtain garlic crude extract. Recovered ethanol is used for the next batch of extraction after being tested and meets the requirements, and garlic residue is used to extract polar components such as polysaccharides or to make feed;

[0027] (2) The garlic crude extract that step (1) obtains is joined in the feeding tank of molecular distillation device, is that 70 ℃, vacuum degree are carried out pre-degassing under the condition of 200Pa at temperature, after degassing, distill vacuum degree The distillation temperature is 100Pa, the distillation temperature is 100°C; the cooling temperature is 10°C; the feed rate is 5ml / min; the scraper speed is 280r / min, and the first-stage molecular dist...

Embodiment 2

[0030] (1) Weigh 10kg of pretreated garlic, pulverize it to a particle size of 0.2mm, add 20L of 95% ethanol solution, extract by ultrasonic vibration at room temperature for 2.5h, filter after the extraction is completed, and concentrate the filtrate under reduced pressure at 55-70°C to remove the solvent Obtain garlic crude extract. Recovered ethanol is used for the next batch of extraction after being tested and meets the requirements, and garlic residue is used to extract polar components such as polysaccharides or to make feed;

[0031](2) The garlic crude extract that step (1) obtains is joined in the feeding tank of molecular distillation device, is that 50 ℃, vacuum degree are carried out pre-degassing under the condition of 200Pa at temperature, after degassing, in distillation vacuum degree The distillation temperature is 50Pa, the distillation temperature is 120°C; the cooling temperature is 0°C; the feed rate is 10ml / min; the scraper speed is 400r / min to carry out ...

Embodiment 3

[0034] (1) Weigh 10 kg of pretreated garlic, pulverize it to a particle size of 2 mm, add 60 L of 95% ethanol solution, extract by ultrasonic vibration at room temperature for 1.0 h, filter after the extraction is completed, and concentrate the filtrate under reduced pressure at 55 to 70 ° C to remove the solvent to obtain Crude garlic extract. Recovered ethanol is used for the next batch of extraction after being tested and meets the requirements, and garlic residue is used to extract polar components such as polysaccharides or to make feed;

[0035] (2) Add the garlic crude extract obtained in step (1) into the feed tank of the molecular distillation device, and carry out pre-degassing at a temperature of 80° C. and a vacuum of 200 Pa. After degassing, the distillation vacuum The distillation temperature is 50Pa, the distillation temperature is 80°C; the cooling temperature is 20°C; the feed rate is 1ml / min; the scraper speed is 200r / min, and the first-stage molecular distil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com