Application of hydrated calcium silicate fiber to prepare aerated concrete blocks

A hydrated calcium silicate, aerated concrete technology, applied in the application, home appliances, ceramic products and other directions, can solve the problem that polypropylene fiber reduces the compressive strength of aerated concrete blocks and affects the strength stability of aerated concrete blocks , low addition of polypropylene fibers, etc., to achieve the effect of promoting technology development, promoting quality improvement and reducing consumption, and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] step 1):

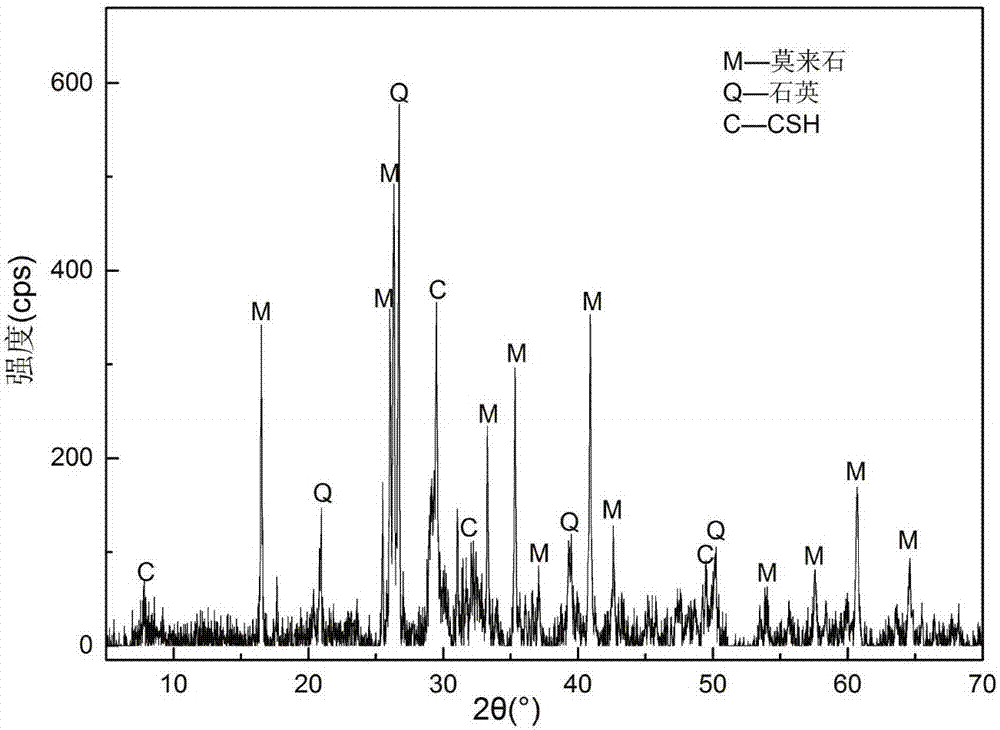

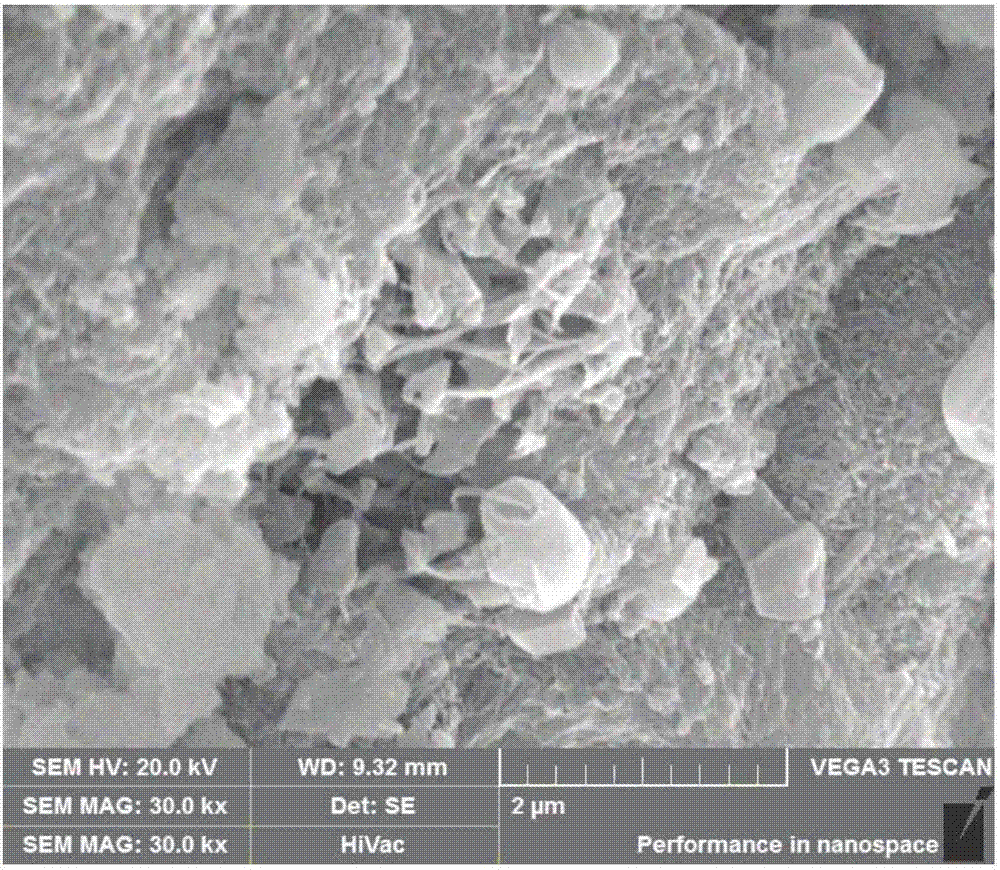

[0060] Be that 0.4 and liquid-solid ratio are 15mL / g preparation slurry according to calcium-silicon molar ratio, add the NaOH of 20g / L to adjust the pH value of slurry (pH is 13); Gained suspension slurry is put into pressure reactor, stir Raise the temperature to 160°C, and react at a constant temperature under 0.6MPa pressure for 2 hours; after the reaction, cool the slurry to room temperature, take out the slurry, and obtain the product (calcium silicate hydrate fiber additive) after solid-liquid separation, washing and drying . The obtained product was subjected to XRD and SEM analysis. The main mineral composition of the product is mullite, quartz and calcium silicate hydrate gel. The calcium silicate hydrate fiber has a diameter of 0.1-0.5 μm, a length of 1-5 μm, and an aspect ratio of 20-30; the calcium-silicon atomic ratio of the calcium silicate hydrate fiber is 0.75.

[0061] Step (2):

[0062] The pouring slurry content (in parts by weight) is...

Embodiment 2

[0065] step 1):

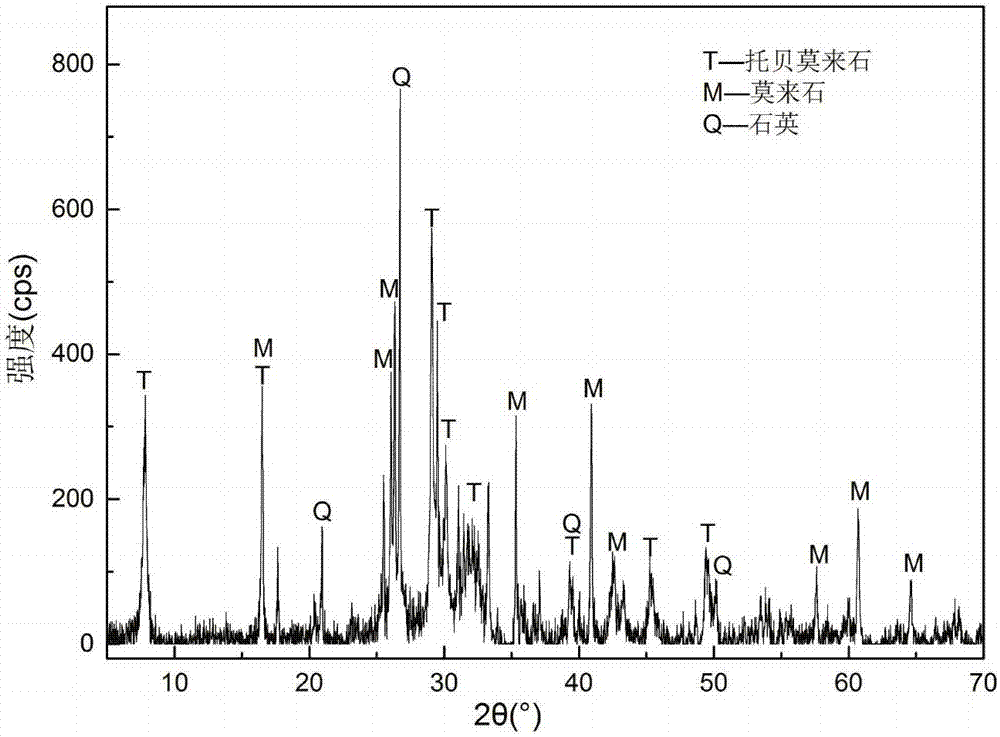

[0066] Be 0.8 and liquid-solid ratio according to calcium-silicon mole ratio be 25mL / g preparation slurry, add the NaOH of 10g / L to adjust the pH value of slurry (pH is 13); Gained suspension slurry is put into pressure reactor, stir Raise the temperature to 180°C, and react at a constant temperature under a pressure of 1.3MPa for 1.0h; after the reaction, cool the slurry to room temperature, take out the slurry, and after solid-liquid separation, washing and drying, the product (calcium silicate hydrate fiber additive ). The obtained product was subjected to XRD and SEM analysis. The main phases of the product are mullite, quartz, tobermullite, and calcium silicate hydrate gel. The calcium silicate hydrate fiber has a diameter of 0.01-0.1 μm, a length of 3-5 μm, and an aspect ratio of 50-100; the calcium-silicon atomic ratio of the calcium silicate hydrate fiber is 0.75.

[0067] Step (2):

[0068] The pouring slurry content (in parts by weight) is: 50 p...

Embodiment 3

[0071] step 1):

[0072] Be 1.0 and liquid-solid ratio according to calcium-silicon molar ratio be 20mL / g preparation slurry, add the NaOH of 5g / L to adjust the pH value of slurry (pH is 12); Gained suspension slurry is put into pressure reactor, stir Raise the temperature to 200°C, and react at a constant temperature under a pressure of 1.3MPa for 0.5h; after the reaction, cool the slurry to room temperature, take out the slurry, and after solid-liquid separation, washing and drying, the product (calcium silicate hydrate fiber additive ). The obtained product was subjected to XRD and SEM analysis. The main phases of the product are mullite, quartz, calcium silicate hydrate gel, tobermullite. The calcium silicate hydrate fiber has a diameter of 0.01-0.1 μm, a length of 1-3 μm, and an aspect ratio of 50-100; the calcium-silicon atomic ratio of the calcium silicate hydrate fiber is 0.75.

[0073] Step (2):

[0074] The pouring slurry content (in parts by weight) is: 50 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com