Method for treating acid wastewater from viscose plant

An acid waste water and viscose fiber technology, which is applied in filtration treatment, sedimentation treatment, multi-stage water treatment, etc., can solve the problems of being unsuitable for the treatment of high-concentrated salt waste water, large investment in evaporation system, and high operating costs, so as to reduce sewage Processing costs and production costs, saving equipment investment and operating costs, and realizing the effect of resource recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

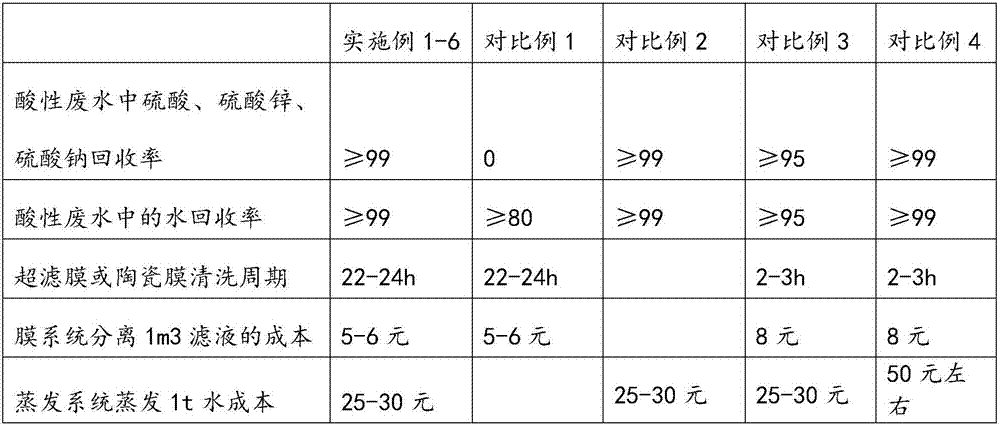

Examples

Embodiment 1

[0039] 200m at 85°C 3 / h acidic waste water (tested, containing 5g / L sulfuric acid, 15g / L sodium sulfate, 0.3g / L zinc sulfate, turbidity 50ntu) is concentrated in the collection tank with agitator, keep constant temperature at 85°C, and stir for 3 hours. The colloids and other impurities dissolved in the acidic wastewater will continue to collide with the agitation and agglomerate into large particles. After stopping the agitation and settling naturally for 2 hours, the large colloidal particles formed will be precipitated and deposited at the bottom of the collection tank with the action of gravity. According to the discharge temperature and heat exchange requirements, the acidic wastewater is divided into two parts in proportion for cooling treatment. The high-temperature acidic wastewater accounting for 75% of the total discharge is cooled to 30°C by means of multi-stage vacuum flashing. The vacuum flashing system produces 5.6t The secondary steam of more than 60°C / h enters...

Embodiment 2

[0043] 200m at 85°C 3 / h acidic waste water (tested, containing 5g / L sulfuric acid, 15g / L sodium sulfate, 0.3g / L zinc sulfate, turbidity 50ntu) is concentrated in the collection tank with agitator, keep the constant temperature at 85°C, and stir for 2.5 hours. The colloids and other impurities dissolved in the acid wastewater will continue to collide with the agitation and agglomerate into large particles. After stopping the agitation and settling naturally for 1.5 hours, the large colloid particles formed will precipitate and deposit at the bottom of the collection tank with the action of gravity. According to the discharge temperature and heat exchange requirements, the acidic wastewater is divided into two parts in proportion for cooling treatment. The high-temperature acidic wastewater accounting for 80% of the total discharge is cooled to 30°C by means of multi-stage vacuum flashing. The vacuum flashing system produces 5.6t The secondary steam of more than 60°C / h enters t...

Embodiment 3

[0047] 200m at 90°C 3 / h acidic waste water (tested, containing 10g / L sulfuric acid, 30g / L sodium sulfate, 0.8g / L zinc sulfate, turbidity 40ntu) is concentrated in the collection tank with agitator, keep the constant temperature at 88°C, and stir for 2 hours. The colloids and other impurities dissolved in the acid wastewater will continue to collide with the agitation and agglomerate into large particles. After stopping the agitation and settling naturally for 1.5 hours, the large colloid particles formed will precipitate and deposit at the bottom of the collection tank with the action of gravity. According to the discharge temperature and heat exchange requirements, the acidic wastewater is divided into two parts in proportion for cooling treatment. The high-temperature acidic wastewater accounting for 52% of the total discharge is cooled to 30°C by means of multi-stage vacuum flashing. The vacuum flashing system produces 4.6t The secondary steam of more than 60°C / h enters th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com