Cut-off knife device for nonmetal composite material for wind turbine blade girder laying

A technology of composite materials and wind turbine blades, which is applied in metal processing and other directions, can solve problems such as harsh production environment, personnel infection and allergies, and high labor intensity, and achieve a high degree of automation, improve the working environment, and reduce labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

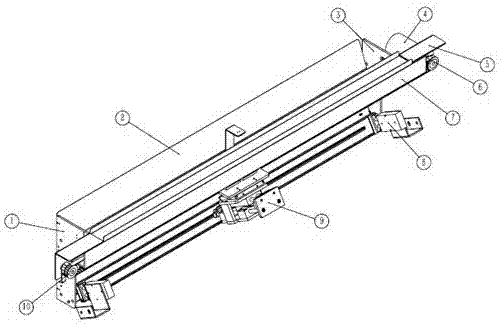

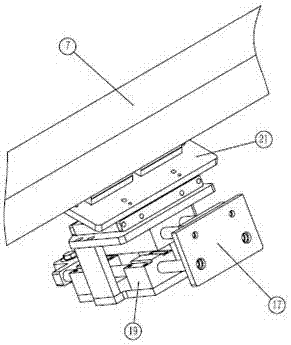

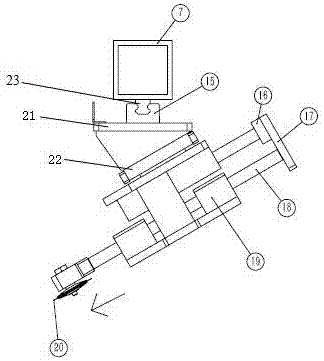

[0029] figure 1 A schematic structural diagram of an embodiment of the present invention is shown. like figure 1 , figure 2 and image 3 As shown, the invention provides a cutter device for laying non-metallic composite materials on the girder of wind power blades. The cutter assembly 9 is fixedly connected to the slider 15 through the slider connecting plate 21, and the slider 15 moves on the slide rail 23, and the slide rail 23 is installed on the lower bottom surface of the connecting square tube 7, so that the cutter assembly 9 reciprocates between the transverse widths, and the cutter assembly 9 is driven by the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com