Automatic tank cover integrated production line and preparation technology of tank cover

A production line and can lid technology, which is applied in the field of can lid automatic integrated production line and its preparation process, can solve the problems of low production efficiency of can body, low efficiency, and inability to meet modern production, so as to save labor costs, reduce operators, Effect of Improving Transfer Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing:

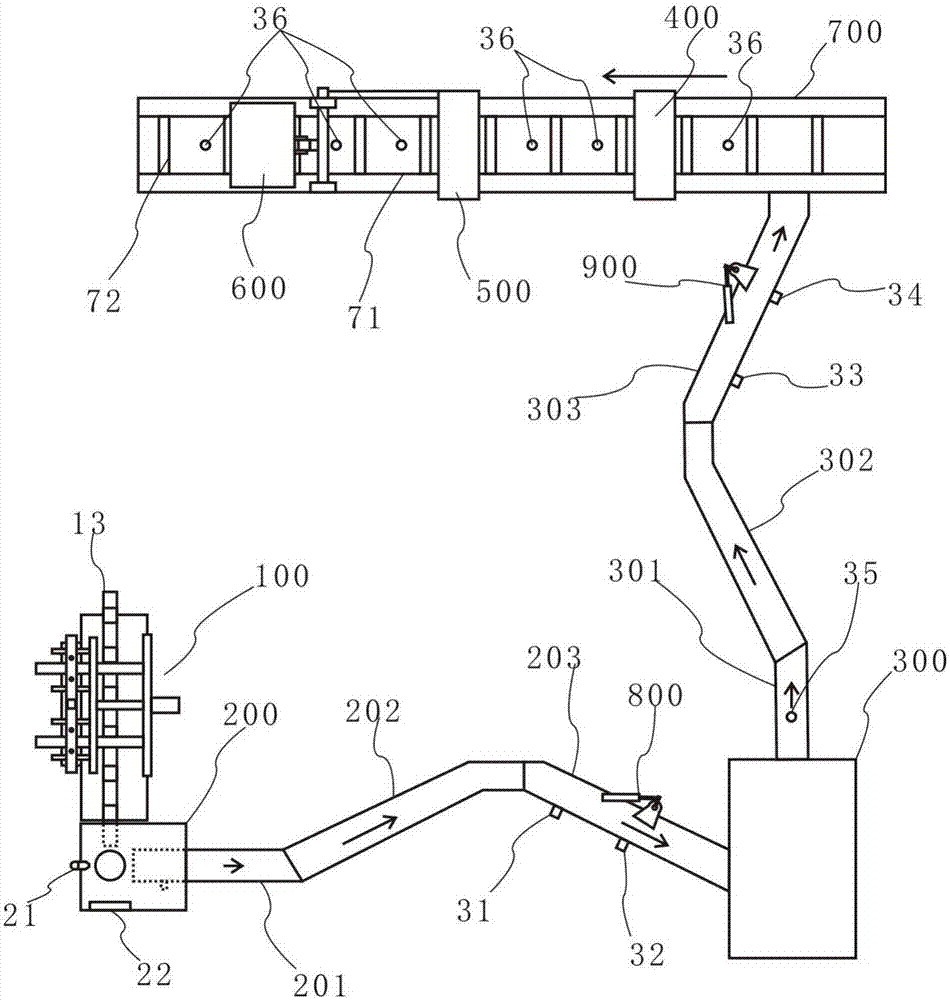

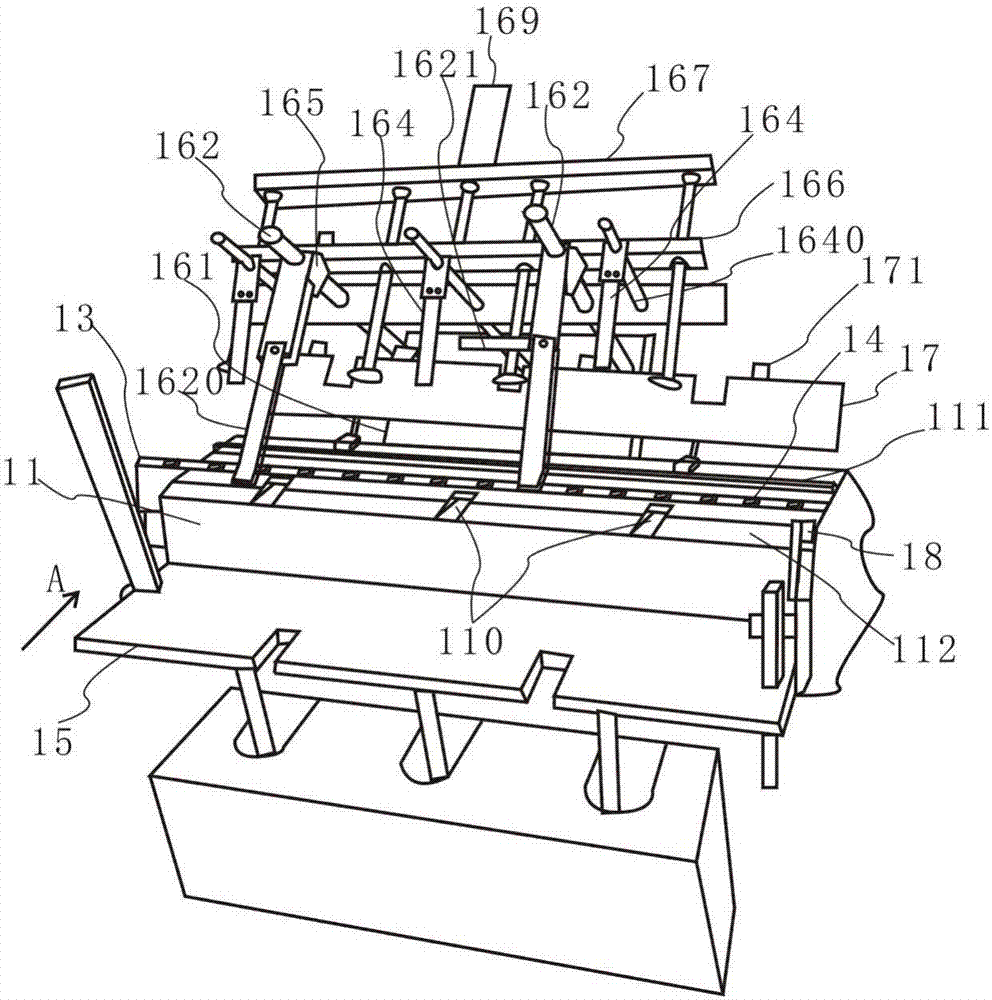

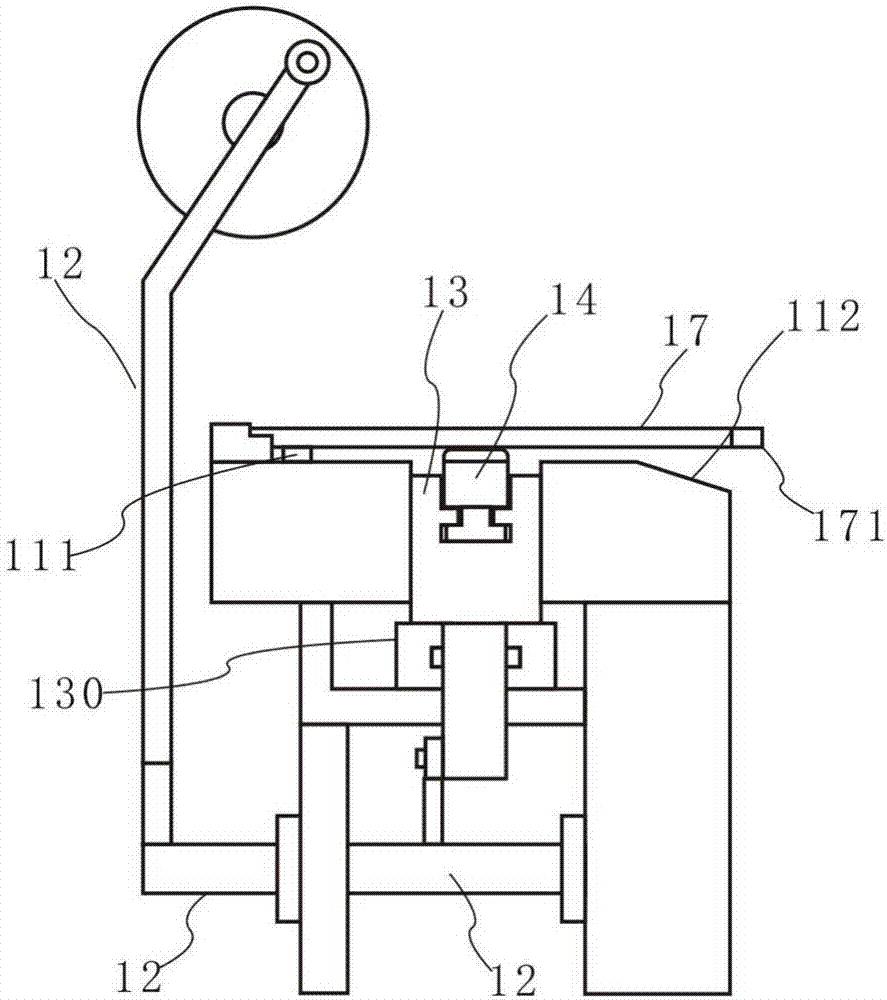

[0038] Such as Figure 1-11 As shown, this embodiment provides an automatic integrated production line for can lids, which is suitable for a square lid body composed of a top wall and four annular side walls connected to the top wall, including a feeder 100, a lid punching machine 200, a repair Edge punching machine 300, pre-bending punching machine 400, curling punching machine 500, dotting machine 600 and PLC electric control system, the output end of the feeder 100 is connected to the cutting and punching position of the punching and cap punching machine 200, so The punching and cap punching machine 200 is connected to the trimming punching machine 300 through the first conveying unit, and the trimming punching machine 300 is connected to the pre-bending punching machine 400 through the second conveying unit. Machine 400, crimping punching machine 500 and dotting machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com