Dual-component soluble hydrogel dressing and its preparation method

A soluble, hydrogel technology, applied in bandages, medical science and other directions, can solve the problems of poor wound fit, patient pain, secondary injury, etc., to effectively seal wounds, reduce patient pain, and have strong plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

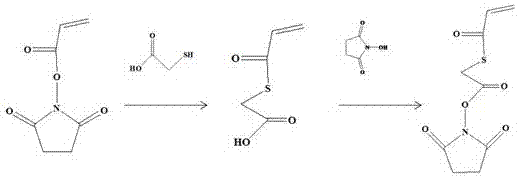

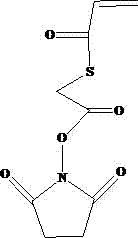

[0028] Mix 100g of N-acryloxy succinimide, 300g of thioglycolic acid, 10g of N,N-diisopropylethylamine, and 500g of dichloroethane, stir and react at room temperature for 24h to obtain a mixture; then, use 10% chlorine The mixture was washed with sodium chloride solution, the organic layer was dried with sodium sulfate, the solvent was evaporated, and the residue was purified by precipitation in ether to obtain an intermediate (yield=90%); 100g intermediate, 200g N-Hydroxythiosuccinimide NHS, 50g dicyclohexylcarbodiimide DCC, 300g dichloromethane DCM were mixed, the reaction was stirred at 30°C for 24h, the precipitate was filtered, the solvent was evaporated, and the residue was dissolved in ether Precipitation in the medium to obtain monomer B (yield=90%).

Embodiment 2

[0030] Mix 100g of N-acryloxysuccinimide, 50g of thioglycolic acid, 50g of N,N-diisopropylethylamine, and 500g of dichloroethane, stir and react at room temperature for 12h to obtain a mixture; then, use 10% chlorine The mixture was washed with sodium chloride solution, the organic layer was dried with sodium sulfate, the solvent was evaporated, and the residue was purified by precipitation in ether to obtain an intermediate (yield=92%); 100g intermediate, 500g N-Hydroxythiosuccinimide NHS, 500g dicyclohexylcarbodiimide DCC, 1000g dichloromethane DCM were mixed, and the reaction was stirred at 0°C for 24h, the precipitate was filtered, the solvent was evaporated, and the residue was dissolved in ether Precipitation in the medium to obtain monomer B (yield=91%).

Embodiment 3

[0032] Mix 100g of N-acryloxysuccinimide, 500g of thioglycolic acid, 3g of N,N-diisopropylethylamine and 100g of dichloromethane, stir and react at room temperature for 2~24h to obtain a mixture; then, use 10% chlorine The mixture was washed with sodium chloride solution, the organic layer was dried with sodium sulfate, the solvent was evaporated, and the residue was purified by precipitation in ether to obtain the intermediate (yield=95%); 100g intermediate, 50gN -Hydroxythiosuccinimide NHS, 100g dicyclohexylcarbodiimide DCC, 500g dichloromethane DCM were mixed, stirred for 2h at 50℃, filtered the precipitate, evaporated the solvent, and put the residue in ether Precipitation to obtain monomer B (yield=96%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com