Camomile green tea and processing method thereof

A processing method and chamomile technology, applied in the field of tea processing, can solve problems such as discomfort and affecting sleep

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

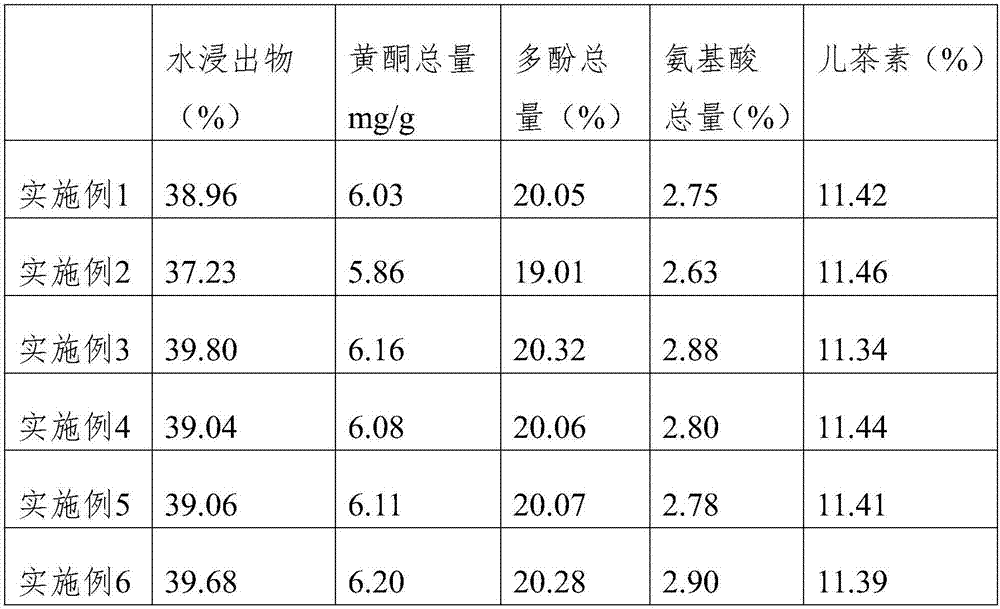

Examples

Embodiment 1

[0027] (1) Take by weighing 50kg of tea fresh leaves, and 50kg of fresh chamomile flowers as raw materials;

[0028] (2) Spread the fresh tea leaves, the thickness of which is 5cm, and the spreading time is 6 hours;

[0029] (3) The fresh tea leaves after spreading are carried out using a 6CCR-75 continuous hot-air cleaning machine, and the hot-air cleaning temperature is 280°C;

[0030] (4) cooling the tealeaves processed through finishing to normal temperature;

[0031] (5) Add 100% chamomile flowers to the tea leaves after cooling, and disperse evenly;

[0032] (6) tealeaves, chamomile mixture are packed in kneading machine, carry out kneading for the first time, described kneading, is to pass into the hot air of 72.5 ℃ to kneading machine, kneading machine spindle speed is 33r / min, control tealeaves, chamomile temperature at Knead at 41°C for 13.5 minutes, and rest for 3.5 minutes after the kneading is completed;

[0033] (7) The tealeaves after leaving standstill, cham...

Embodiment 2

[0038] (1) Take by weighing 50kg of tea fresh leaves, and 25kg of fresh chamomile flowers as raw materials;

[0039] (2) Spread the fresh tea leaves, the thickness of which is 4cm, and the spreading time is 5 hours;

[0040] (3) The fresh tea leaves after spreading are carried out using a 6CCR-75 continuous hot-air cleaning machine, and the hot-air cleaning temperature is 280°C;

[0041] (4) cooling the tealeaves processed through finishing to normal temperature;

[0042] (5) Add 50% chamomile flowers to the tea leaves after cooling, and disperse evenly;

[0043] (6) tealeaves, chamomile mixture are packed in kneading machine, carry out kneading for the first time, described kneading, is to pass into the hot air of 70 ℃ to kneading machine, kneading machine spindle speed is 33r / min, control tealeaves, chamomile temperature at Knead at 39°C for 13 minutes, and let stand for 3 minutes after the kneading is completed;

[0044] (7) The tealeaves after leaving standstill, chamom...

Embodiment 3

[0049] (1) Take by weighing 50kg of tea fresh leaves, and 100kg of fresh chamomile flowers as raw materials;

[0050] (2) Spread the fresh tea leaves, the thickness of which is 6cm, and the spreading time is 7 hours;

[0051] (3) The fresh tea leaves after spreading are carried out using a 6CCR-75 continuous hot-air cleaning machine, and the hot-air cleaning temperature is 280°C;

[0052] (4) cooling the tealeaves processed through finishing to normal temperature;

[0053] (5) Add 200% chamomile flowers to the tea leaves after cooling, and disperse evenly;

[0054] (6) tealeaves, chamomile mixture are packed in kneading machine, carry out kneading for the first time, described kneading, is to pass into the hot air of 75 ℃ to kneading machine, kneading machine spindle speed is 34r / min, control tealeaves, chamomile temperature at Knead for 14 minutes at 43°C, and stand for 4 minutes after the kneading is completed;

[0055](7) The tealeaves after leaving standstill, chamomile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com