Heat shrinkable pipe used in junction of multi-core fibers

A multi-core optical fiber and heat-shrinkable tube technology, which is applied in the coupling of optical waveguide, light guide, optics, etc., can solve the problems of residual air bubbles in the heat-shrinkable tube, twisted optical fibers, and occupying more racks, so as to achieve less rack space, The fiber is convenient and the effect of the fiber is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

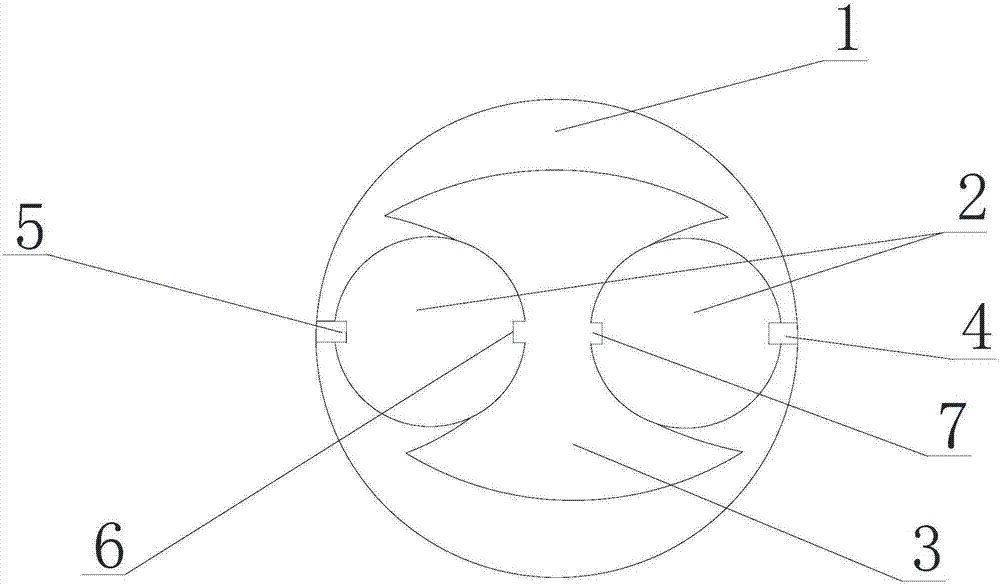

[0021] Such as figure 1 As shown, the heat-shrinkable tube used in multi-core optical fiber connection includes a heat-shrinkable tube 1, a heat-melt tube 2, a first strength member 3, and a second strength member 4. The number of the heat-melt pipes 2 is at least two, and the The melting tube 2 is arranged inside the heat-shrinkable tube 1, and the heat-melt tubes 2 are symmetrical along the central axis of the heat-shrinkable tube 1. The side of the thermal-melt tube 2 close to the heat-shrinkable tube 1 is provided with a groove 5, and the groove 5 is Square, arc-shaped or elliptical, the first reinforcement 3 is provided with a water chestnut 6 matching the groove 5, the first reinforcement 3 is placed in the groove 5 through the water chestnut 6 and connected with the heat-melt pipe 2, the groove 5 is along the A second groove 7 is provided on the symmetrical side of the central axis of the heat-melt tube 2, and the second groove 7 has the same shape as the groove 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com