Salt-contained waste liquid incineration device and technology lowering dust harm

A salty waste liquid and waste liquid technology, applied in lighting and heating equipment, incinerators, combustion types, etc., can solve problems that affect the service life of the incinerator lining, affect the stable operation of the burner, corrode the heat exchange surface of the waste heat boiler, etc. , to achieve the effects of reducing the risk of slagging, increasing service life and reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

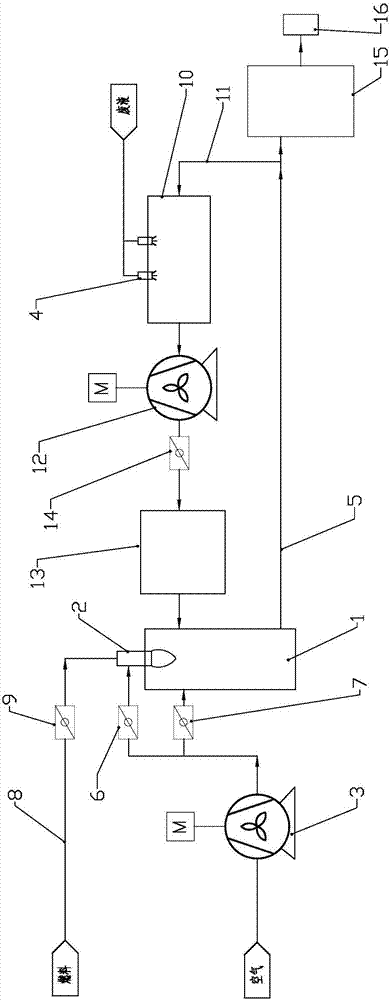

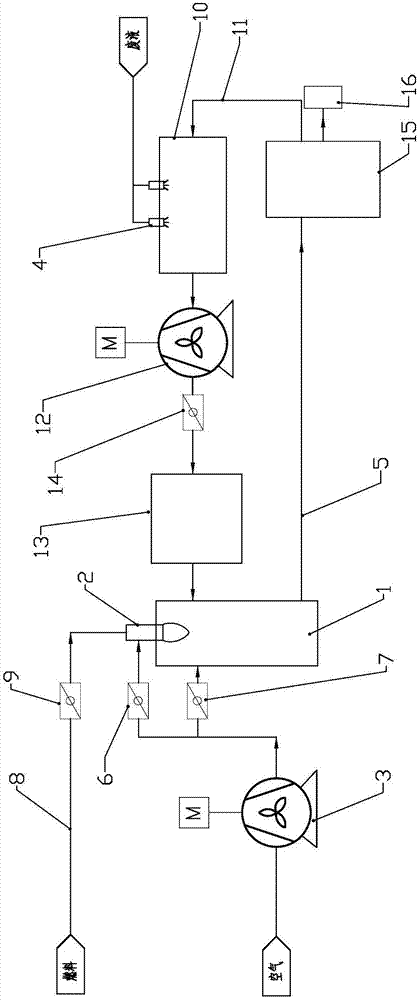

[0034] Refer to the attached figure 1 And attached figure 2 A salty waste liquid incineration equipment and process for reducing dust hazards of the present invention will be described in detail below.

[0035] A salt-containing waste liquid incineration device for reducing dust hazards of the present invention includes an incinerator 1, a burner 2, a blower 3 and a waste liquid atomizing nozzle 4, and the burner 2 is arranged on the upper part of the incinerator 1 to incinerate The lower part of the furnace 1 is provided with an outlet flue 5, and the blower 3 is respectively connected to the burner 2 and the incinerator 1 through pipelines, and the pipeline connecting the blower 3 and the burner 2 is provided with a first damper 6, and the blower 3 The pipeline connected to the incinerator 1 is provided with a second damper 7, the upper part of the burner 2 is provided with a fuel inlet pipe 8, the fuel inlet pipe 8 is provided with a valve 9, and the waste liquid is atomi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com