Efficient dust removal process for dust gas

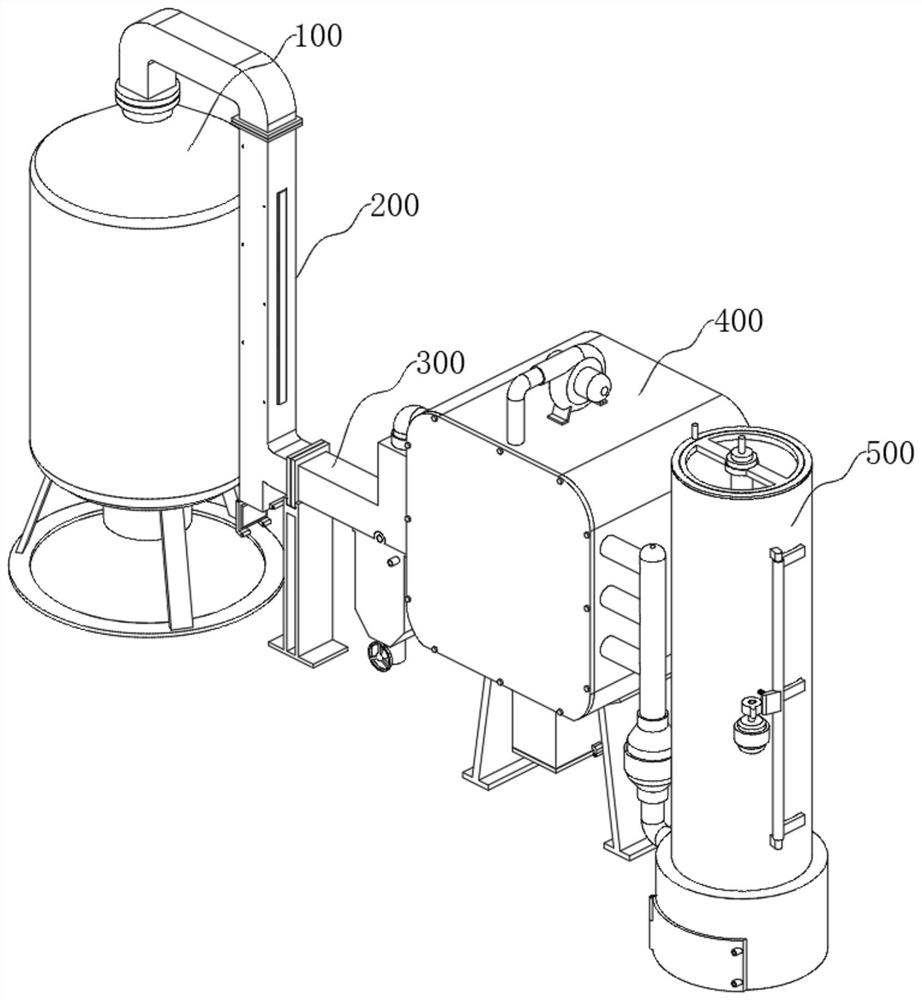

A gas and dust technology, applied in the field of high-efficiency dust removal technology, can solve the problems of increasing the dust removal pressure of a single dust removal device, increasing maintenance costs, shortening maintenance cycles, etc., achieving the effects of saving public resources, low cost input, and avoiding air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] The invention provides a high-efficiency dedusting process for dust gas, comprising the following steps:

[0079] 1. Preliminary removal stage of dust gas:

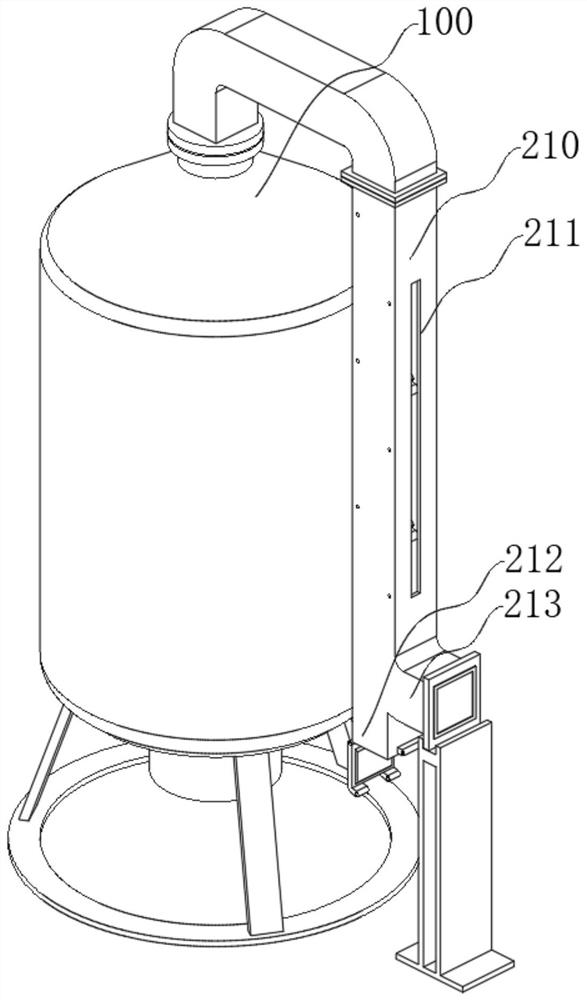

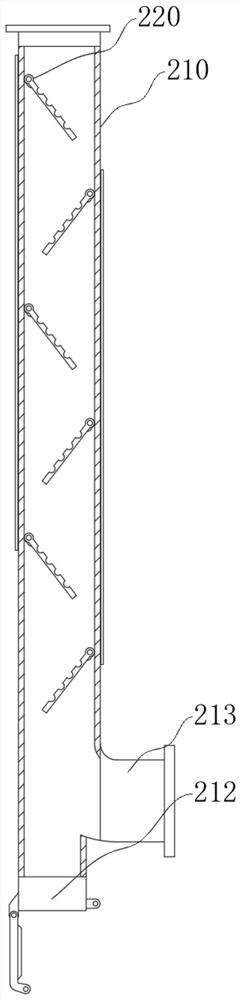

[0080] S1. First start the two electric push rods 225 in the dust and gas dedusting equipment to drive the linkage rod 222 to push down, press the arc block 2213 through the card slot 211 to make the shift block 2212 rotate around the pin in the collar 2210, so as to block the ash The bottom of the board 221 is tilted and placed in the middle of the ash-blocking pipe 210, and several ash-blocking boards 221 are unfolded to alternately form a drop-water structure;

[0081] S2. When the dust gas generated in the furnace 100 to be processed passes through the ash-blocking pipeline 210, it is blocked by a plurality of ash-blocking plates 221 and retains a large amount of dust in the groove 2211;

[0082] S3. When a small amount of gas with dust enters the filter tube 310, start the deceleration motor 350 to drive some...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com