Small-diameter sleeve window sidetrack drilling traction type well fixing method

A sidetracking and traction technology, which is applied in the field of traction cementing in slim hole casing windowing sidetracking wells, can solve the problems of high cost, polluted oil and gas layers, and poor quality, so as to prevent fracturing and overcome the annular gap Small, the effect of improving the cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical features, objectives and beneficial effects of the present invention more clearly understood, the present invention will be further described in detail below in conjunction with the embodiments. However, what has been described is only a part of the embodiments of the present invention, not all of the embodiments, and should not be construed as limiting the implementation scope of the present invention.

[0027] A slimhole casing sidetracking traction cementing method, the specific operation steps are:

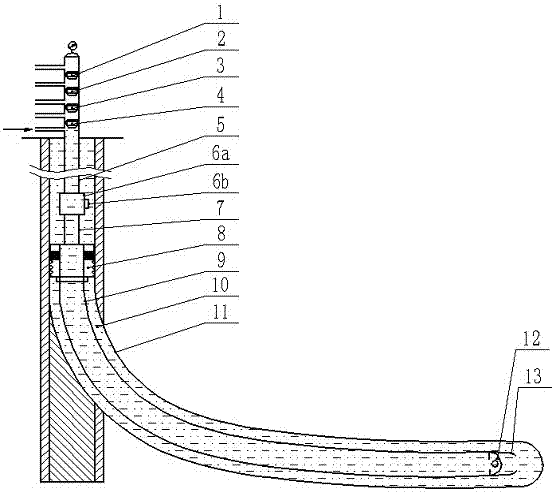

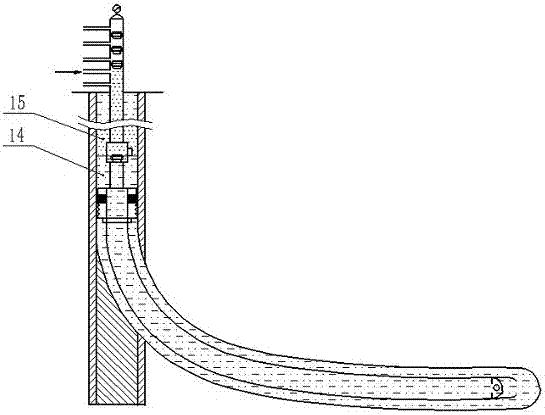

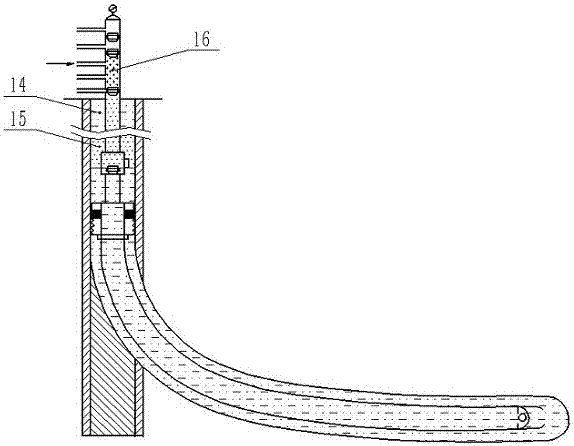

[0028] a. The upper part of the drill string I5 is connected to the cement head, the lower part of the drill string I5 is connected to the intelligent short-circuit circulation nipple 6a, the lower part of the intelligent short-circuit circulation nipple 6a is connected to the drill string II7, the lower part of the drill string II7 is connected to the liner hanger 8, and the lower part of the liner hanger 8 Connect the casing string, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com