Urine-penetration-resistant finishing solution for nonwovens and breathable urine-resistant nonwovens

A technology of non-woven materials and finishing liquid, which is applied in the field of non-woven materials, can solve the problems of poor air permeability, affecting the comfort and health of babies and users, and achieve the reduction of the chance of diaper rash, durable urine penetration resistance, The effect of excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of the breathable and urine-penetration-resistant nonwoven material of this embodiment includes the preparation of the base fabric and the urine-penetration-resistant finishing, as follows:

[0027] (1) Preparation of base fabric: spunbond, meltblown, meltblown, spunbond, hot rolling, winding.

[0028] Spunbond: extrude polypropylene slices through a screw extruder, filter, metering pump, spin with a spinning die, air draft, and form a web, with a fineness of about 20 microns and a weight of 6.5g / m 2 .

[0029] Meltblown: Extrude polypropylene chips through a screw extruder, filter, metering pump, spin with a spinning die, draw with hot air, cool, and form a web with a fineness of about 20 microns and a weight of 3.5g / m 2 .

[0030] Meltblown: Extrude polypropylene chips through a screw extruder, filter, metering pump, spin with a spinning die, draw with hot air, cool, and form a web with a fineness of about 3 microns and a weight of 3.5g / m 2 ....

Embodiment 2

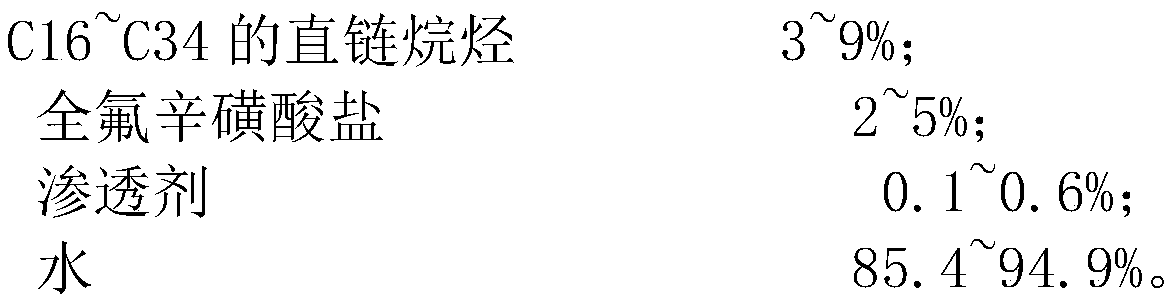

[0055] The preparation method of the breathable anti-urine nonwoven material of this embodiment is similar to that of Example 1, the difference is that the composition of the anti-urine finishing solution of this embodiment and its percentage in the anti-urine finishing solution are as follows:

[0056]

[0057]

[0058] Product performance test:

[0059]The breathable urine-resistant nonwoven material prepared in the above-mentioned Example 2 was tested for urine resistance and air permeability.

[0060] (1) Anti-urine performance test:

[0061] Test procedure: use artificial urine, the sample size is 50mm×50mm, test at least 3 thin breathable anti-urine nonwoven materials, use a cylinder with a height of 80mm and a diameter of 38mm to fill the artificial urine, place the breathable anti-urine nonwoven material Bottom test impervious time.

[0062] Test result: no penetration for 30 hours.

[0063] (2) Air permeability test:

[0064] Test steps: use a test area of ...

Embodiment 3

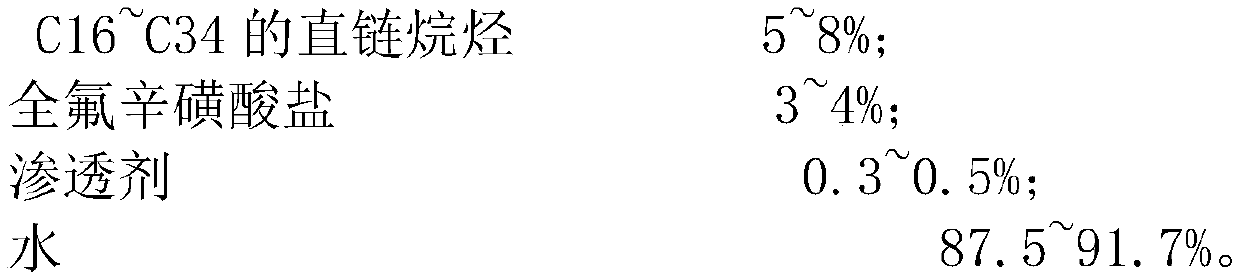

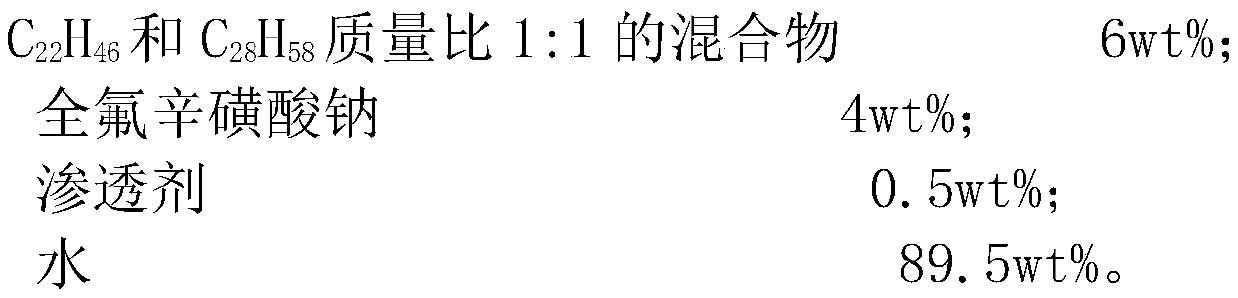

[0070] The preparation method of the breathable anti-urine nonwoven material of this embodiment is similar to that of Example 1, the difference is that the composition of the anti-urine finishing solution of this embodiment and its percentage in the anti-urine finishing solution are as follows:

[0071]

[0072] Product performance test:

[0073] The breathable urine-resistant nonwoven material prepared in the above-mentioned Example 3 was tested for urine resistance and air permeability.

[0074] (1) Anti-urine performance test:

[0075] Test procedure: use artificial urine, the sample size is 50mm×50mm, test at least 3 thin breathable anti-urine nonwoven materials, use a cylinder with a height of 80mm and a diameter of 38mm to fill the artificial urine, place the breathable anti-urine nonwoven material Bottom test impervious time.

[0076] Test result: no penetration for 30 hours.

[0077] (2) Air permeability test:

[0078] Test steps: use a test area of 20cm 2 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com