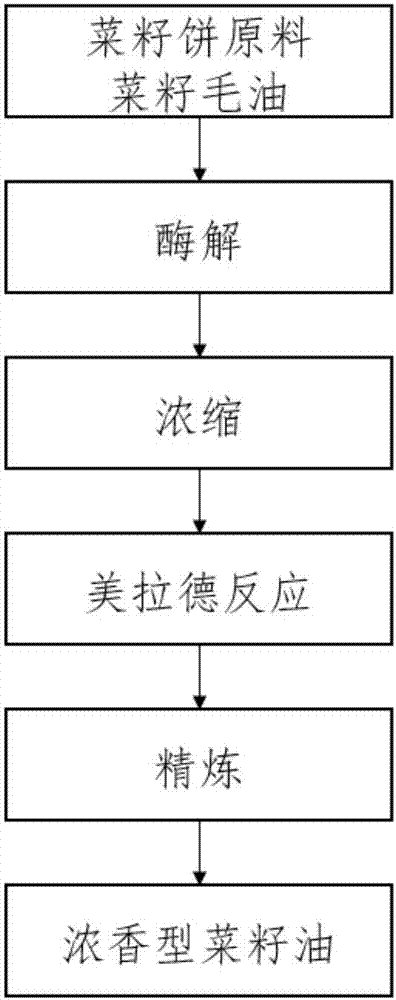

Production method of strongly-fragrant type rapeseed oil

A production method and technology of rapeseed oil, applied in the direction of fat oil/fat production, fat generation, edible oil/fat, etc., can solve the problems of oil protein denaturation, etc., and achieve the effect of reducing moisture, removing grease smell, and good oil quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Step 1. Preparation of rapeseed cake raw materials and rapeseed crude oil: clean the rapeseed, remove impurities and condition it, press it and filter to obtain the rapeseed cake and rapeseed crude oil, then put the rapeseed cake in a pot and stir-fry. The stir-frying temperature is 120-135°C, and the stir-frying time is 5-10 minutes. After stirring, the rapeseed cake raw material with a particle size of 60-80 meshes is obtained through sieving; among them, the moisture content of the rapeseed after impurity removal and conditioning is 16-16 18%, the moisture content in the rapeseed cake raw material is 6-8%, the residual oil content is 8-10%, the moisture and volatile matter of the rapeseed crude oil are ≤0.20 (%), and the insoluble impurities are ≤0.20 ( %), acid value ≤ 4.0 (mg / g), peroxide value ≤ 7.5 (mmol / kg).

[0023] Step 2, enzymatic hydrolysis: mix the raw materials of rapeseed cake and water according to the ratio of material to liquid: 1g: 3 ~ 5mL to obtain ...

Embodiment 1

[0028]Clean the rapeseed, remove impurities and condition it, squeeze it and filter it to get the rapeseed cake and rapeseed crude oil, then put the rapeseed cake in a pot and stir fry at a temperature of 120°C for 5 minutes. After sieving, the raw material of rapeseed cake with a particle size of 60 meshes was obtained; wherein, the moisture content of the rapeseed after impurity removal and conditioning was 16%, the moisture content in the raw material of rapeseed cake was 6%, and the residual oil content was 8%. . Mix the raw materials of rapeseed cake and water according to the material-to-liquid ratio of 1g: 3mL to obtain a mixed solution, and add a compound enzyme for enzymolysis. In the first stage, add sodium hydroxide solution to adjust the pH to 8.0, and perform the enzymolysis reaction at a temperature of 40°C 30 minutes; in the second stage, adjust the pH to 8.6, and perform the enzymolysis reaction at a temperature of 50°C for 60 minutes; in the third stage, adjus...

Embodiment 2

[0030] Clean the rapeseed, remove impurities and condition it, squeeze it and filter it to get the rapeseed cake and rapeseed crude oil, then put the rapeseed cake in a pot and stir fry at a temperature of 135°C for 10 minutes. After sieving, the raw material of rapeseed cake with particle size of 80 meshes is obtained; wherein, the moisture content of the rapeseed after impurity removal and conditioning is 18%, the moisture content of the raw material of rapeseed cake is 8%, and the residual oil content is 10% . Mix rapeseed cake raw materials and water according to the ratio of material to liquid: 1g: 5mL to obtain a mixed solution, and add compound enzymes for enzymolysis. In the first stage, add sodium hydroxide solution to adjust the pH to 8.4. Enzymolysis reaction for 60 minutes; second stage, adjust pH to 9.0, enzymolysis reaction at 55°C for 90 minutes; third stage, adjust pH to 8.6, enzymolysis reaction at temperature 50°C for 120 minutes, wait for enzymolysis reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peroxide value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com