Dustproof modifier used for glass baking varnish material, modified glass baking varnish paint and application thereof

A glass baking paint and modifier technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc. Production demand, simple operation, excellent cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

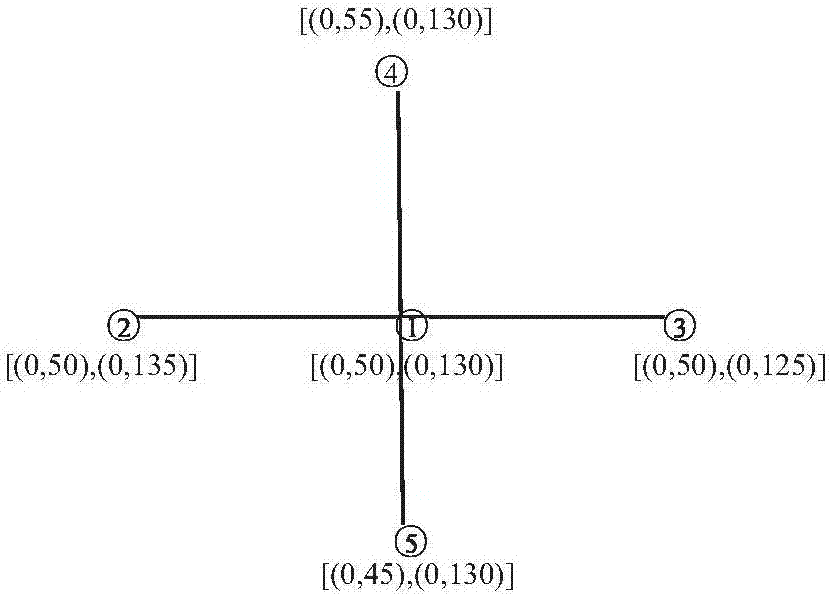

Image

Examples

Embodiment 1

[0052] Wash the 4 slides (glass slides) thoroughly, first with tap water, then with dilute hydrochloric acid, then with dilute ammonia, and finally with distilled water twice. Put the washed glass slides into a vacuum drying oven to dry at 120°C for later use, the same below.

[0053] Sodium dodecylbenzene sulfonate (SDBS), NH4Cl, Tween-80 and glass baking varnish (glass baking varnish of brand J-800 provided by Tongxiang Zhengda Paint Co., Ltd.) are mixed in a ratio of 0.1:0.05:1:100 Evenly, stir the modified glass baking varnish coating for half an hour at high speed.

[0054] Described modified glass baking varnish coating (experimental group) and the glass baking varnish that does not add modifying agent (control group: do not add dust-proof modifying agent described in the present invention), be coated on respectively on 4 slides, Apply two kinds of paint on different positions of the same glass slide, put it in a vacuum drying oven and bake at 160°C for half an hour, an...

Embodiment 2

[0059] Four slides were prepared as described in Example 1.

[0060] As described in Example 1, modified glass baking varnish and unmodified glass baking varnish were prepared.

[0061] As described in Example 1, the dried 4 slides were placed under natural ventilation conditions in the laboratory at an inclination of 60 °, and the surface sticking dust was observed with an optical microscopic analysis system every 10 days. The selected objective lens was plan4 / 0.10 160 / 0.17.

[0062] Follow the observation method described in Example 1.

[0063] After analysis and arrangement, on the sample placed at an angle of 60°, the average number of dust adhered to the modified paint surface is 33% less than that of the unmodified paint surface.

Embodiment 3

[0065] Wash the 4 slides thoroughly, first with tap water, then with dilute hydrochloric acid, then with dilute ammonia, and finally with distilled water twice. The washed slides were dried in a vacuum oven at 120°C for later use.

[0066] Sodium dodecylbenzene sulfonate (SDBS), NH4Cl, Tween-80 and glass baking varnish (glass baking varnish of brand J-800 provided by Tongxiang Zhengda Paint Co., Ltd.) were prepared in a ratio of 0.12:0.8:1:100 Mix evenly and stir the modified glass baking varnish coating for half an hour at high speed.

[0067] Apply the modified glass baking varnish (experimental group) and the glass baking varnish without modifier (control group) respectively on 4 glass slides, and apply two kinds of paints on different positions of the same glass slide, and put them into vacuum drying. Bake in the oven at 160°C for half an hour and set aside.

[0068] The dried 4 slides were placed in a laboratory with natural ventilation at an inclination of 45°, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com