Full-automatic high-speed sheet punching machine for filter element, sieve plate, filter disc, filter membrane and filter paper

A fully automatic, high-speed punching technology, applied in metal processing and other directions, to achieve the effects of good product consistency, convenient operation and good material compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

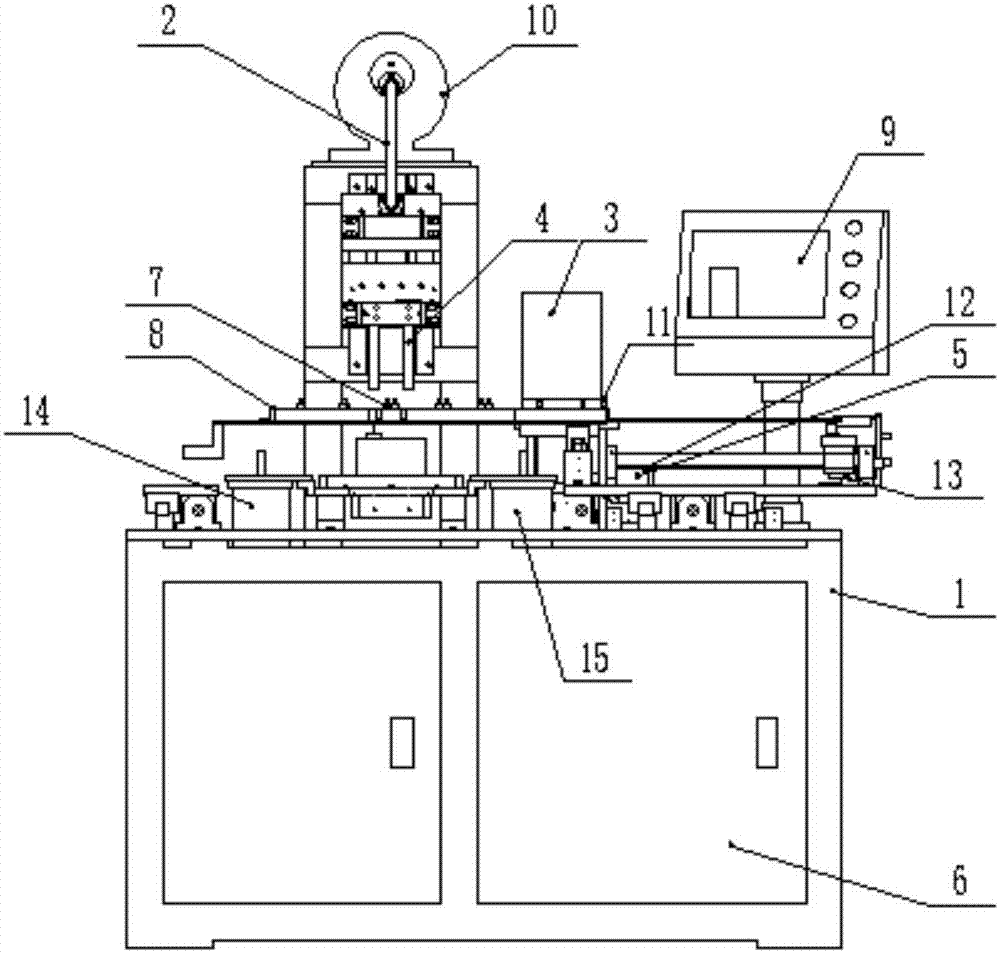

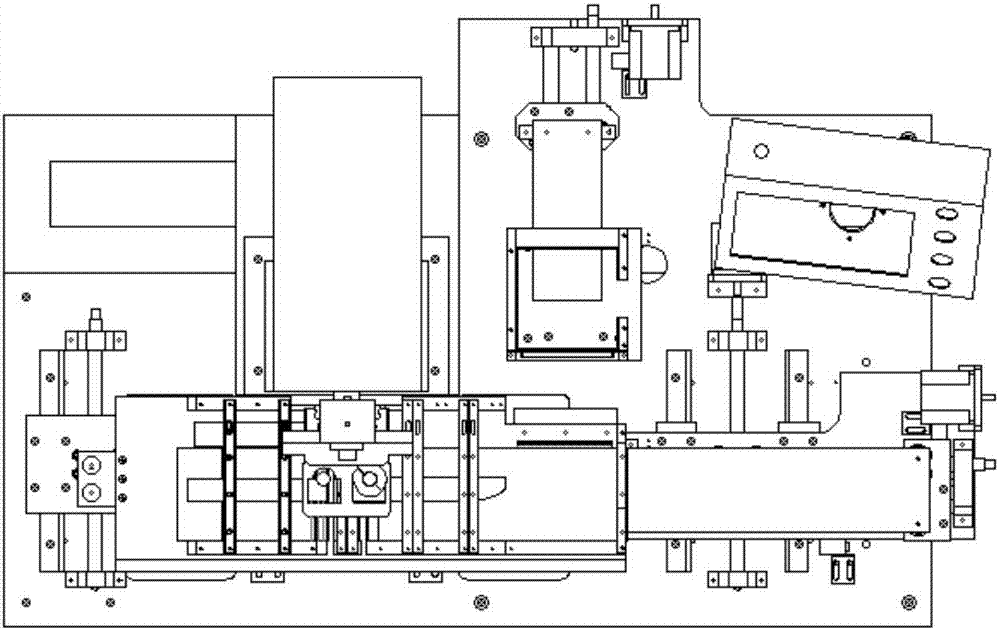

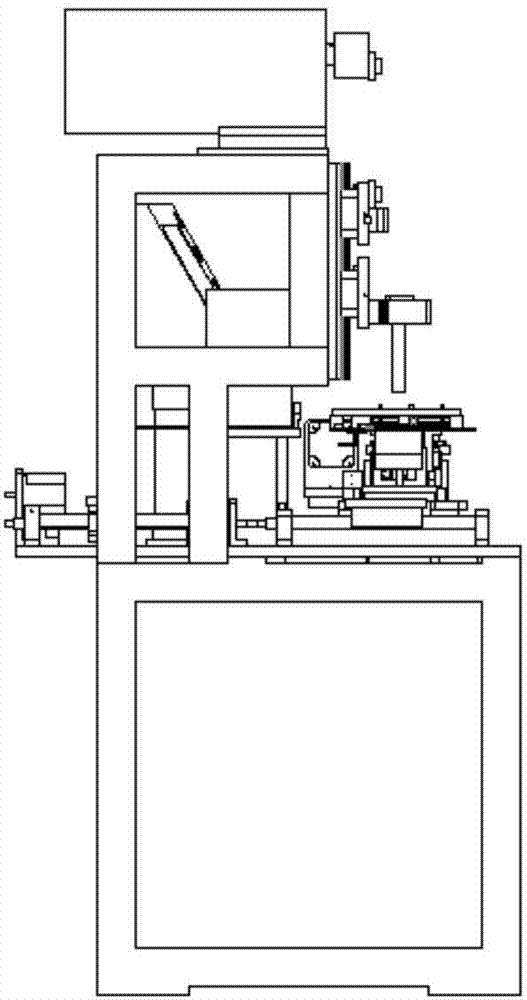

[0036] see Figure 1-3 , a fully automatic high-speed punching machine for filter element, sieve plate, filter sheet, filter membrane, filter paper, comprising a motor 10, a connecting rod 2, a spring 20, a plastic steel ejector rod 4, a storage plate slot 3, a storage plate slot pusher motor 11, and a punching platform 8. Punching left and right displacement module 5, punching left and right displacement module motor 13, punching front and rear displacement module motor 12, metal cutter head 7, punch rotation motor A14, receiving box 6, stainless steel metal frame 1 and touch screen 9 , the motor 10 is fixed on the top of the stainless steel metal frame 1, the connecting rod 2 and the spring 3 are connected on it, the plastic steel ejector rod 4 is installed on the lower part, and the detachable punching die is installed on the punching platform 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com