Manufacturing method of tubular pressure garment

A manufacturing method and technology of pressure garments, which are applied in the direction of tools for sewing clothes, etc., can solve the problems of affecting the inhibition effect of hypertrophic scars, using different ways to obtain methods, and different scopes of application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

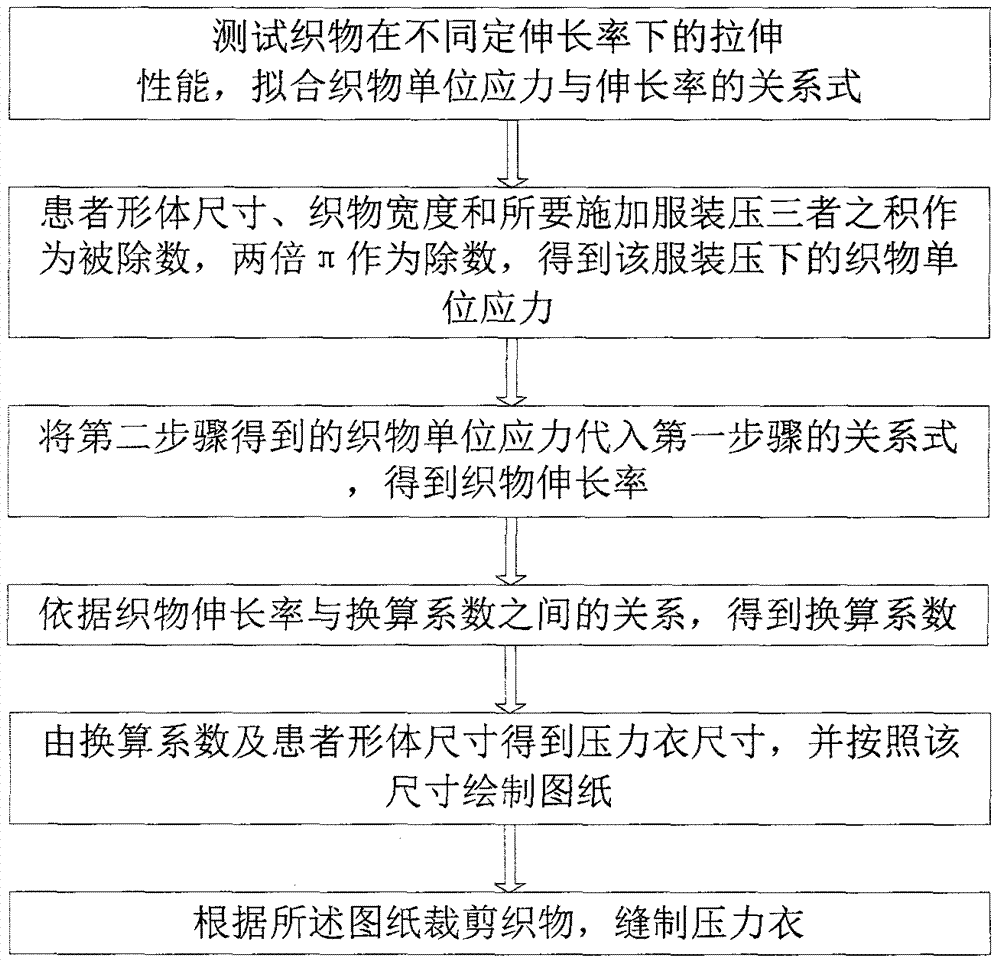

Method used

Image

Examples

Embodiment 1

[0020] Fabric information: The raw material is nylon / spandex (70 / 30), the fabric is flat, and the weight is 263g / m 2 , the longitudinal density is 30 circles / cm, and the transverse density is 26 circles / cm.

[0021] The fixed elongation ratios adopted for fabric stretching are respectively: 10%, 20%, 30%, 40%, 50% and 60%. The relationship between fabric unit stress (cN / cm) and elongation (%) is: unit stress=228.184×(elongation^0.815). Starting from the radial neck of the subject's wrist, take a test circle every 5cm along the length of the arm and measure the corresponding circumference (15cm, 16cm, 20cm, 23cm, 23cm, 23.4cm, 22.7cm, 23cm); the width of the sample for testing the constant elongation of the fabric is 5cm; the garment is pressed at 32hPa (about 24mmHg). The product of the patient's body size (circumference size), fabric width (sample width) and the garment pressure to be applied is used as the dividend, and twice π is used as the divisor to obtain the fabric u...

Embodiment 2

[0023] Example 1

[0024] Fabric information: The raw material is nylon / spandex (70 / 30), the fabric is warp knitted mesh, and the weight is 213g / m 2 , the longitudinal density is 14 circles / cm, and the transverse density is 14 circles / cm.

[0025] The fixed elongation ratios adopted for fabric stretching are respectively: 10%, 20%, 30%, 40%, 50% and 60%. The relationship between fabric unit stress (cN / cm) and elongation (%) is: unit stress=277.755×elongation+12.654. Starting from the radial neck of the subject's wrist, take a test circle every 5cm along the length of the arm and measure the corresponding circumference (15cm, 16cm, 20cm, 23cm, 23cm, 23.4cm, 22.7cm, 23cm); the width of the sample for testing the constant elongation of the fabric is 5cm; the garment is pressed at 32hPa (about 24mmHg). The product of the patient's body size (circumference size), fabric width (sample width) and the garment pressure to be applied is used as the dividend, and twice π is used as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com