A graphene film optical fiber F-P resonator capable of stress regulation and its manufacturing method

A method of Faber resonator and stress regulation, applied in instruments, converting sensor output, and using optical devices to transmit sensing components, etc., can solve the problems of inability to adjust the initial stress of the resonator, limiting the dynamic improvement of performance, and failure of the micro-resonator. , to achieve the effect of improving dynamic range and measurement accuracy, improving resonance performance and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this description, the principle of the present invention will be described through implementation. Other aspects, features and advantages of the present invention will become clear through the detailed description.

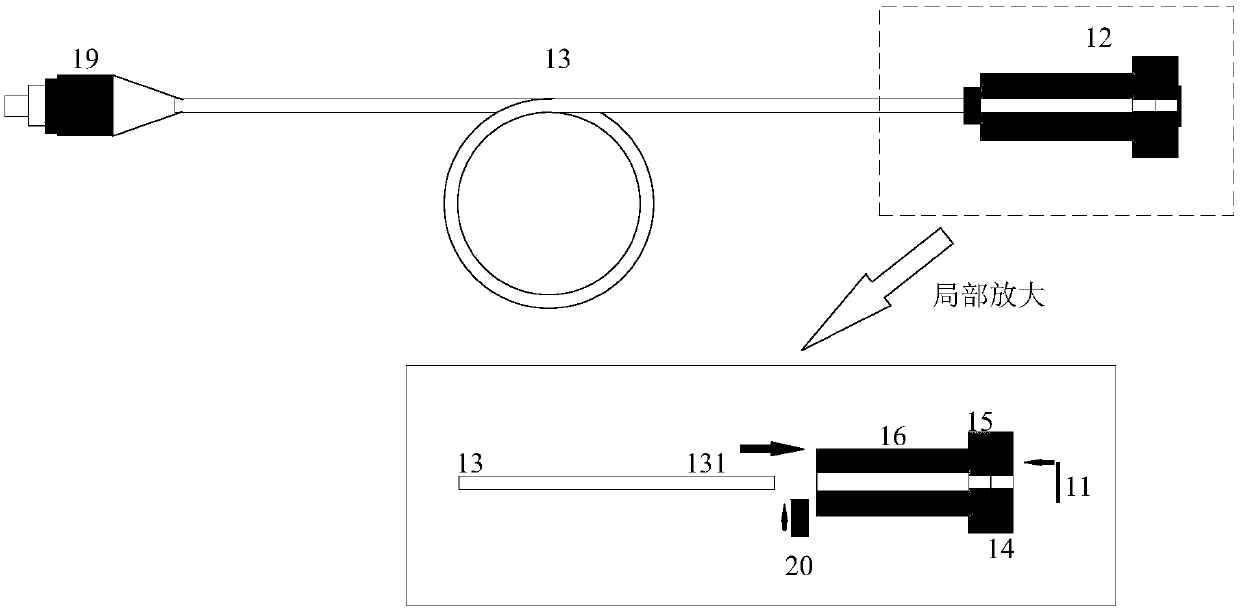

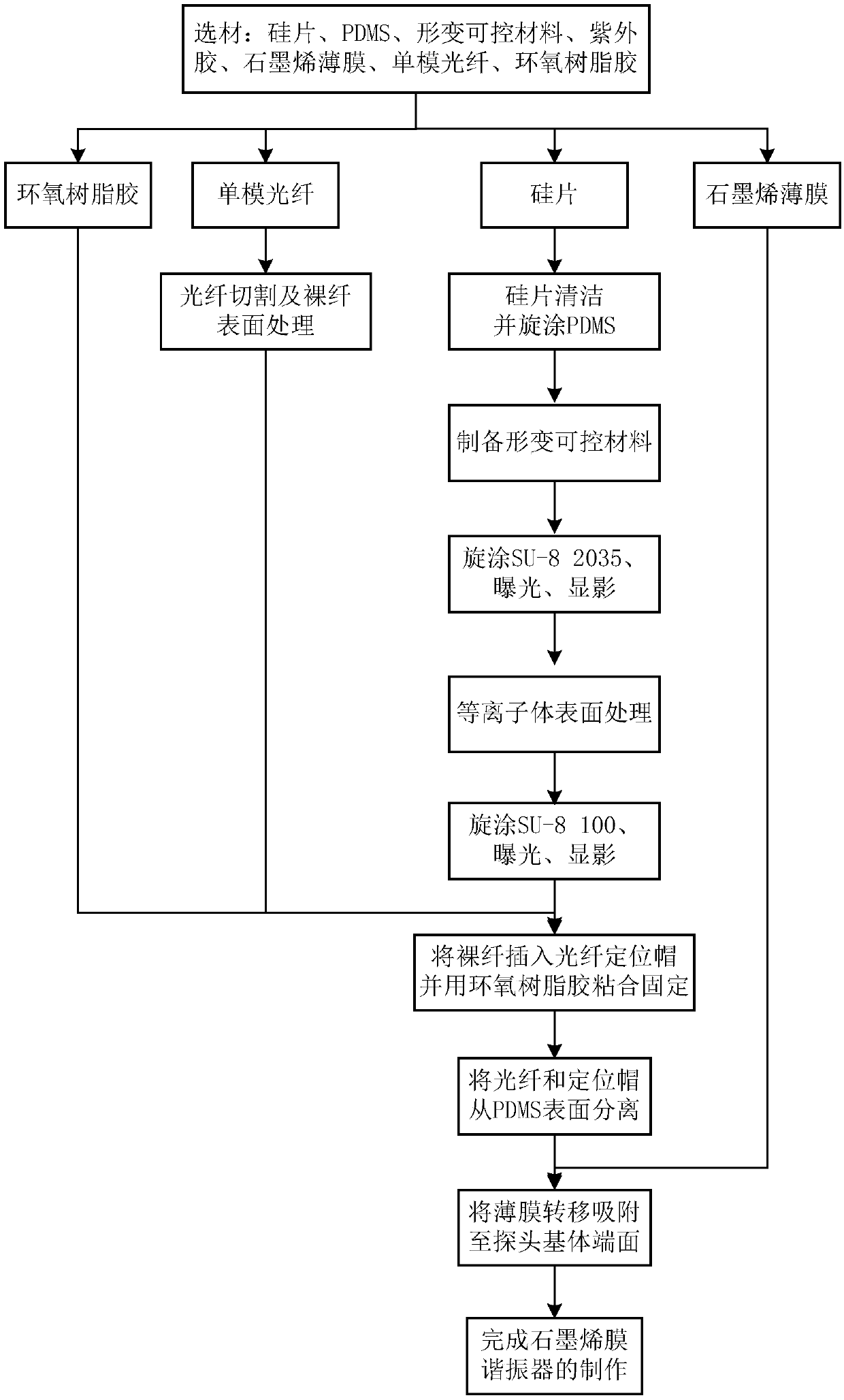

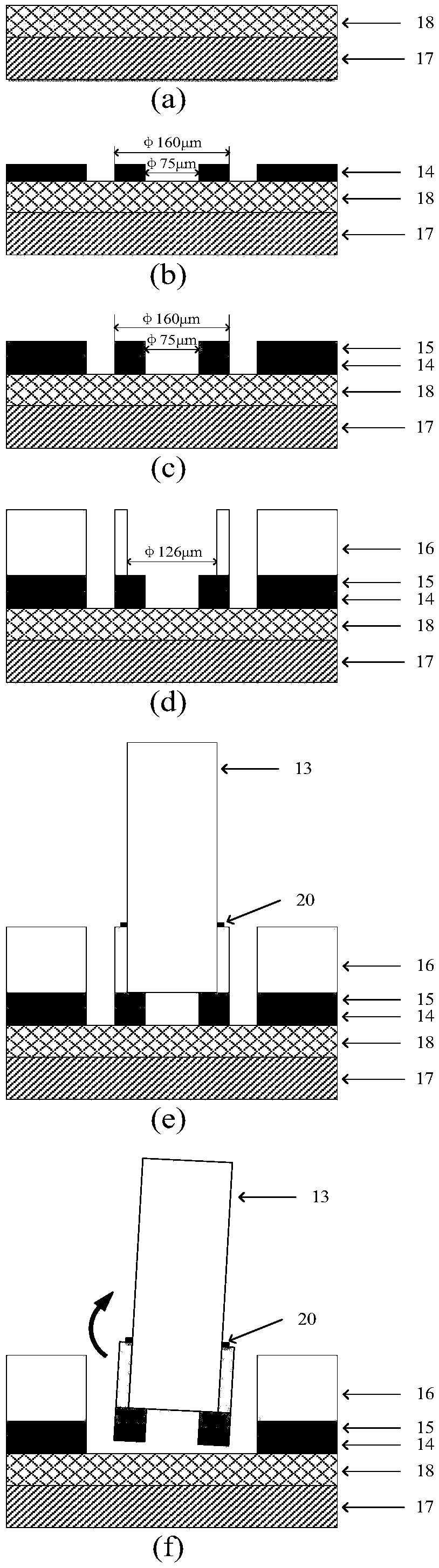

[0033] figure 1 It is a schematic diagram of the graphene film resonator structure of the present invention. The resonator is mainly composed of a graphene film 11 , an optical fiber positioning cap 12 and a single-mode optical fiber 13 . The graphene film 11 can be single-layer, few-layer or multi-layer, and its shape can be beam-type, circular, square, special-shaped or a combination of the above-mentioned different shapes; -8 photoresist is made, and its structure is three layers, and from right to left respectively is flexible substrate layer 14, SU-8 2035 ultraviolet glue 15 and SU-8 100 ultraviolet glue 16; Described flexible substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com