Smoke waste heat recovery system and method for biomass circulating fluidized bed boiler

A technology of waste heat recovery system and circulating fluidized bed, which is applied in the direction of preheating, steam generation, feed water heater, etc., can solve the problems of increasing exhaust gas temperature, increasing exhaust gas loss, corrosion, etc., and achieves increasing exhaust gas temperature , increase the loss of smoke exhaust, and improve the effect of continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

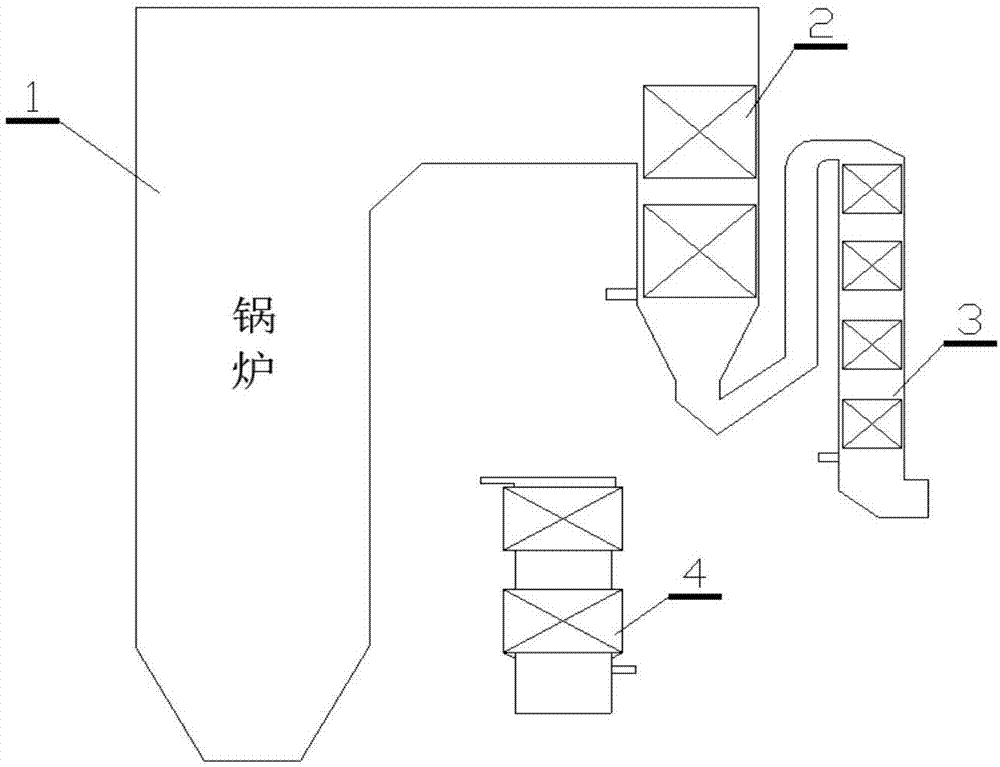

[0031] The invention discloses a biomass circulating fluidized bed boiler flue gas waste heat recovery system, such as figure 1 As shown, it includes: high temperature economizer 2, low temperature economizer 3 and air preheater 4.

[0032] The boiler 1 is composed of two tail shaft flues, and the high-temperature economizer 2 is located on the first shaft flue at the tail, which is composed of horizontal tube groups. The feed water is introduced into the tail flue from the inlet header located on the left side of the boiler 1. 2. From the outlet header located on the right side of boiler 1, introduce the right head of the steam drum through the connecting pipe.

[0033] The low-temperature economizer 3 is located on the flue of the second vertical shaft at the tail, and is composed of horizontal tube groups, arranged in parallel in two circle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com