A kind of super heavy oil demulsifier and preparation method thereof

A crude oil demulsifier and demulsifier technology, applied in the field of super heavy oil demulsifiers, can solve the problems of unsatisfactory demulsification, achieve clear and smooth oil-water interface, facilitate coalescence and flocculation, and have good synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

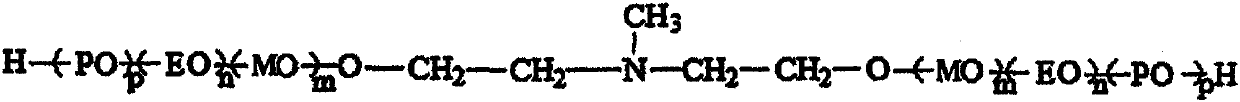

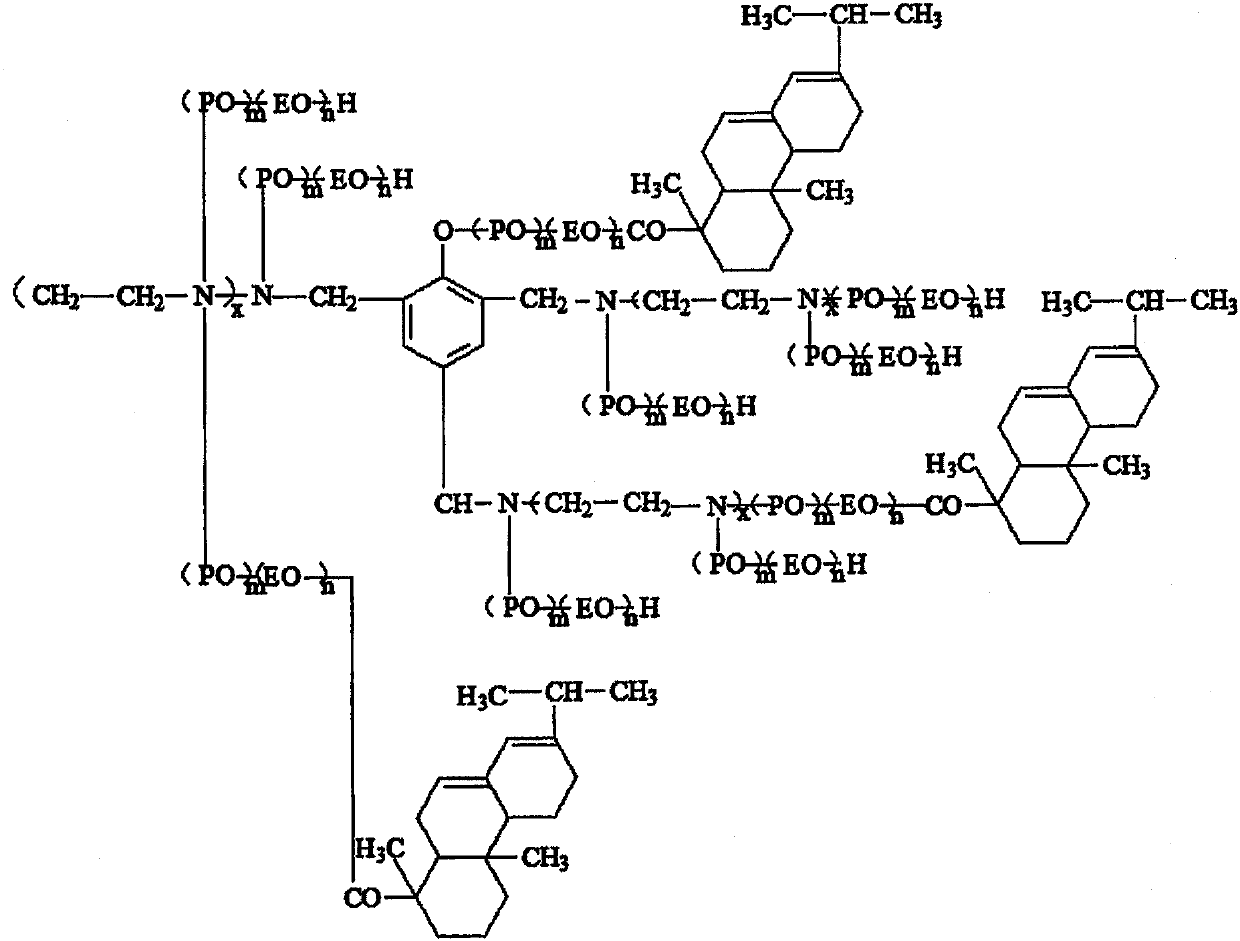

[0056] The preparation of demulsifier DMPRA comprises the following steps

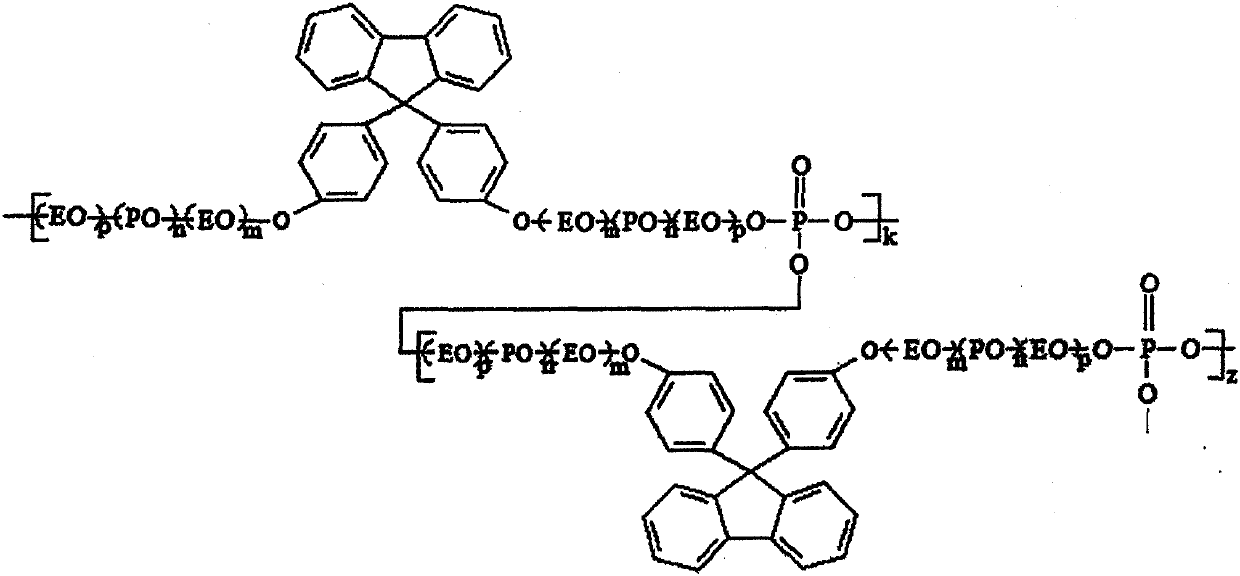

[0057] 1. Preparation of reverse oil head DP type crude oil demulsifier:

[0058] 1.1 Accurately weigh 1 part of bisphenol fluorene and 0.25% potassium hydroxide in total and transfer them into the reaction kettle, heat up and stir, keep warm for 30-45 minutes when the temperature reaches 225-230°C, and then turn on the vacuum (vacuum pressure≤- 0.09MPa) dehydration, the temperature is controlled at 225-230°C, the dehydration time is 35-40 minutes, after the dehydration is completed, 16 parts of ethylene oxide is continuously introduced, the reaction temperature is 225-230°C, and the reaction pressure is 0.15MPa-0.4 MPa; after passing through the ethylene oxide, continue to maintain the reaction temperature, when the pressure drops below 0.02MPa, mature for 30-45 minutes, cool down to 90-100°C and discharge to obtain the demulsifier intermediate DP01.

[0059] 1.2 Accurately weigh 1 portion of DP-1 an...

Embodiment 2

[0082] The preparation of demulsifier DMPRB comprises the following steps

[0083] 1. Preparation of reverse oil head DP type crude oil demulsifier:

[0084] 1.1 Accurately weigh 1 part of bisphenol fluorene and 0.2% potassium hydroxide in total and transfer them into the reaction kettle, heat up and stir, keep warm for 30-45 minutes when the temperature reaches 225-230°C, and then turn on the vacuum (vacuum pressure≤- 0.09MPa) dehydration, the temperature is controlled at 225-230°C, the dehydration time is 35-40 minutes, after the dehydration is completed, 18 parts of ethylene oxide is continuously introduced, the reaction temperature is 225-230°C, and the reaction pressure is 0.15MPa-0.4 MPa; after passing through the ethylene oxide, continue to maintain the reaction temperature, when the pressure drops below 0.02MPa, mature for 30-45 minutes, cool down to 90-100°C and discharge to obtain the demulsifier intermediate DP03.

[0085] 1.2 Accurately weigh 1 portion of DP03 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com