Device and method for rapidly and continuously synthesizing multi-morphology cesium lead halide cluster perovskite quantum dots

A cesium lead halide and perovskite technology is applied in the field of rapid and continuous synthesis of multi-morphology cesium lead halide cluster perovskite quantum dots. Problems such as large-scale production and uneven size of quantum dots can achieve the effect of low cost, high product quality and continuous synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

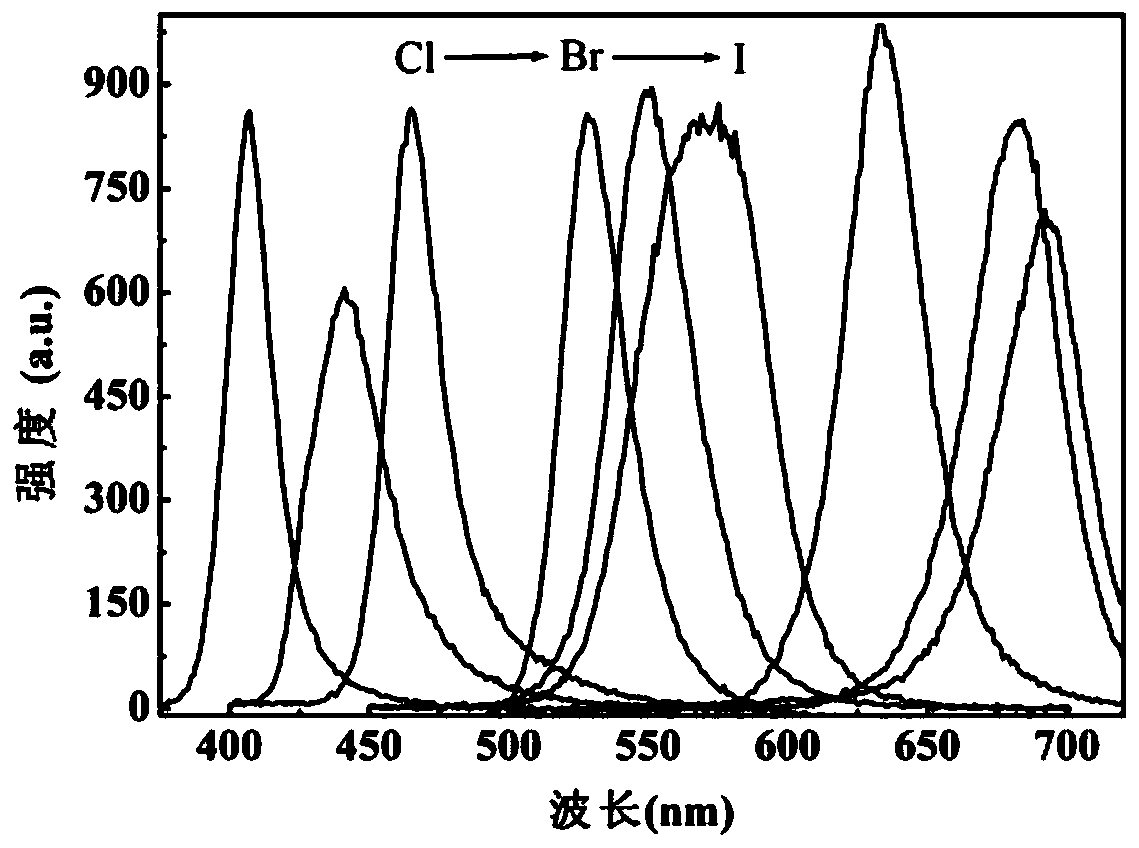

[0036] Cs precursor: 0.65g of CsCO 3 Dissolve 2.5ml of oleic acid and 18ml of octadecene to form a mixed solution. Heat the mixed solution at 150°C for 1 hour to obtain a light yellow and transparent Cs precursor. After cooling to room temperature, take 2ml of the Cs precursor solution and dilute it with octadecene to After the 26ml was fully stirred, a colorless and transparent solution with a total volume of 26ml was formed, and the colorless and transparent liquid was filled into a 20ml syringe.

[0037] PbBr 2 Precursor: 0.734g of PbBr 2 Dissolve in 20ml of octadecene, 3ml of oleic acid and 3ml of oleylamine to form a mixed solution with a total volume of 26ml. After the mixed solution is heated at 150°C for 1 hour, a light yellow transparent liquid is obtained. After cooling to room temperature, take 20ml of the mixed solution Fill into a 20ml syringe.

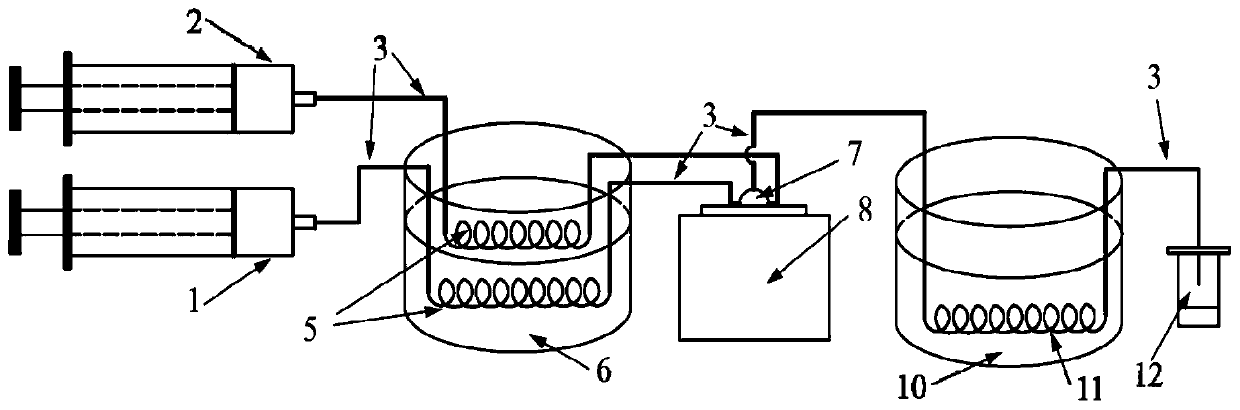

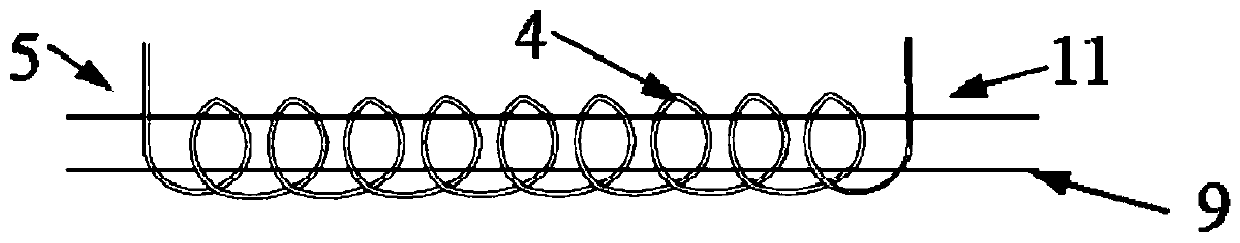

[0038] Attached figure 1 The shown rapid synthesis perovskite quantum dot device uses polytetrafluoroethylene with ...

Embodiment 2

[0042] Cs precursor: 0.65g of CsCO 3 Dissolve 2.5ml of oleic acid and 18ml of octadecene to form a mixed solution. Heat the mixed solution at 150°C for 1 hour to obtain a light yellow and transparent Cs precursor. After cooling to room temperature, take 2ml of the Cs precursor solution and dilute it with octadecene to After the 26ml was fully stirred, a colorless and transparent solution with a total volume of 26ml was formed, and the colorless and transparent liquid was filled into a 20ml syringe.

[0043] PbBr 2 :PbI 2 (1:1) precursor: 0.3670g of PbBr 2 and 0.4601 g of PbI 2 Dissolve in 20ml of octadecene, 3ml of oleic acid and 3ml of oleylamine to form a mixed solution with a total volume of 26ml. After the mixed solution is heated at 150°C for 1 hour, a light yellow transparent liquid is obtained. After cooling to room temperature, take 20ml of the mixed solution Fill into a 20ml syringe.

[0044] Attached figure 1 The shown rapid synthesis perovskite quantum dot dev...

Embodiment 3

[0048] Cs precursor: 0.65g of CsCO 3 Dissolve 2.5ml of oleic acid and 18ml of octadecene to form a mixed solution. Heat the mixed solution at 150°C for 1 hour to obtain a light yellow and transparent Cs precursor. After cooling to room temperature, take 2ml of the Cs precursor solution and dilute it with octadecene to After the 26ml was fully stirred, a colorless and transparent solution with a total volume of 26ml was formed, and the colorless and transparent liquid was filled into a 20ml syringe.

[0049] PbBr 2 :PbI 2 (1:3) precursor: 0.1835g of PbBr 2 and 0.6901 g of PbI 2 Dissolve in 20ml of octadecene, 3ml of oleic acid and 3ml of oleylamine to form a mixed solution with a total volume of 26ml. After the mixed solution is heated at 150°C for 1 hour, a light yellow transparent liquid is obtained. After cooling to room temperature, take 20ml of the mixed solution Fill into a 20ml syringe.

[0050] Attached figure 1 The shown rapid synthesis perovskite quantum dot dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com