Assembled type spinneret plate with a plurality of spinning nozzles

A multi-nozzle, assembled technology, which is applied in the directions of spinneret assemblies, textiles and papermaking, etc., can solve the problems of unfavorable mass spinning of hollow fiber ultrafiltration membranes, unfavorable automatic spinning and yarn collection, etc. Stable and reliable constant temperature and uniform distribution of flow channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

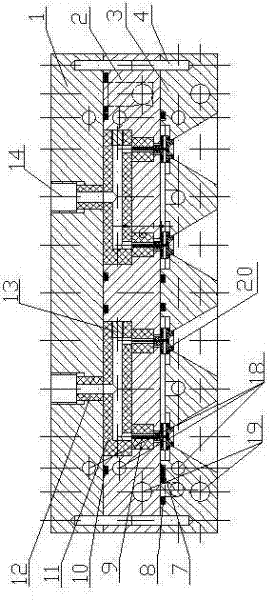

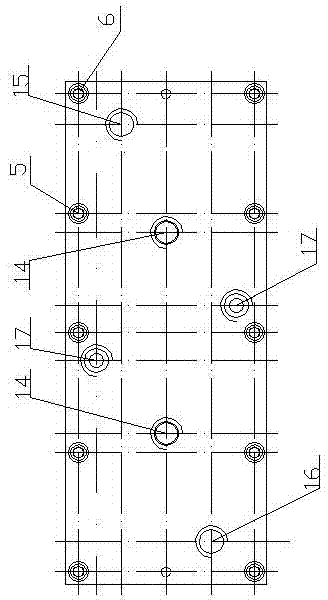

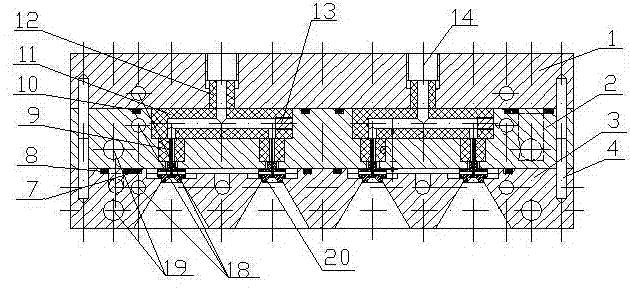

[0011] The assembled multi-nozzle spinneret structure of the present invention is as figure 1 and figure 2 As shown, in this embodiment, it is a spinneret with two inputs and four outputs, that is, four spinnerets 20 . The assembled multi-nozzle spinneret includes an upper spray plate 1, a middle spray plate 2 and a lower spray plate 3, and the upper spray plate 1, the middle spray plate 2 and the lower spray plate 3 are fixedly connected by cylindrical pins 4 installed at both ends of the interior. , and fixed by screws 5 and 6, two internal condensate inlets 14, a constant temperature liquid inlet 15, two film liquid inlets 17 and a constant temperature liquid outlet 16 are provided on the upper spray plate 1, the upper spray plate 1, and the middle spray plate 2 A film liquid channel 18 is provided inside the lower spray plate 3 , and a constant temperature liquid flow channel 19 is provided inside the middle spray plate 2 and the lower spray plate 3 . The inner condensa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com