Preparation method of soft glow marble

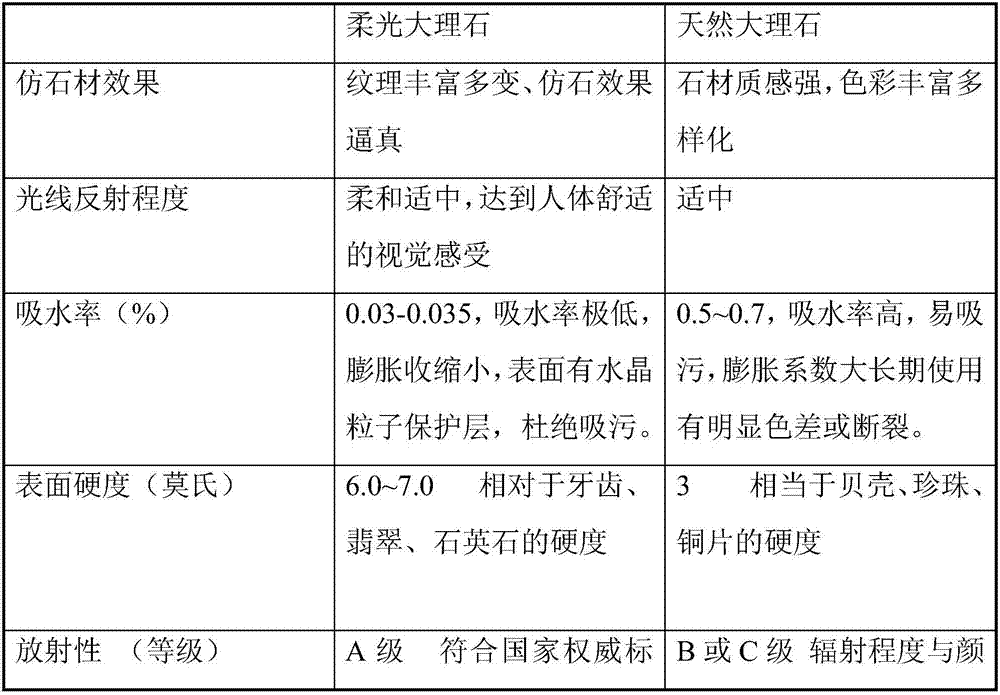

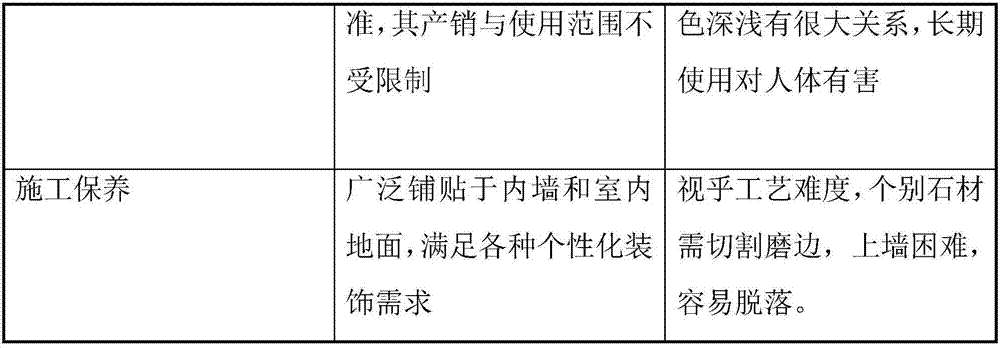

A marble and soft light technology, applied in the field of feed granulator, can solve the problems of high surface gloss, unsatisfactory decorative effect, weak surface texture, etc., to achieve visual comfort, reduce product reflectivity, and improve texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

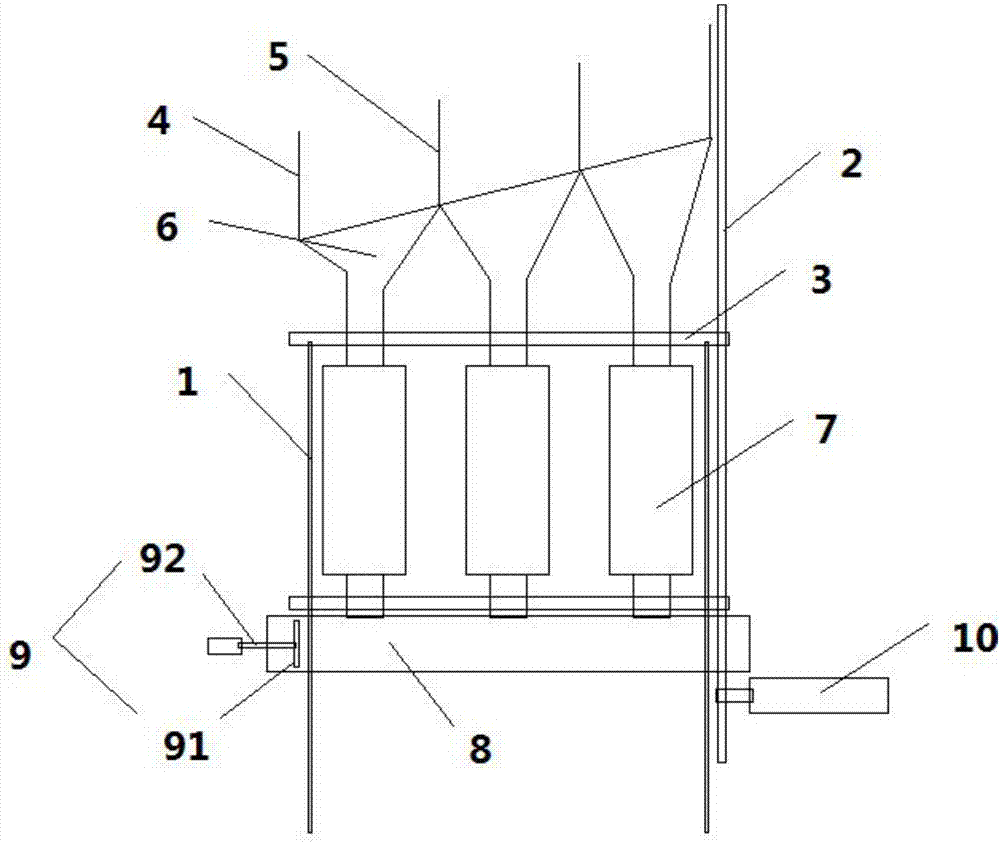

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0034] A preparation method for soft light marble, comprising the following steps:

[0035] Step 1. Select and mix raw materials, wherein the raw materials include by weight: 26 parts of black mud, 4 parts of magnesia mud, 3 parts of white mud, 7 parts of stone powder, 14 parts of potassium sodium sand, 28 parts of medium-temperature sand, and 8 parts of low-temperature sand Sand and 10 parts of high alumina.

[0036] Step 2. Put the raw materials into a batch ball mill for intermittent grinding until the fineness is 6-8%, and then place them in a continuous ball mill for continuous ball milling until the fineness is 1.0-1.3%;

[0037] Step 3. Put the mud obtained from the ball mill into the mud tank until it is homogenized inside;

[0038] Step 4, using a spray drying towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com