GO (graphene oxide) and nano mineral powder synergistically dispersed CNT (carbon nanotube) modified nano building material as well as preparation method and application thereof

A building material and nanotechnology, applied in the field of nanomaterials, can solve the problems of weak bonding surface between CNT deposition layer and cement base layer, weak bonding interface between CNT and cement, and a large number of bubbles in surfactants, so as to achieve good piezoresistive transmission. Sensitive characteristics, excellent mechanical toughness, good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

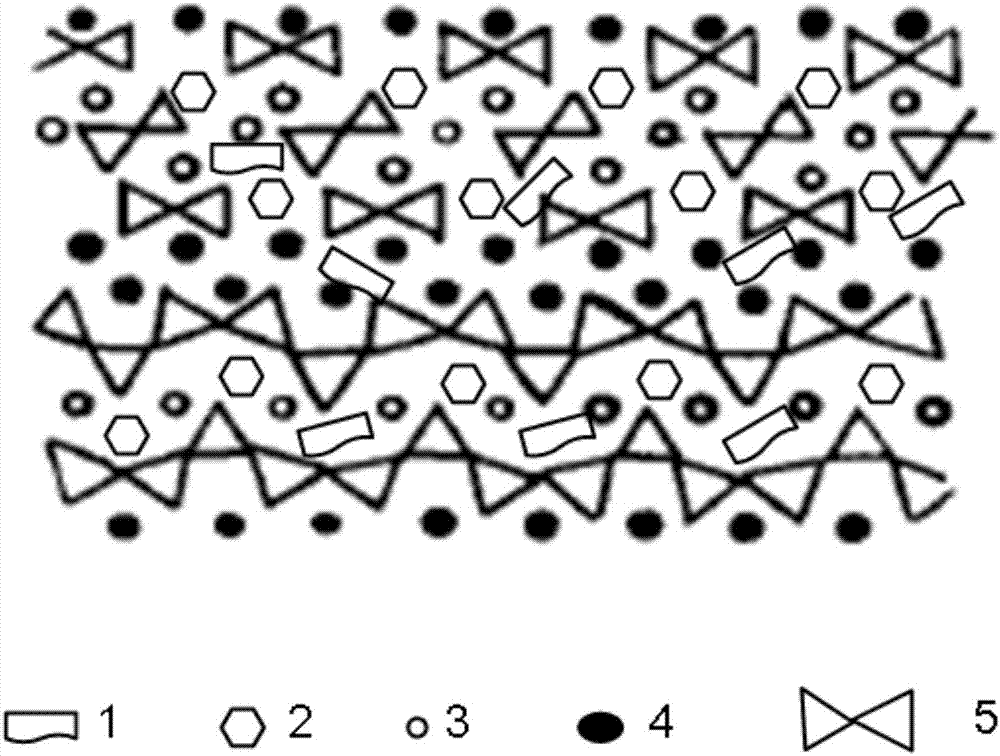

Image

Examples

Embodiment 1

[0050] The preparation steps of the GO and nano-mineral powder synergistically dispersed CNT modified nano-building materials are as follows:

[0051] (1) Preparation of GO synergistically dispersed CNT suspension

[0052] Step 1: Add 0.1g of GO dispersion with 30% oxygen content into 300mL water dissolved in 5g of polycarboxylate superplasticizer, then add 1g of CNT powder with a diameter of 10-20nm and a length of 5-15μm, and then carry out Ultrasonic treatment, the corresponding process is to stop for 1s every 10s of ultrasound; through testing the GO / CNT / water reducer mixture in GO, The UV absorbance at the characteristic peaks (230nm, 220nm) of CNT's UV spectrum, combined with the consumed ultrasonic energy and the peak absorbance, comprehensively weighed and obtained the optimal ultrasonic treatment energy of 60KJ. Using the optimized ultrasonic energy treatment process, the ink-like GO / CNT dispersion mother liquid was finally prepared for future use.

[0053] Step 2: ...

Embodiment 2

[0065] The preparation steps of the GO and nano-mineral powder synergistically dispersed CNT modified nano-building materials are as follows:

[0066] (1) Preparation of GO synergistically dispersed CNT suspension

[0067] Step 1: Add 0.1g of GO dispersion with 30% oxygen content into 300mL of water dissolved in 5g of naphthalene sulfonate superplasticizer FDN, then add 50g of CNT dispersion with a concentration of 2wt%, and then perform ultrasonication Treatment, the corresponding process is to stop for 1s every 10s of ultrasound; by testing the GO / CNT / water reducer mixture under the ultrasonic treatment energy of 0KJ to 100KJ (step 10KJ), the corresponding GO / CNT / water reducer mixture is in GO, CNT The UV absorbance at the characteristic peaks (230nm, 220nm) of the UV spectrum, combined with the consumed ultrasonic energy and the peak absorbance, comprehensively weighed and obtained the optimal ultrasonic treatment energy of 60KJ. Using the optimized ultrasonic energy treat...

Embodiment 3

[0078] The preparation steps of the GO and nano-mineral powder synergistically dispersed CNT modified nano-building materials are as follows:

[0079] (1) Preparation of GO synergistically dispersed CNT suspension

[0080] Step 1: Add 25mL of GO dispersion with a concentration of 4mg / mL and an oxygen content of 41-50% into 300mL of water dissolved in 5g of aliphatic superplasticizer, and then add 1g of GO dispersion with a diameter of 1-2nm and a length of 2- The single-walled CNT powder of 8 μm is then subjected to ultrasonic treatment, and the corresponding process is to stop for 1 second every 10 seconds of ultrasonic treatment; by testing the GO / CNT / water reducer mixture, the corresponding GO / CNT is treated under the ultrasonic treatment energy from 0KJ to 100KJ (10KJ is taken in steps). The UV absorbance of the water-reducing agent mixture under the characteristic peaks (230nm and 220nm) of the UV spectrum of GO and CNT, combined with the consumed ultrasonic energy and ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com