Oxidable volatile organic matter treatment device and use method thereof

A technology for volatile organic compounds and treatment devices, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of poor oxidizable volatile organic compounds and secondary pollution, so as to reduce secondary pollution and increase The effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

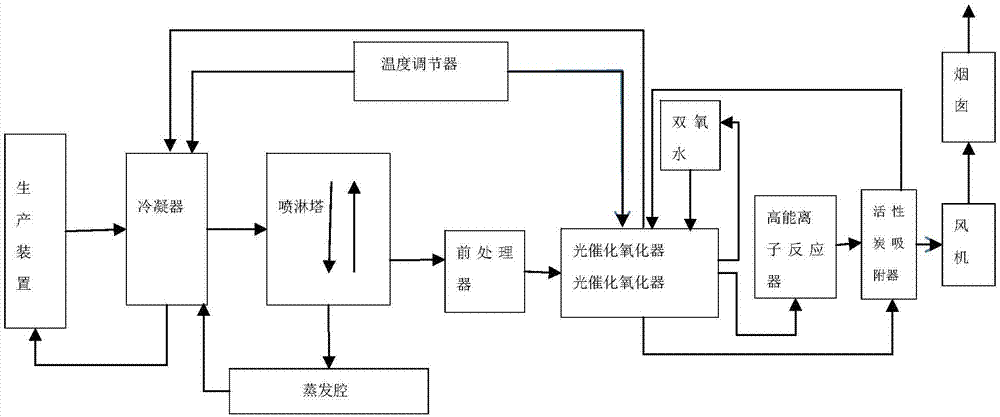

[0024] An oxidizable volatile organic compound treatment device provided in this embodiment includes a condenser, a spray tower, a photocatalytic oxidizer, a high-energy ion reactor, and an activated carbon adsorber connected in sequence, and a There is an air return pipe, and a pre-processor may also be arranged between the spray tower and the photocatalytic oxidizer, and a filter element is arranged in the pre-processor. There are two photocatalytic oxidizers, and the two photocatalytic oxidizers are connected in parallel. The condenser is connected with an exhaust port of the production device, the activated carbon adsorber is connected with an exhaust pipe, the exhaust pipe is connected with a chimney, and a fan is also arranged on the exhaust pipe. The lower part of the condenser is provided with a liquid collection tank, and the condenser is also provided with a liquid return pump, the liquid inlet pipe of the liquid return pump is inserted into the liquid collection tan...

Embodiment 2

[0028] This embodiment provides a method for using the above-mentioned oxidizable volatile organic compound treatment device. The activated carbon adsorber of the oxidizable volatile organic compound treatment device includes an adsorption chamber, and an installation frame is placed in the adsorption chamber, and the installation frame is filled with activated carbon fibers. The photocatalytic oxidizer includes a reaction tank, the reaction tank is provided with a sealed door, and a support is also provided in the reaction tank, and the installation frame equipped with activated carbon fibers can be placed on the support. After treating the exhaust gas, first take out the installation frame with activated carbon fiber, and immerse the installation frame with activated carbon fiber in hydrogen peroxide; then open the airtight door of the reaction tank, and place the installation frame with activated carbon fiber on the support ; Finally close the airtight door and open the swit...

Embodiment 3

[0031] This embodiment provides another method of using the above-mentioned oxidizable volatile organic compound treatment device. After treating the exhaust gas, first turn on the recovery pipe switch at the bottom of the spray tower, and the accumulated liquid in the spray tower flows into the evaporation through the recovery pipe. Then turn off the switch of the recovery pipe, turn on the switch of the steam discharge pipe and the heater in the evaporation chamber, and finally turn on the switch of the condenser to condense and recycle the volatile gas evaporated in the evaporation chamber, and the remaining solid matter after evaporation is deposited in the evaporation chamber Inside.

[0032]The above-mentioned method of using an oxidizable volatile organic compound treatment device can discharge the volatile organic compounds into the condenser for condensation and recovery through the evaporation chamber to evaporate the liquid in the lower part of the spray tower, incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com