Horizontal opened sofa cushion

A sofa cushion and lateral technology, applied in the field of sofa cushions, can solve the problems of easy slippage and displacement, easy deformation of the seat cushion, etc., and achieve the effects of improving ventilation and heat dissipation, improving comfort, and avoiding movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

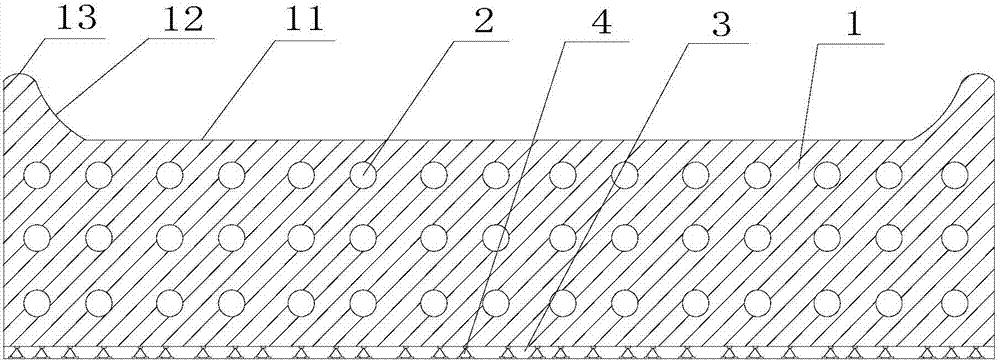

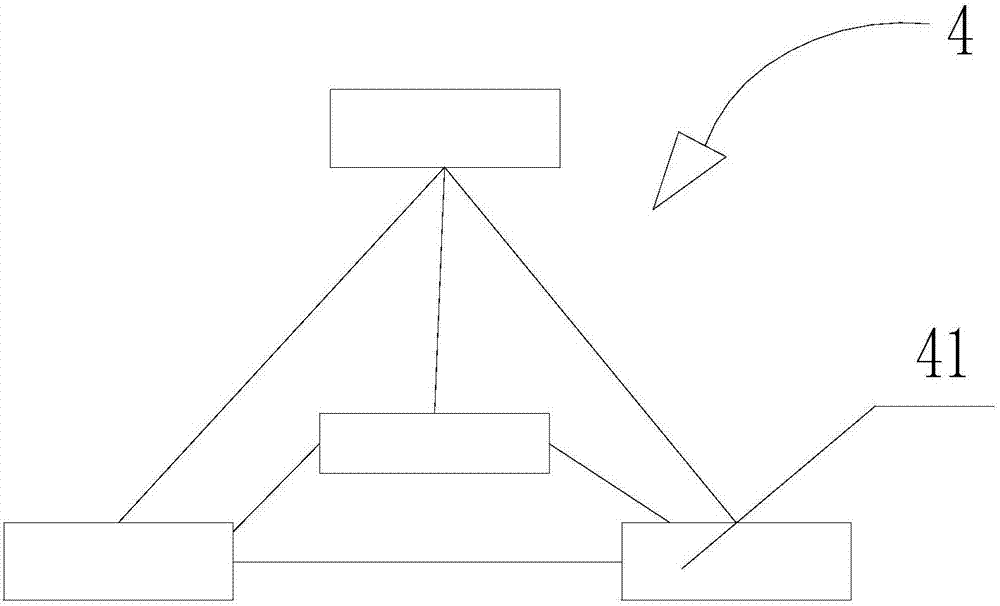

[0046] Such as figure 1 As shown, a sofa cushion with transverse openings includes a cushion core body 1, which is provided with a number of air holes 2, and the cushion core body 1 is made of a porous elastic material, and the air vent holes 2 The opening direction of the core body 1 is perpendicular to the stress direction of the core body 1, the inner wall of the air hole 2 is provided with a latex layer, and the air hole 2 is a circular hole or a square hole; the porous elastic material is Sponge; the bottom of the core body 1 is provided with an anti-slip layer 3, and an anti-slip block 4 is arranged in the anti-slip layer 3. The anti-slip block 4 is a tetrahedral structure, and a fixed block 41 is provided at the apex of the tetrahedral structure. The block 41 is connected with the upper top surface and the lower bottom surface of the anti-skid layer 3 .

Embodiment 2

[0048] Such as figure 1 As shown, this embodiment is based on embodiment 1, and the thickness of the latex layer is 1 / 10 of the inner diameter of the air hole 2; a spring is arranged in the air hole 2, and the spring is consistent with the force direction of the core body 1 The air holes 2 are evenly spaced, and the distance between adjacent air holes 2 is twice the inner diameter of the air holes 2.

Embodiment 3

[0050] Such as figure 1 As shown, this embodiment is based on Embodiment 1 or Embodiment 2. The upper end of the core body 1 is recessed downward to form a groove 11, the front end and the rear end of the groove 11 are the beginning, and the left end and the The right end has a side wall, the inner surface of the side wall is an arc surface 12, and the arc surface 12 and the bottom arc transition of the groove 11; the upper end surface of the side wall of the groove 11 is an arc surface 13, so The depth of the groove 11 is 60mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com