Liquid supplement method for cascaded utilization soft package lithium battery cell

A liquid replenishment method and lithium battery technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of reducing the service life of power batteries, reducing the use value of power batteries, and reducing cycle life, so as to improve circulation and alleviate The effect of reducing the capacity of the battery cell and reducing the internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

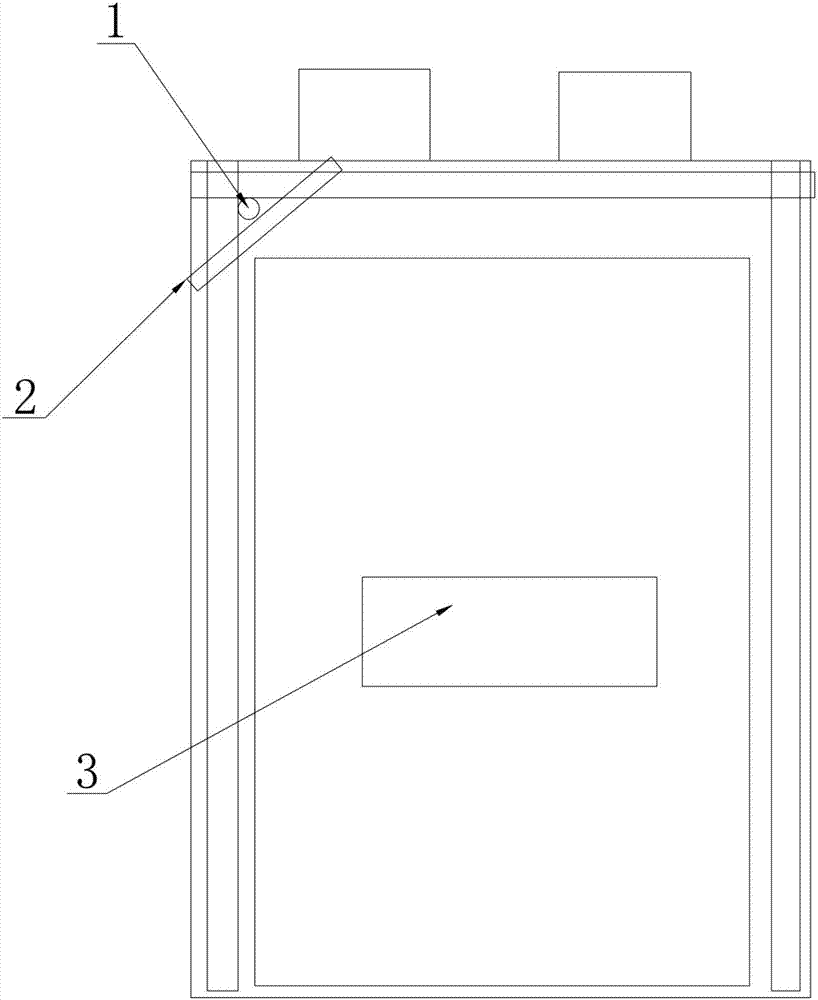

[0028] Such as figure 1 As shown, the decommissioned soft-packed power cell 3 is initially screened, the soft-packed power cell 3 with abnormal appearance is eliminated, and the soft-packed power cell 3 with qualified appearance is cyclically tested, and the capacity retention is high and the resistance is normal. The packaged power cell 3 is directly reused; the soft packaged power cell 3 with lower capacity and larger internal resistance is picked out for use; the decommissioned soft packaged power cell 3 has no requirements for size, and the retired soft packaged power cell The core 3 is the ternary cell 3. The soft-packed power cell 3 with lower capacity and larger internal resistance to be used is discharged to 2.5V, and then placed in a glove box with a dew point lower than -45℃, gloves The dew point in the box is controlled by the online dew point tester and the dehumidifier air supply dew point adjustment, and the electrolyte is refilled into the soft pack power cell 3 ...

Embodiment 2

[0030] Such as figure 1 As shown, the decommissioned soft-packed power cell 3 is initially screened, the soft-packed power cell 3 with abnormal appearance is eliminated, and the soft-packed power cell 3 with qualified appearance is cyclically tested, and the capacity retention is high and the resistance is normal. The packaged power cell 3 is directly reused; the soft packaged power cell 3 with lower capacity and large internal resistance is picked out for use; the decommissioned soft packaged power cell 3 has no requirements for size, and the retired soft packaged power cell The core 3 is a lithium iron phosphate battery 3. The soft-packed power battery 3 with lower capacity and larger internal resistance to be used is discharged to 2.5V, and then placed in a glove box with a dew point lower than -45°C. The dew point in the box is controlled by the online dew point tester and the dehumidifier air supply dew point adjustment, and the electrolyte is refilled into the soft pack p...

Embodiment 3

[0032] Such as figure 1 As shown, the decommissioned soft-packed power cell 3 is initially screened, the soft-packed power cell 3 with abnormal appearance is eliminated, and the soft-packed power cell 3 with qualified appearance is cyclically tested, and the capacity retention is high and the resistance is normal. The packaged power cell 3 is directly reused; the soft packaged power cell 3 with lower capacity and large internal resistance is picked out for use; the decommissioned soft packaged power cell 3 has no requirements for size, and the retired soft packaged power cell The core 3 is a lithium titanate battery 3. The soft-packed power battery 3 with lower capacity and larger internal resistance to be used is discharged to 2.5V, and then placed in a glove box with a dew point lower than -45℃. The dew point in the box is controlled by the online dew point tester and the dehumidifier air supply dew point adjustment. The electrolyte is refilled into the soft pack power cell 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com