A stacked organic electroluminescent device

An electroluminescent device, an organic technology, applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems that cannot be used as n-type dopants, active alkali metals are unstable, and affect the evaporation atmosphere of the chamber. , to reduce the preparation cost and operation complexity, reduce the LUMO energy level, and increase the number of free carriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

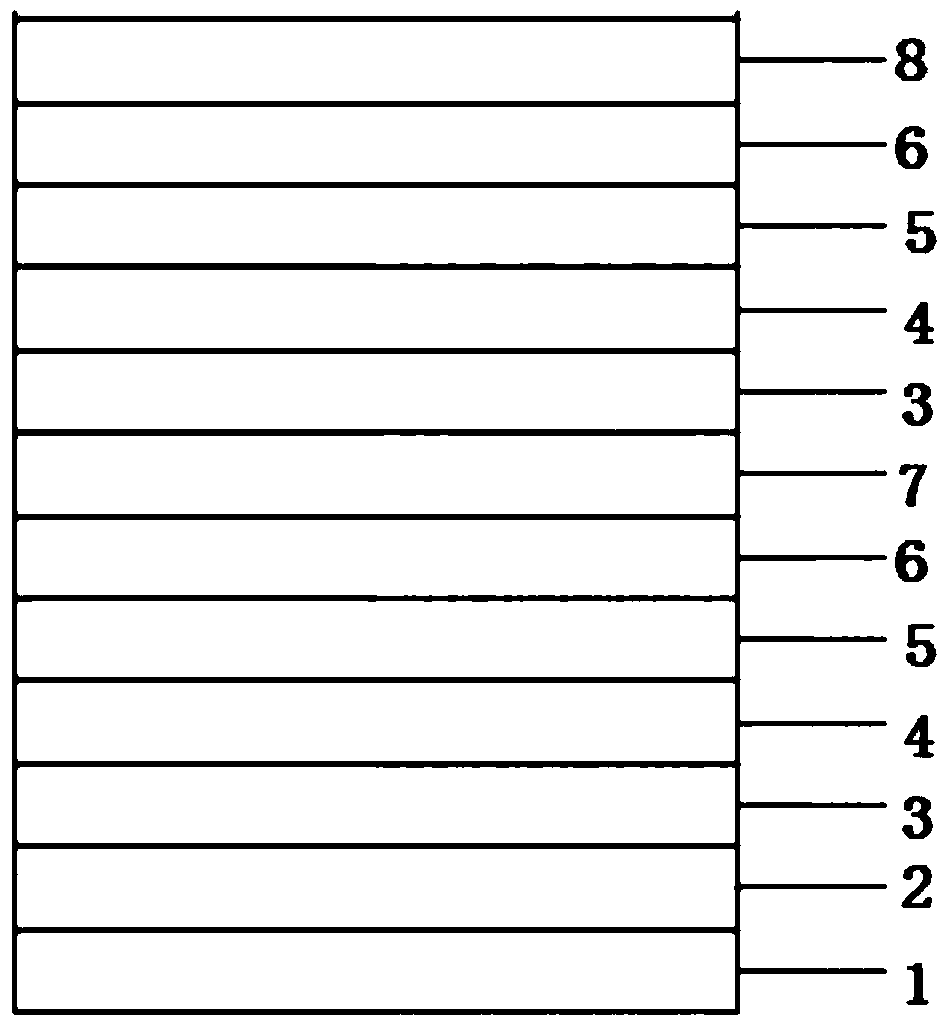

[0059] The structure of the device:

[0060] ITO / HATCN / NPB / Alq3 / Bphen(20nm) / x%Ag:Bphen(10nm) / HATCN / NPB / Alq3 / Bphen / Mg:Ag / Ag;

[0061] The first electrode layer 2 (ITO, anode), the hole injection layer 3 (HATCN), the hole transport layer 4 (NPB), the light emitting layer 5 (Alq 3 ), electron transport layer 6 (Bphen), electron generation layer 7 (x%Ag:Bphen), hole injection layer 3 (HATCN), hole transport layer 4 (NPB), light emitting layer 5 (Alq 3 ), electron transport layer 6 (Bphen), second electrode layer 8 (Mg:Ag / Ag)

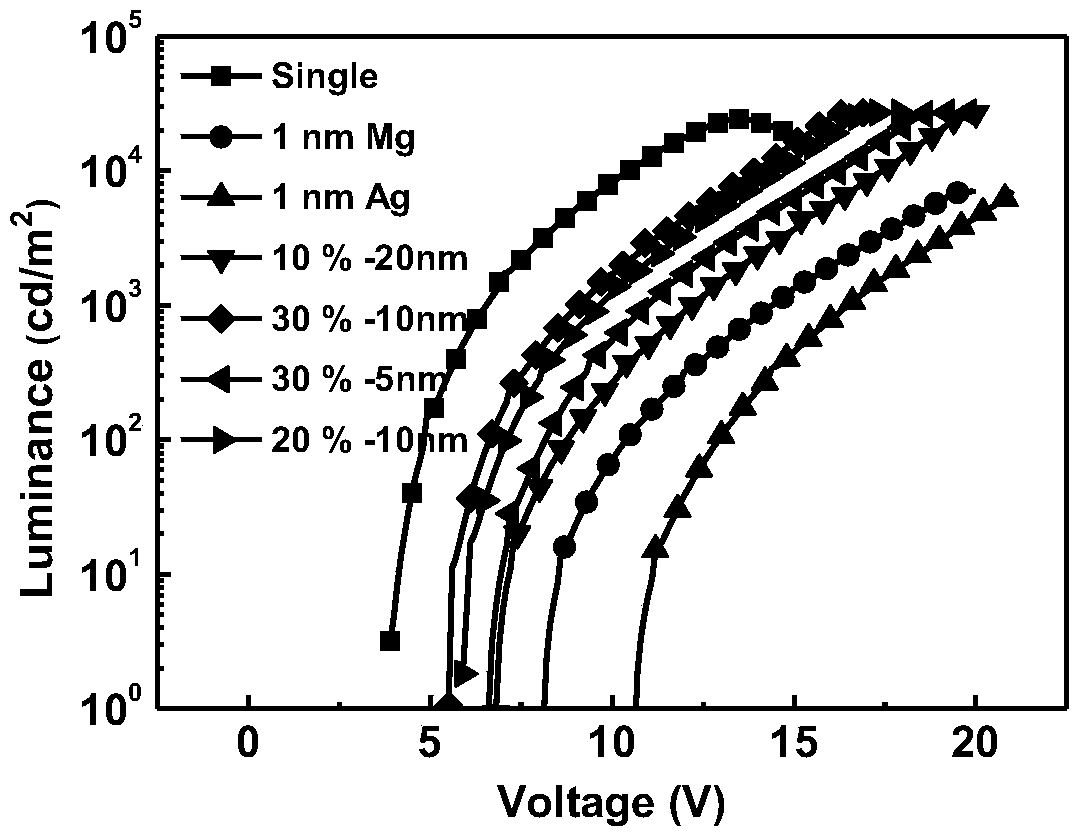

[0062] The host material of the electron generation layer 7 in the present embodiment is Bphen, and the doped inert metal is Ag, such as figure 2 Shown are the voltage-brightness curves from device 1 to device 7, where device 1 is the curve corresponding to single, device 2 is the curve corresponding to 1nm Mg, device 3 is the curve corresponding to 1nm Ag, and device 4 is the curve corresponding to 10%-20nm Device 5 is a curve corresponding to 30%-10nm,...

Embodiment 2

[0075] The structure of device 8 to device 33 is the same as that of device 1, wherein the composition of the electron transport layer and the electron generation layer is as follows:

[0076] Table 1 The composition of electron transport layer and electron generation layer of the present invention

[0077]

[0078]

Embodiment 3

[0080] The structure of device 32 to device 35 is the same as that of device 12, wherein the EMT in the electron transport layer and the electron generation layer adopts the compounds of the structures shown in formula (6-1), formula (6-2) and formula (6-3) respectively , the doped metals M are ruthenium Ru, rhodium Rh and lead Pb respectively, and the doping ratios are 20vol%, 30vol% and 40vol% respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com