Integrated soft detection circuit for speed and torque based on armature voltage and current signals

An armature voltage and current signal technology, applied in the field of industrial measurement and control, can solve the problems of undetectable load torque and time-varying load torque, poor dynamic accuracy, complex structure, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

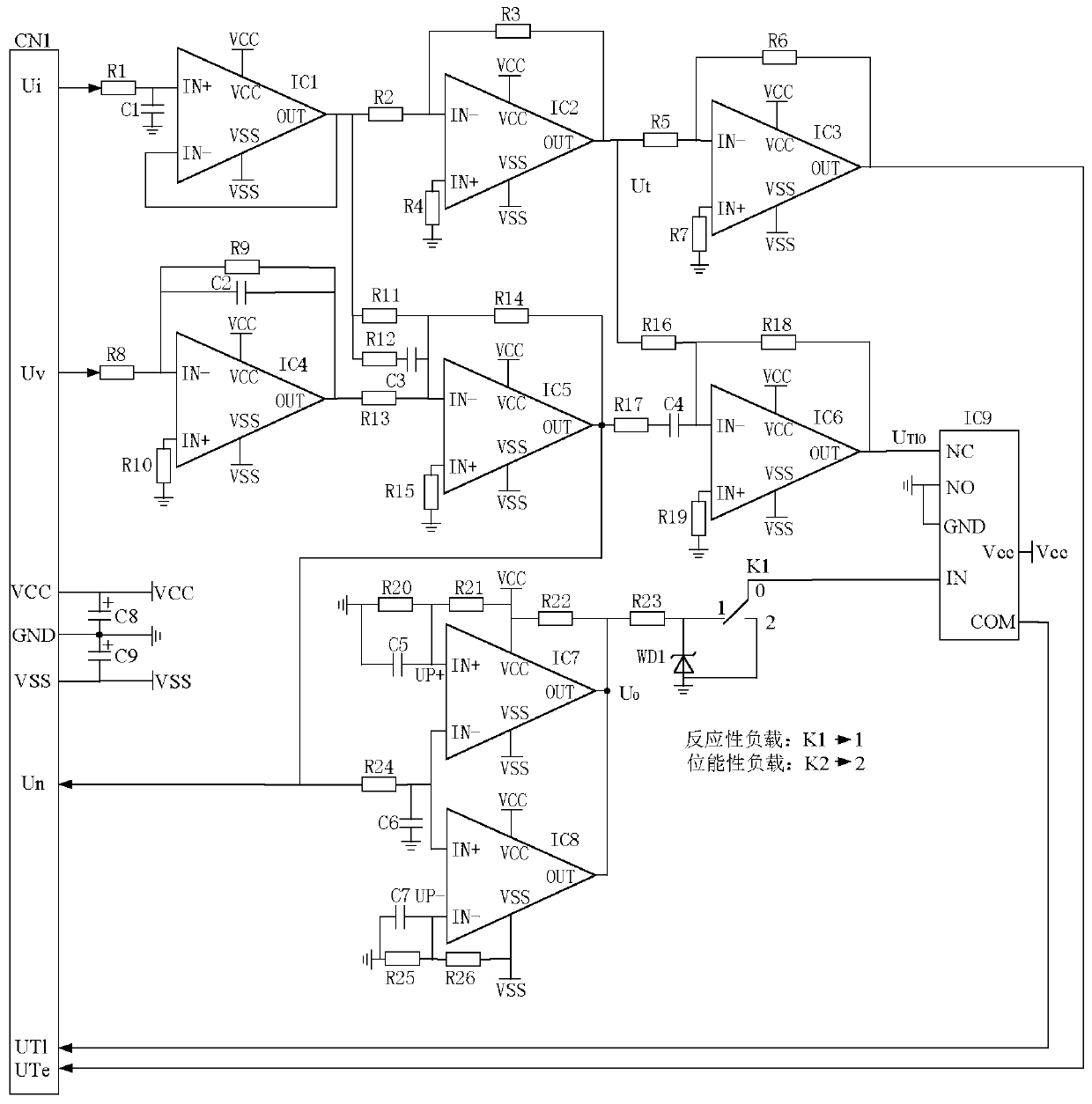

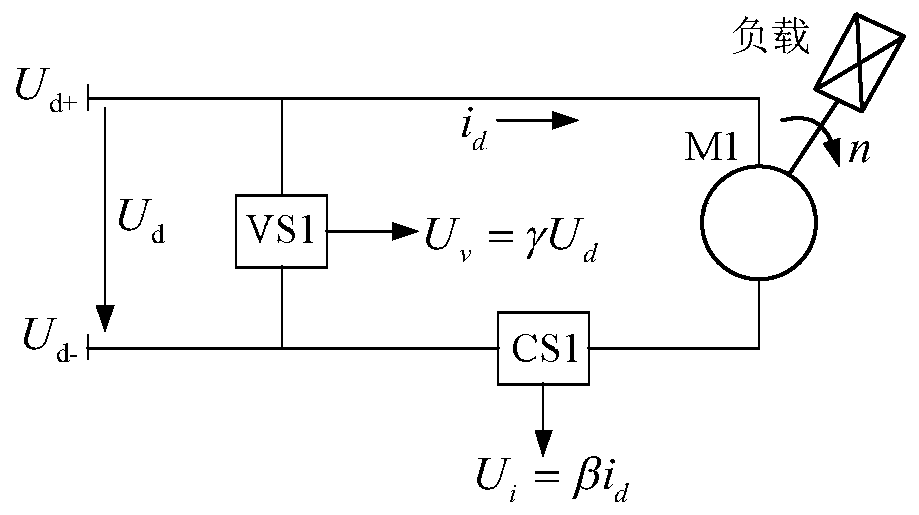

[0013] Such as figure 1 As shown, the load torque detection circuit based on the armature current and the speed signal includes a speed signal processing circuit, a comprehensive torque signal processing circuit, and a load type selection circuit.

[0014]Speed signal processing circuit includes connector CN1, current follower IC1, voltage amplifier IC4, armature amplifier IC5, upper input resistor R1, lower input resistor R8, lower feedback resistor R9, lower positive terminal resistor R10, proportional resistor R11, filter resistor R12, superposition resistor R13, differential resistor R14, compensation resistor R15, upper filter capacitor C1, lower filter capacitor C2, current differential capacitor C3, positive power supply capacitor C8, negative power supply capacitor C9, one end of the upper input resistor R1 and connector CN1 The current detection signal input ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com