Manufacturing method of colored decorating plate for whole bathroom

A manufacturing method and technology for decorative panels, which are applied in the application, flat products, household appliances, etc., can solve the problems of inability to make color decorative panels, single color, etc., and achieve the effects of high brightness, high surface effect, and simple process control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Follow the steps below to prepare the overall bathroom color decorative board:

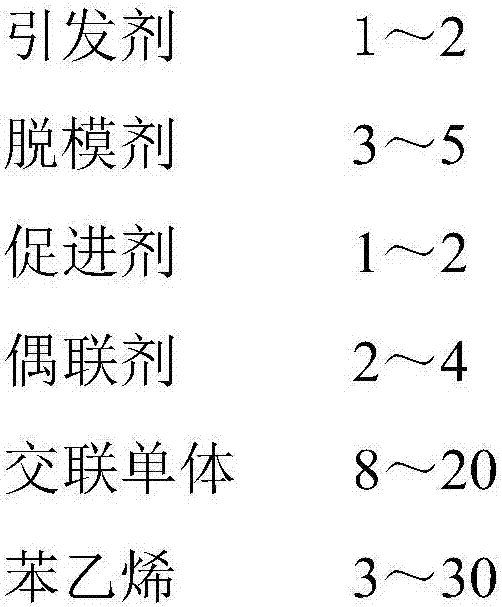

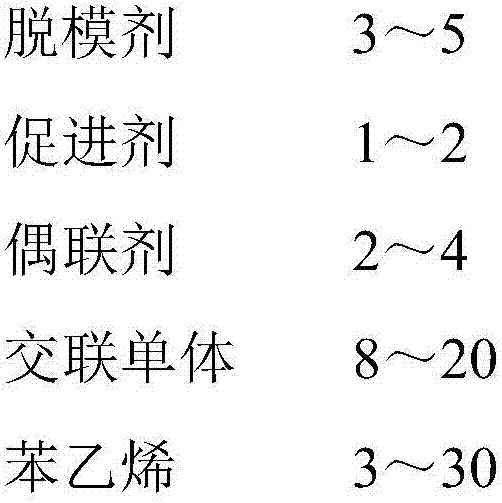

[0043] 1) Configure the resin paste according to the following formula (parts by mass):

[0044]

[0045]

[0046] After the above-mentioned raw materials are mixed uniformly to prepare the resin paste, add 10 parts of styrene to adjust the viscosity, so that the resin paste is properly diluted.

[0047] Apply the above resin paste evenly on the decorative fiber cloth with colored texture, the mass ratio of the resin paste to the decorative fiber cloth is roughly 1:1. Put the decorative fiber cloth coated with the resin paste into the drying tunnel at about 135°C Carry out pre-curing to ensure that its curing degree reaches about 80%, that is, the surface color decorative fiber material for the molded color decorative board is obtained;

[0048] 2) Prepare SMC sheet molding compound according to the following formula (mass parts)

[0049]

[0050] Mix evenly to make a paste.

[...

Embodiment 2

[0056] 1) Configure the resin paste according to the following formula (parts by mass):

[0057]

[0058] After the above-mentioned raw materials are mixed evenly to prepare the resin paste, 18 parts of styrene are added to adjust the viscosity, so that the resin paste is properly diluted.

[0059] Apply the above resin paste evenly on the decorative fiber cloth with colored texture, the mass ratio of the resin paste to the decorative fiber cloth is roughly 1:1. Put the decorative fiber cloth coated with the resin paste into the drying tunnel at about 135°C Carry out pre-curing to ensure that its curing degree reaches about 80%, that is, the surface color decorative fiber material for the molded color decorative board is obtained;

[0060] 2) Prepare SMC sheet molding compound according to the following formula (mass parts)

[0061]

[0062] Mix the above-mentioned raw materials evenly to prepare the paste.

[0063] Use a scraper to evenly coat the above paste on the u...

Embodiment 3

[0068] 1) Configure the resin paste according to the following formula (parts by mass):

[0069]

[0070] After the above raw materials are mixed uniformly to prepare the resin paste, add 15 parts of styrene to adjust the viscosity and properly dilute the resin paste.

[0071] Apply the above resin paste evenly on the decorative fiber cloth with colored texture, the mass ratio of the resin paste to the decorative fiber cloth is roughly 1:1. Put the decorative fiber cloth coated with the resin paste into the drying tunnel at about 135°C Carry out pre-curing to ensure that its curing degree reaches about 80%, that is, the surface color decorative fiber material for the molded color decorative board is obtained;

[0072] 2) Prepare SMC sheet molding compound according to the following formula (mass parts)

[0073]

[0074]

[0075] Mix the above-mentioned raw materials evenly to prepare the paste.

[0076] Use a scraper to evenly coat the above paste on the upper and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com