Water-washing device for blanket

A technology for washing equipment and blankets, which is applied to the equipment configuration of textile materials, textile and papermaking, liquid/gas/steam textile processing, etc. and other problems to achieve the effect of improving quality and use effect, improving cleaning quality and suitable promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

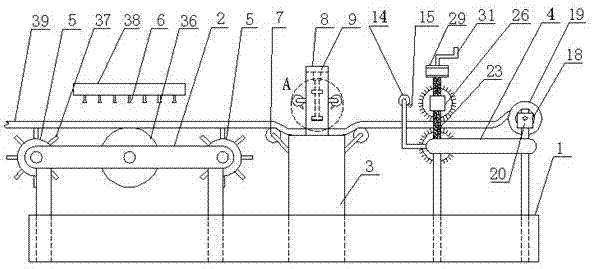

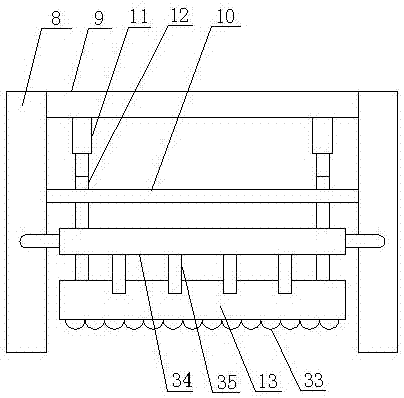

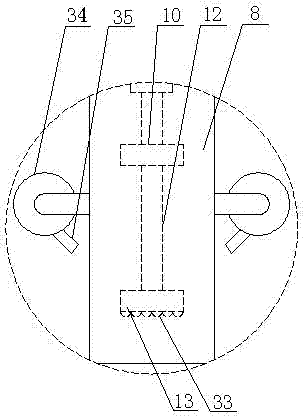

[0023] like Figure 1 to Figure 5 As shown, a blanket washing device includes a water tank 1, in which a frame A2, a beating table 3 and a frame B4 are sequentially arranged from left to right, feed rollers 5 are arranged at both ends of frame A, and frame A There is a support roller 36 on the top, which is located between the two feed rollers. Since the weight of the felt increases after it is soaked in water, the support roller prevents the felt from drooping and affects normal conveying. A plurality of strip plates 37 are uniformly arranged on the feed roller. , the strip plate and the feed roller extend in the same direction to avoid slipping between the feed roller and the felt. There is a spray pipe A38 above the frame A, and a nozzle A6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com