Environment-friendly polyvinyl chloride material composition as well as preparation method and application thereof

A technology of material composition and polyvinyl chloride, applied in the field of new materials, can solve the problems of high price and large environmental impact, and achieve the effect of low cost, good gloss and high flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

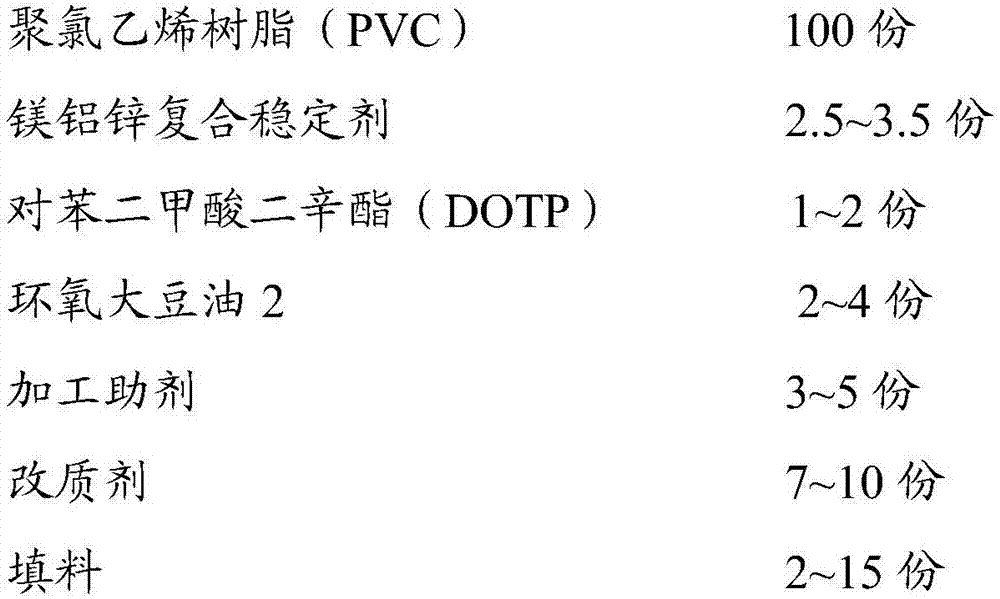

[0027] In this embodiment, an environment-friendly polyvinyl chloride material composition comprises the following raw material components in parts by weight:

[0028] Table 1

[0029]

[0030] The preparation method of above-mentioned environment-friendly polyvinyl chloride material composition, comprises the steps:

[0031] 1) Weigh various raw material components according to the formula in the above table, and put them in order according to PVC powder → titanium dioxide, colorant → magnesium-aluminum-zinc composite stabilizer, DOTP, epoxy soybean oil → processing aid, MBS, talc powder → The hot mixer runs at low speed, and then the mixer runs at high speed. When the temperature of the material rises to 100-105°C, the material is automatically discharged into the cold mixer.

[0032] 2) In the cold mixer, the material is rapidly cooled and further mixed evenly. When the temperature of the material is cooled to 75-80°C, the material is manually discharged into the storag...

Embodiment 2

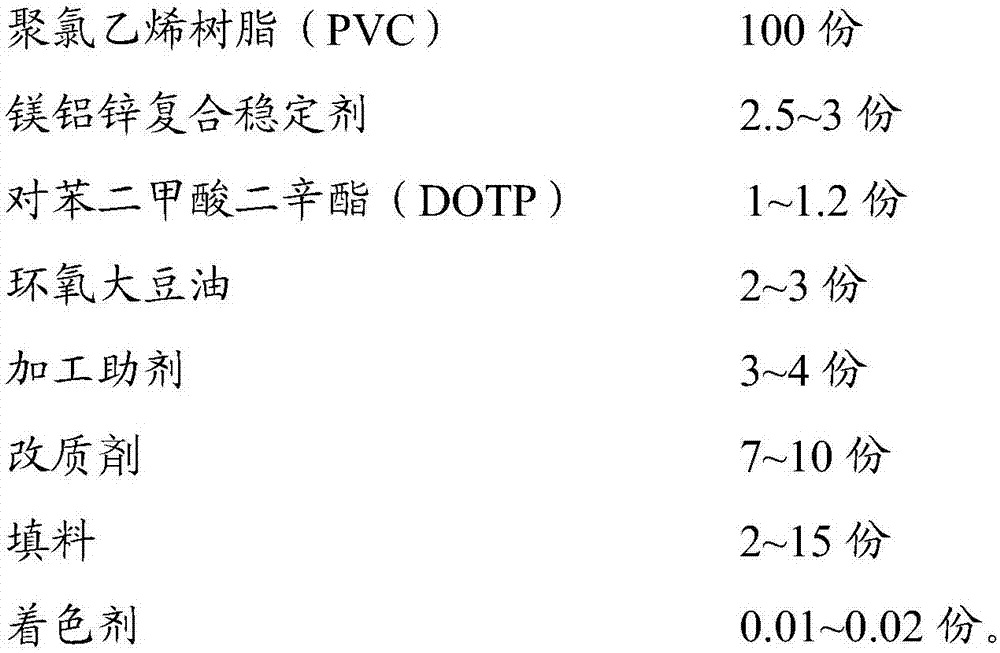

[0039] In this embodiment, an environment-friendly polyvinyl chloride material composition comprises the following raw material components in parts by weight:

[0040] Table 2

[0041]

[0042]

[0043] The preparation method of the above environment-friendly polyvinyl chloride material composition is the same as that in Example 1.

Embodiment 3

[0045] In this embodiment, an environment-friendly polyvinyl chloride material composition comprises the following raw material components in parts by weight:

[0046] table 3

[0047]

[0048] The preparation method of the above environment-friendly polyvinyl chloride material composition is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com