High-performance calcium carbonate used for stone slabs and preparation method of high-performance calcium carbonate

A calcium carbonate, high-performance technology, applied in the field of modified calcium carbonate preparation, can solve the problems of calcium carbonate hydrophilic and oleophobic, poor dispersibility, poor compatibility with stone plates, etc., and achieves good modification effect and good dispersibility. , the effect of small agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

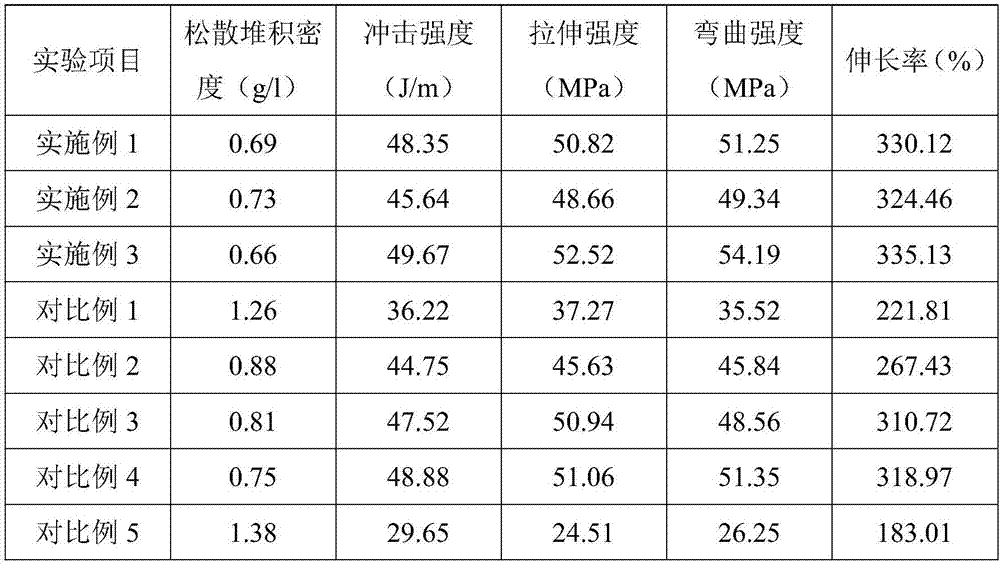

Examples

preparation example Construction

[0030] The preparation method of high-performance calcium carbonate for the stone slab comprises the following steps:

[0031] S1: Select marble, limestone, etc. transported from the material field to clean and remove impurities, dry the stone to remove surface moisture, and then use a crusher to crush the stone to obtain calcium carbonate fragments;

[0032] S2: transporting the broken calcium carbonate obtained in step S1 into a vertical mill and synchronously adding grinding aids and grinding to obtain calcium carbonate fine stone powder;

[0033] S3: classifying the calcium carbonate fine stone powder prepared in step S2 with a classifier to obtain calcium carbonate powder of 400-600 mesh;

[0034] S4: Add the calcium carbonate powder obtained in step S3 into a high-speed mixer, then add sodium dioctyl succinic acid sulfonate, stannous chloride, and magnesium oxide, raise the temperature to 92-103°C, and heat at 1100-1300r / Stir at a high speed of 24-28min at a speed of 2...

Embodiment 1

[0039]A kind of high-performance calcium carbonate for stone slabs, in parts by weight, comprising the following raw materials: 156 parts of broken calcium carbonate, 4.5 parts of grinding aid, 4 parts of sodium dioctyl succinate sulfonate, 0.5 part of stannous chloride , 0.1 part of magnesium oxide, 0.7 part of sodium diethylenetriaminepentacarboxylate, 0.1 part of acrylate regulator, 0.5 part of 3-aminopropyltriethoxysilane, bis(2-ethylhexyl) phthalate 1.8 parts of ester, 0.4 part of modified polyacrylate, 0.3 part of hexenylbisstearamide, 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole 0.5 parts, 0.22 parts of polyacrylamide, 0.5 parts of stabilizer;

[0040] The grinding aid, in parts by weight, comprises the following raw materials: 14 parts of potassium lignosulfonate, 7 parts of polyalcoholamine, and 8 parts of zinc stearate;

[0041] The preparation method of high-performance calcium carbonate for the stone slab comprises the following steps:

[0042]...

Embodiment 2

[0049] A high-performance calcium carbonate for stone slabs, in parts by weight, comprising the following raw materials: 143 parts of broken calcium carbonate, 3.6 parts of grinding aids, 3.2 parts of sodium dioctyl succinate sulfonate, and 0.3 parts of stannous chloride , 0.1 part of magnesium oxide, 0.5 part of sodium diethylenetriaminepentacarboxylate, 0.1 part of acrylate regulator, 0.4 part of 3-aminopropyltriethoxysilane, bis(2-ethylhexyl) phthalate 1.2 parts of ester, 0.3 part of modified polyacrylate, 0.2 part of hexenylbisstearamide, 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole 0.32 parts, 0.18 parts of polyacrylamide, 0.34 parts of stabilizer;

[0050] The grinding aid, in parts by weight, comprises the following raw materials: 12 parts of potassium lignosulfonate, 5 parts of polyalcoholamine, 6 parts of zinc stearate;

[0051] The preparation method of high-performance calcium carbonate for the stone slab comprises the following steps:

[0052] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com