A kind of method for reducing sulfur content of nickel-cobalt-aluminum precursor

A nickel-cobalt-aluminum and precursor technology, applied in chemical instruments and methods, nickel compounds, inorganic chemistry, etc., can solve problems such as difficulty in meeting the requirements of impurity sulfur content, poor sulfate removal effect, etc., and achieve low cost and efficiency. High, maneuverable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

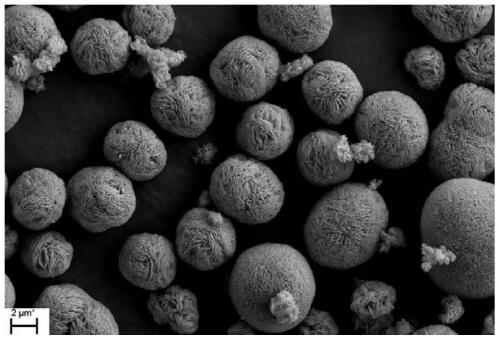

[0027] (1) Pass nickel-cobalt-aluminum mixed metal solution, sodium hydroxide, and ammonia water into the reaction kettle at the same time, and control the feed rate so that the residence time of the reaction is 20h-22h, the reaction temperature is 59°C-61°C, and the pH value is 11.00- 11.10, ammonia value 7.5g L -1 -8.0g·L -1 , stirring speed 600rpm-610rpm, N 2 atmosphere, to obtain nickel-cobalt-aluminum precursor precipitation and mother liquor, remove the mother liquor to obtain nickel-cobalt-aluminum precursor, and its FESEM photo is attached figure 1 shown.

[0028] (2) Transfer the nickel-cobalt-aluminum precursor in step (1) to the washing kettle for washing. There are 2 baffles inside the washing kettle, which are evenly distributed; the stirring paddle is 1 layer, and the bottom stirring paddle is push-type Stirring paddles; the number of paddle blades of each layer of stirring paddles is 3.

[0029] (3) Slurry washing: add the washing solution into the washing k...

Embodiment 2

[0033] (1) Pass the nickel-cobalt-aluminum mixed metal solution, sodium hydroxide, and ammonia water into the reaction kettle at the same time, and control the feed rate so that the residence time of the reaction is 30h-32h, the reaction temperature is 54°C-56°C, and the pH value is 10.80- 10.90, ammonia value 6.0g·L -1 -6.5g·L -1 , stirring speed 650rpm-660rpm, N 2 atmosphere to obtain nickel-cobalt-aluminum precursor precipitation and mother liquor, and remove the mother liquor to obtain the nickel-cobalt-aluminum precursor.

[0034] (2) Transfer the nickel-cobalt-aluminum precursor in step (1) to the washing kettle for washing. There are 4 baffles inside the washing kettle, which are evenly distributed; the stirring paddles are 2 layers, and the bottom stirring paddles are push-type Stirring paddles; the number of paddle blades of each layer of stirring paddles is 4.

[0035] (3) Slurry washing: add the washing solution into the washing kettle, and start stirring. Washi...

Embodiment 3

[0039] (1) Pass nickel-cobalt-aluminum mixed metal solution, sodium hydroxide, and ammonia water into the reaction kettle at the same time, and control the feed rate so that the residence time of the reaction is 12h-14h, the reaction temperature is 48°C-50°C, and the pH value is 11.25- 11.35, ammonia value 9.5g L -1 -10g·L -1 , stirring speed 690rpm-700rpm, N2 atmosphere to obtain nickel-cobalt-aluminum precursor precipitation and mother liquor, and remove the mother liquor to obtain the nickel-cobalt-aluminum precursor.

[0040] (2) Transfer the nickel-cobalt-aluminum precursor in step (1) to the washing kettle for washing. There are 8 baffles inside the washing kettle, which are evenly distributed; the stirring paddles are 3 layers, and the bottom stirring paddles are push-type Stirring paddles; the number of paddle blades of each layer of stirring paddles is 4.

[0041] (3) Slurry washing: add the washing solution into the washing kettle, and start stirring. The washing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com