Multifunctional 3D printing spray head based on internet of things

A 3D printing and multi-functional technology, applied in the direction of 3D object support structure, coating device, additive manufacturing, etc., can solve the problems of reducing the market value of 3D printers, complex structure of indicator light control circuit, and increase of production cost, etc. Performance, ingenious design, and practicality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

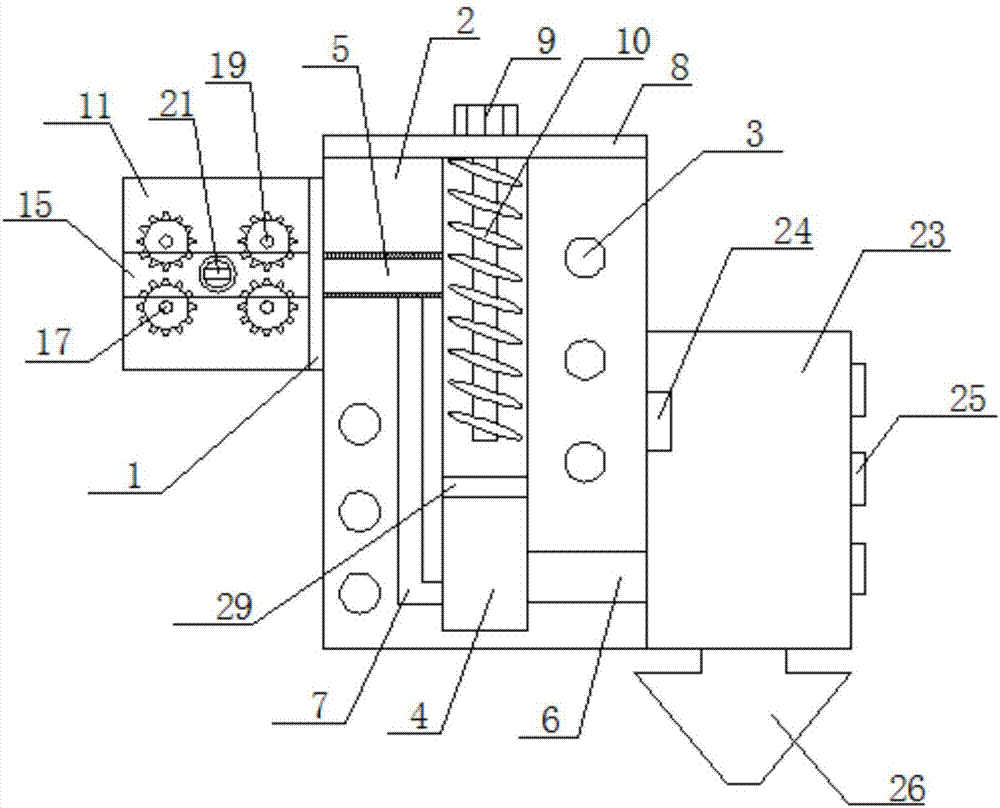

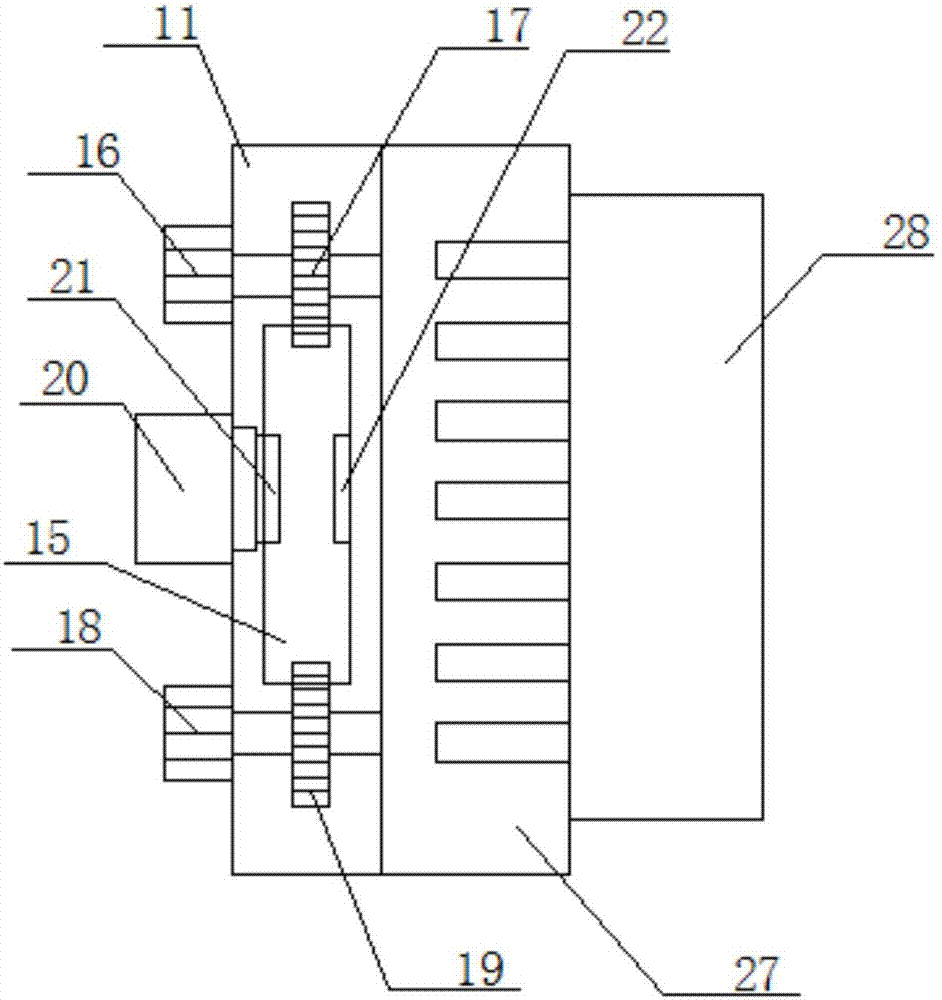

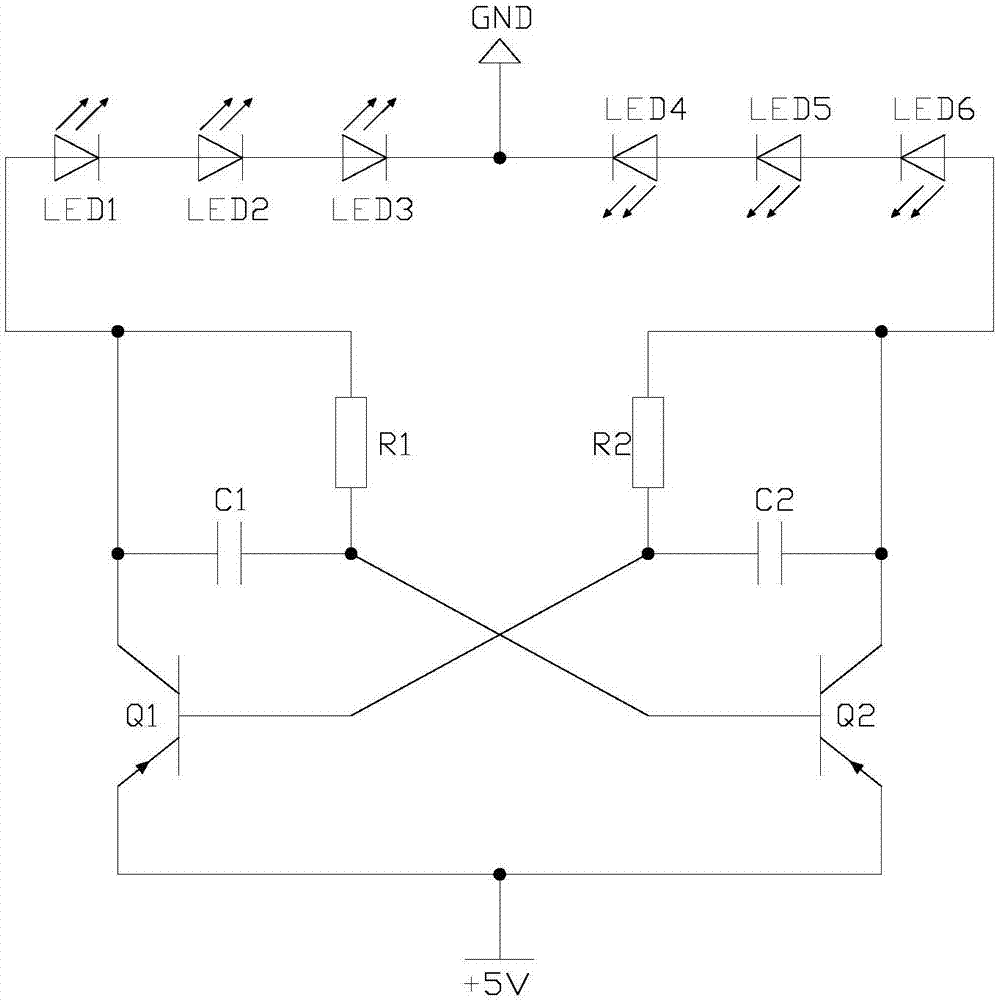

[0031] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0032] Such as Figure 1-4 As shown, a multifunctional 3D printing nozzle based on the Internet of Things, including a feeding mechanism, a heating mechanism and a lighting control module;

[0033]The feeding mechanism and the lighting control module are respectively located on both sides of the heating mechanism, and a heat insulating sheet 1 is arranged between the feeding mechanism and the heating mechanism;

[0034] The heating mechanism includes a body 2, a stirring assembly arranged on the body 2, and several first heaters 3, and the body 2 is provided with a stirring tank 4, a feed channel 5, a discharge channel 6 and an overflow prevention channel 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com