Bamboo section and intersection composite material and manufacturing method thereof

A production method and composite material technology, applied in mechanical equipment, sugarcane mechanical processing, etc., can solve the problems of stagnation of original bamboo products, high product cost, difficulty in large-scale industrialization, etc., to overcome the inconsistency of the radian, simple and practical to manufacture strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

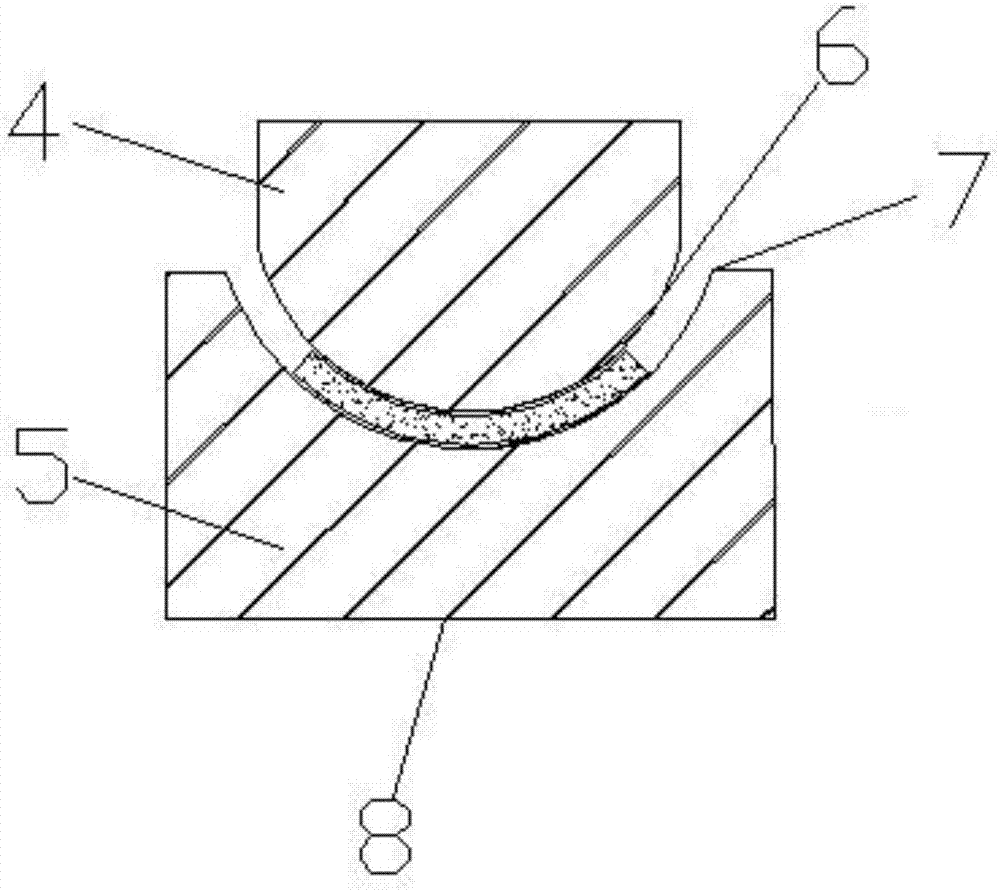

[0039] The bamboo joint of present embodiment, the manufacture method of internode composite material are as follows:

[0040] Step 1. Cut off the middle section of the felled bamboo, the length of the middle section is 600±1cm, the diameter of the bottom of the bamboo tube is 10±0.5cm, and the diameter of the end is 8±0.5cm; usually, the position about 1 meter away from the bamboo root is due to If there are too many knots and the texture is hard, they will be cut off for other purposes; go to step 2;

[0041] Step 2, divide the middle section into several bamboo segment units, each bamboo segment unit includes two internodes and a bamboo node connecting the two internodes, the length of a single internode is greater than 30cm; go to step 3;

[0042] Step 3, divide the bamboo section into four equal parts along the circumference, and obtain four bamboo pieces with the same length, width and radian; go to step 4;

[0043] Step 4. Make arc-shaped standardized bamboo sheets——Pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com