Manual vegetable cutting machine

A vegetable cutter and manual technology, which is applied in metal processing and other directions, can solve the problems of high friction of the rotating structure, unsatisfactory cutting effect, and stuck rope, and achieves fast and reliable transmission, uniform size and fast vegetable cutting speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

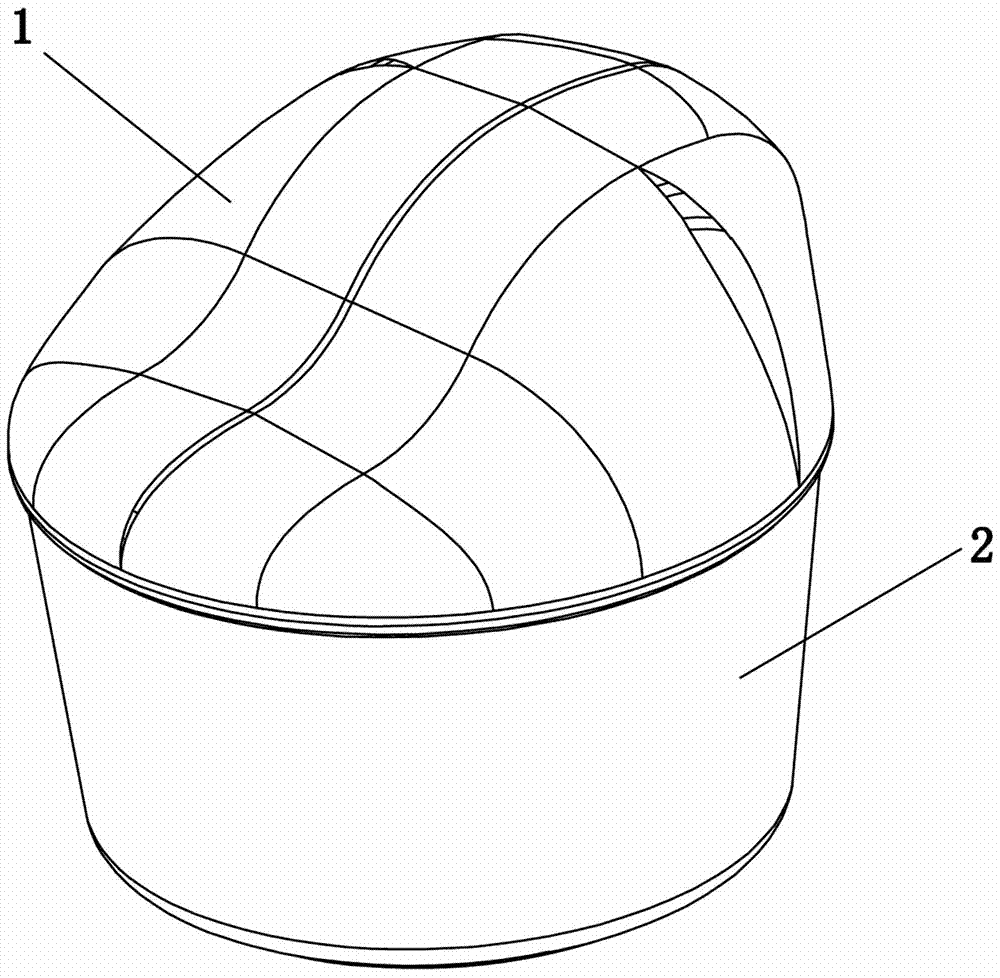

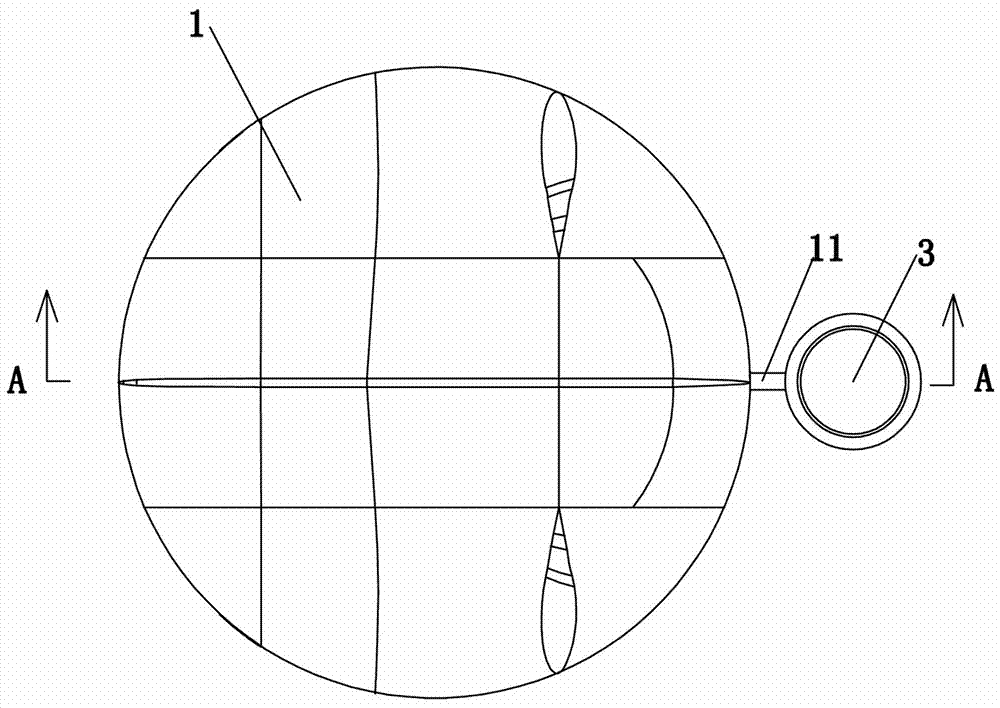

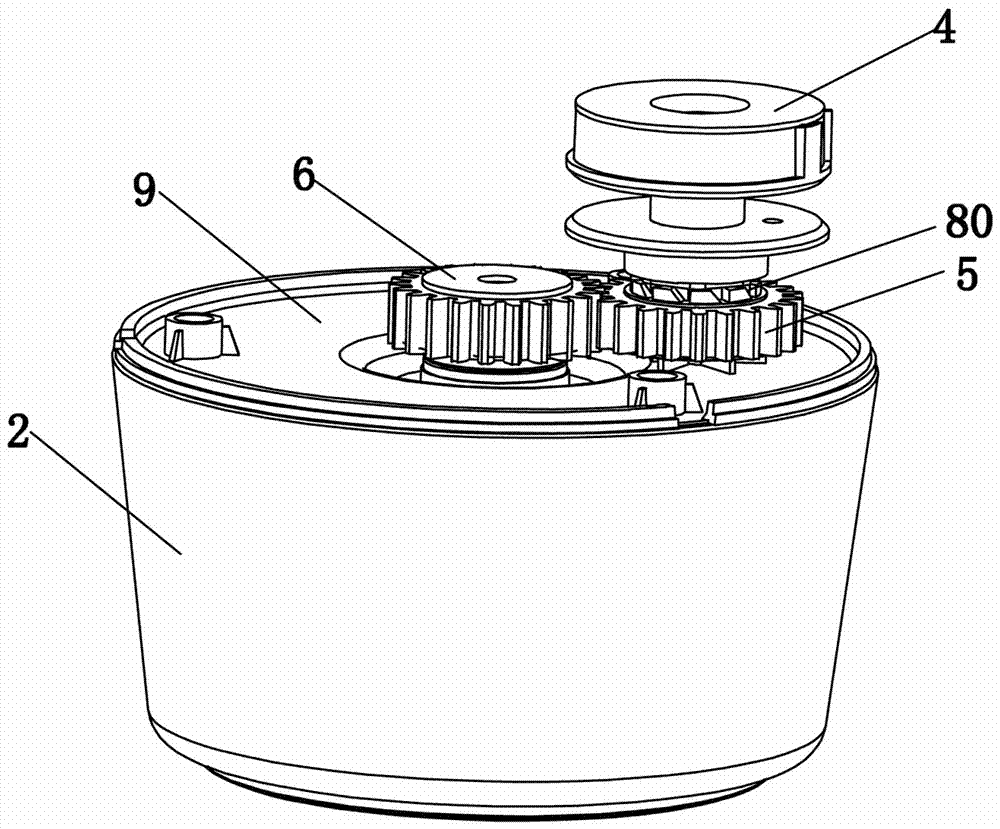

[0031] see Figure 1 to Figure 7 As shown, a manual vegetable cutter includes a cup body 1, a cutter 19, a cutter shaft and a cup cover 2, the cutter shaft 20 is installed in the cup body 1, the cutter 19 is arranged on the cutter shaft 20, and the cup cover 2. The cover is set on the opening of the cup body 1. The cup cover 2 includes an upper cover 10, a lower cover 9, a rope puller 3, a winding rope 11, a winding rope drum 4, a torsion spring 23, a spring 12, and an active ratchet plate 7 , the driving gear 5, and the driven gear 6, the upper cover 10 and the lower cover 9 are connected up and down to form a cup lid inner chamber 101, and the rope reel 4 is rotated and arranged in the cup lid inner chamber 101, and the rope 11 is wound On the rope reel 4, the outer end of the reel 11 is connected to the cord puller 3, the inner end of the reel is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com