AP1000 main steam pipeline welding method

A welding method and main steam technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as hidden dangers to the health and safety of operators and difficult installation of inflatable protection devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

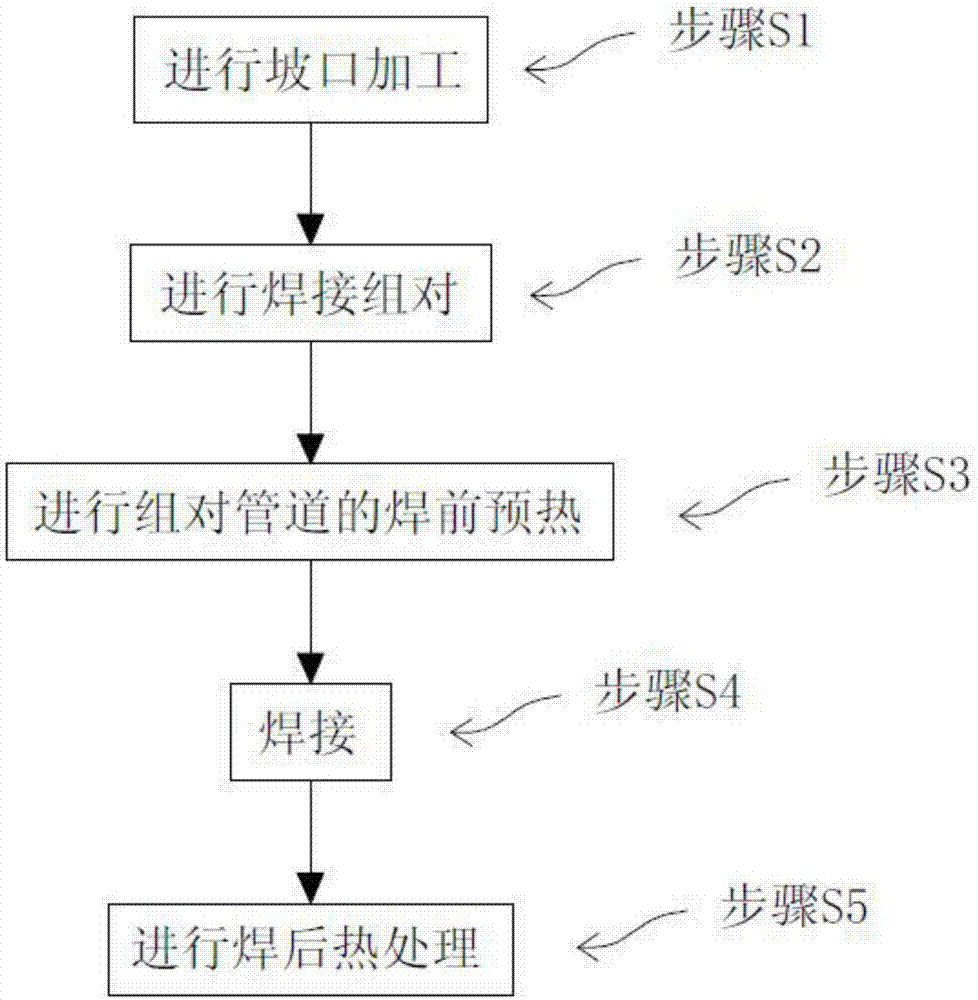

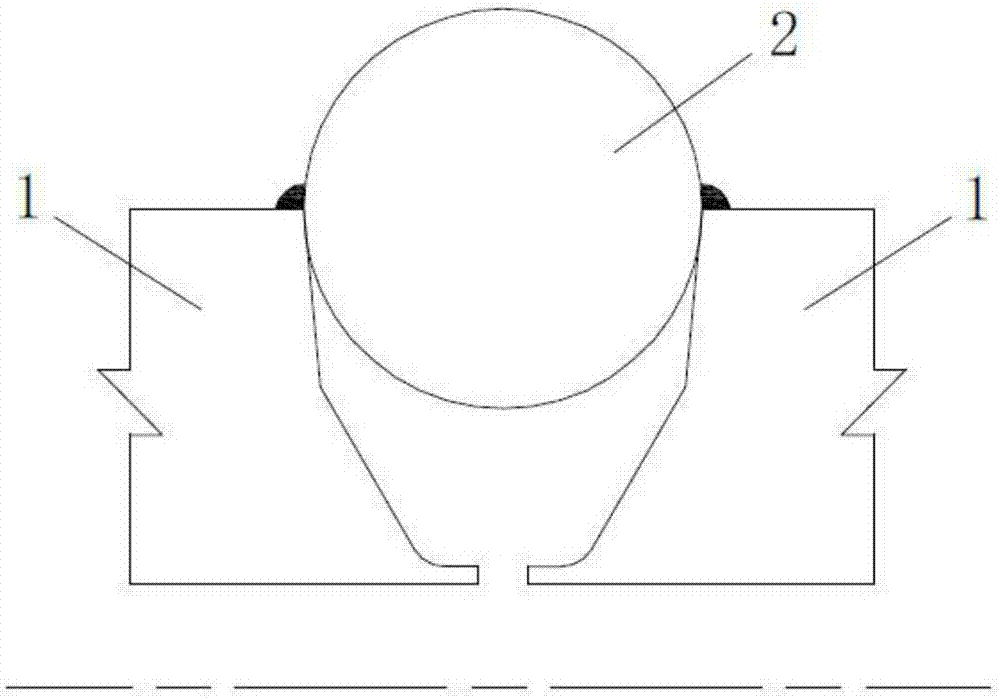

Method used

Image

Examples

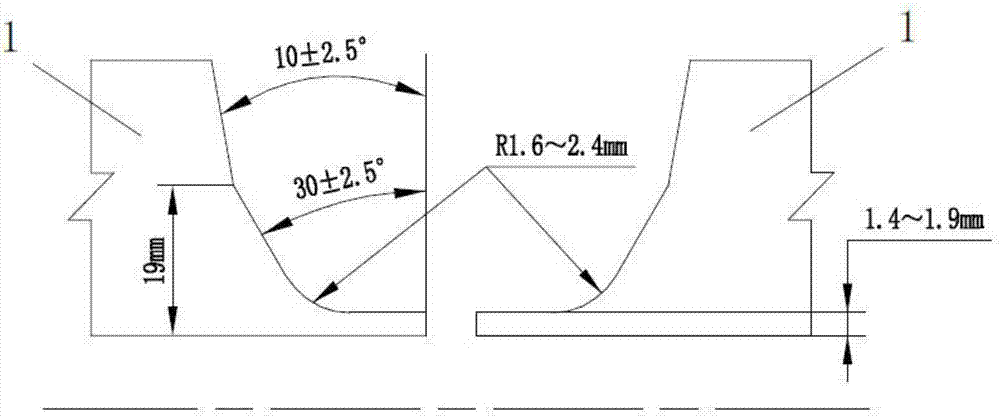

Embodiment 1

[0059] Embodiment 1, groove parameters: the height of the blunt side of the groove is 1.5 mm, and the radius of the arc at the root of the groove is 2.0 mm. Bottom welding parameters: the welding current in the area corresponding to the 6 o'clock-4 o'clock and the 6 o'clock-8 o'clock scale is 140A, and the argon gas flow rate is 20L / min; the welding current in the area corresponding to the 4 o'clock-3 o'clock and 8 o'clock-9 o'clock scale The welding current is 125A, the argon gas flow rate is 18L / min; the welding current in the area corresponding to the 3 o’clock-1 o’clock and the 9 o’clock-11 o’clock scale is 120A, and the argon gas flow rate is 15L / min; 1 o’clock-12 o’clock and 11 o’clock-12 o’clock The welding current in the area corresponding to the scale is 115A, and the flow rate of argon gas is 13L / min. Filler welding and cover welding parameters: the diameter of the welding wire is 2.4mm, the welding current is 180A, the welding voltage is 25V, and the welding speed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com