Adhesive Corner Prefabrication and Integrated Infusion Molding Process

A technology of infusion molding and bonding angle, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of long blade production cycle, difficult observation of the trailing edge glue, easy to blow up, etc., so as to reduce the flow time of the blade. , The effect of avoiding tooling indentation defects and improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

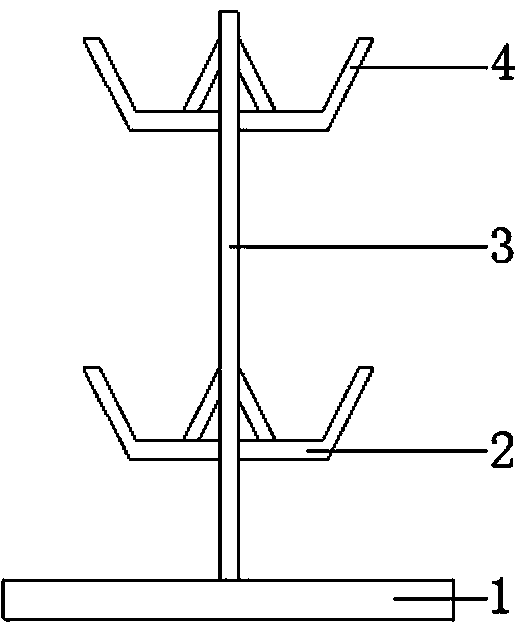

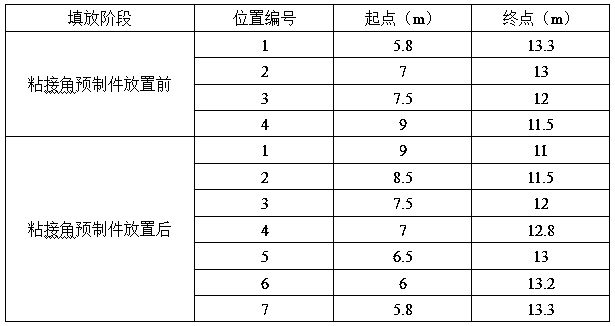

[0026] Embodiment: Taking the production of megawatt-level wind power blades with a length of 54.38m as an example

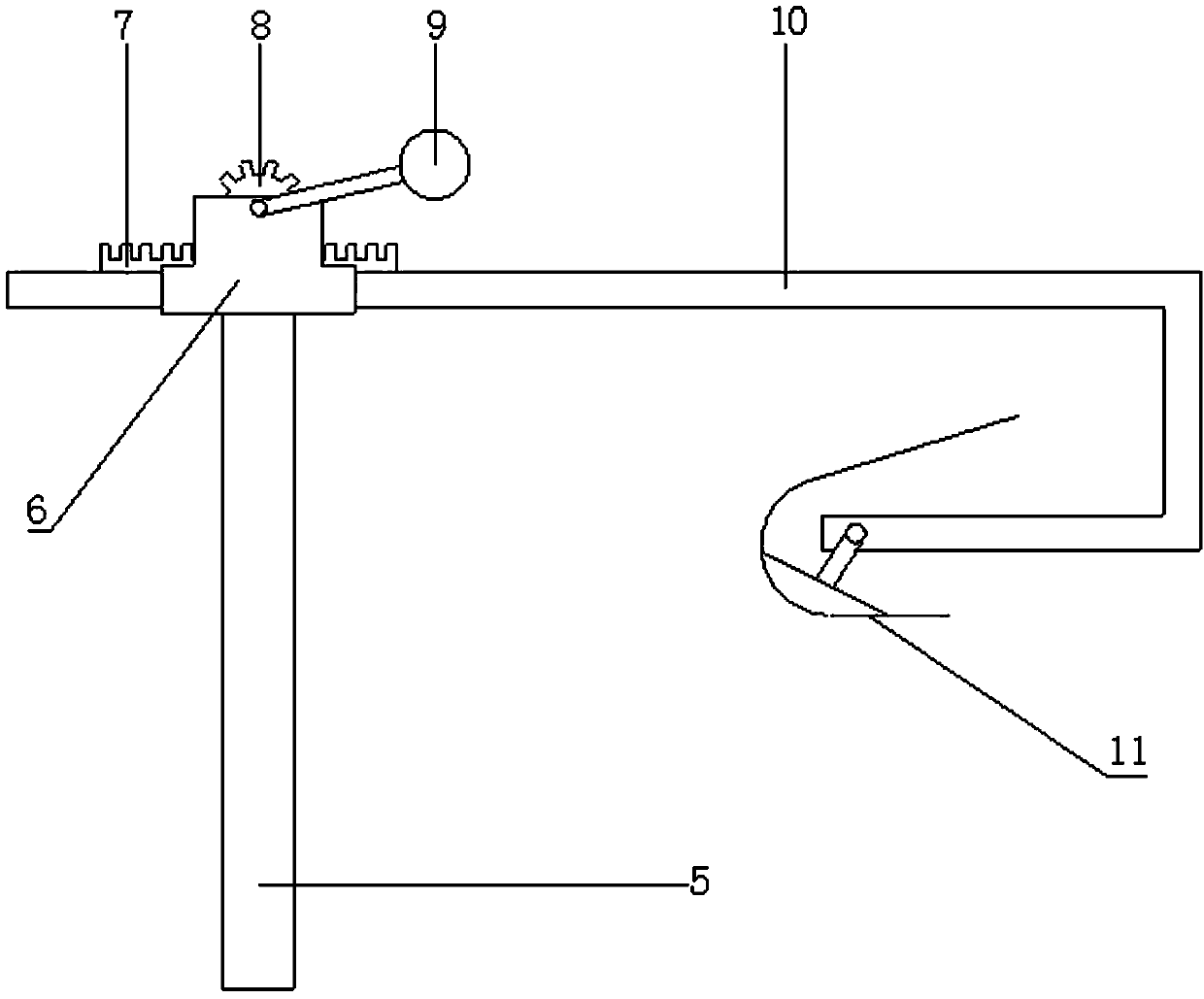

[0027] (1) Fabrication of adhesive angle molds: maintain the adhesive angle structure, divide the adhesive angle simulated cloth layer into two according to the clamping seam, and then lay and pour them on the windward side and the leeward side of the mold with skin; Surface bonding angle simulates the cloth layer and scrapes the triangle rubber type with a thickness of 2.0-4.0mm and a width of 30-50mm, and then glues the windward side to the mold. After curing, the mold is demoulded to obtain the male mold; use an angle grinder 1. Clean the burrs on the inner side of the male mold with a peak steel knife, apply a release agent, lay a porous film, cut the glass fiber cloth and pour it into the mold, and heat and cure it to demould to obtain a prefabricated mold for the bonding angle;

[0028] (2) Bonding angle prefabrication: use the bonding angle prefabricated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com